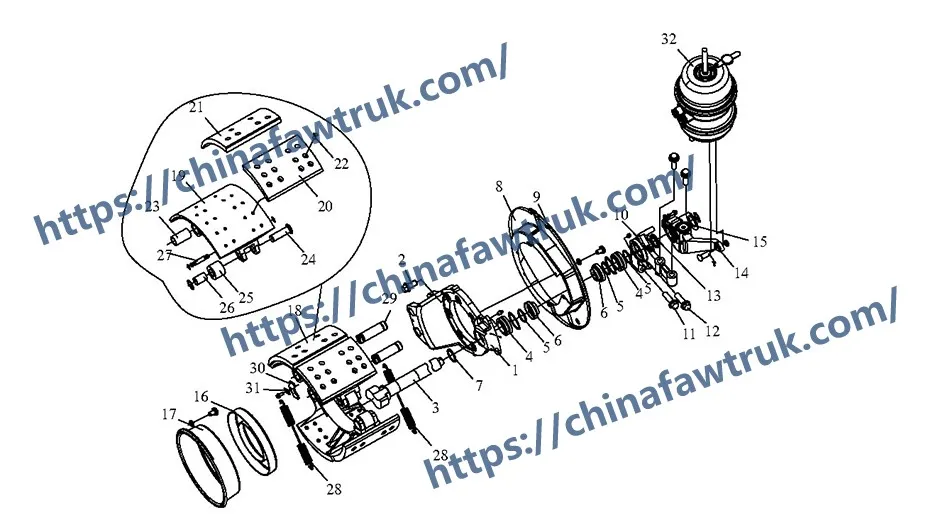

Il s'agit d'un guide technique complet sur le Frein de roue central FAW J6P (Model 3503025-A6E) Pour le FAW Jiefang CA3250P66K2L1T1E 6×4 tombereau. Cette déconstruction analyse 32 serviceable component types that form the complete S-cam brake assembly for the middle (avant) drive axle.

Le Frein de roue central FAW J6P est un véhicule robuste, Arnaque “tambour” système de freinage. This robust design is the industry standard for heavy-duty drive axles, apprécié pour sa durabilité, couple d'arrêt élevé, and serviceability. Sa fonction première est de convertir l'énergie cinétique du camion de 25 tonnes en chaleur., arrêter le véhicule en toute sécurité. It works by using compressed air to force a set of brake shoes and linings against the inner surface of the rotating brake drum.

Cette déconstruction analysera les principaux assemblages utilisables du Frein de roue central FAW J6P, y compris l'actionneur pneumatique (chambre à air), la liaison mécanique (Came en S et régleur de jeu), les composants de friction (mâchoires et garnitures de frein), et la fondation stationnaire (axle boss). Un bien entretenu Frein de roue central FAW J6P is the most critical safety system on the tandem axles, et son état n'est pas négociable pour un fonctionnement en toute sécurité. Every part of the Frein de roue central FAW J6P must be inspected regularly.

C'est le “muscle” de la Frein de roue central FAW J6P. Ce composant convertit le signal pneumatique de la pédale de frein en une puissante force mécanique.

1. Composant: ‘Center left brake air chamber assy’ (3530020-A0E) & ‘Center right’ (3530025-A0E)

Ce (Comp 32) est la chambre de frein pneumatique complète. C'est un “frein à ressort” ou “piggyback” assemblée. Le Logique pneumatique-mécanique est sa fonction première: lorsque le conducteur appuie sur la pédale de frein, compressed air fills the service chamber, pushing a rod out to apply the brakes.

Le Parking Brake Logic is the second function. A powerful internal spring is held compressed by constant air pressure. When the driver pulls the park brake, this air is released, and the spring mechanically expands, forcing the pushrod out and locking the Frein de roue central FAW J6P. A leaking diaphragm in this chamber is a common failure point and will result in a dangerous air leak and a loss of braking power. Il s'agit d'un élément de sécurité essentiel du Frein de roue central FAW J6P.

Ce groupe de composants constitue la base stationnaire du Frein de roue central FAW J6P. It bolts directly to the axle housing and serves as the anchor point for the brake shoes.

1. Composant: ‘Left axle boss’ (3503127-A0E) – Quantité 1

Ce (Comp 10) est le “araignée” ou “plaque de support”. C'est un énorme, single-piece cast iron component that bolts to the axle. C'est Logique du point d'ancrage est d'absorber tout le couple et les forces générés par l'action de freinage. Les sabots de frein (Comp 18) sont ancrés à cette araignée, et c'est le composant que la S-cam (Comp 3) traverse.

2. Composant: ‘Spacer – axle boss support’ (3502123-A0E) – Quantité 2

Ce (Comp 13) is a precision spacer used to properly position the axle boss on the axle housing, Assurer le Frein de roue central FAW J6P is perfectly aligned with the brake drum.

3. Composant: ‘Rear brake dust pan’ (3502031-A0E) & ‘Front dust pan’ (3502032-A0E)

Ce (Comp 8 & 9) is the dust shield assembly. These thin metal plates bolt to the spider (Comp 10) and partially enclose the Frein de roue central FAW J6P to protect the shoes and drum from contamination by rocks, boue, et débris de la route, which is critical in a dump truck application.

C'est le “porter” une partie du Frein de roue central FAW J6P. Ces composants sont conçus pour être sacrifiés pour créer la friction nécessaire à l'arrêt du camion..

1. Composant: ‘Brake shoe with lining assy’ (3502375-A0E) – Quantité 4

Ce (Comp 18) est la mâchoire de frein complète, qui comprend l'acier “la toile” and the pre-riveted friction lining. Le Frein de roue central FAW J6P utilise deux de ces chaussures (primaire et secondaire) par roue.

2. Composant: ‘Rear brake lining I’ (3502406-A0E) & ‘Rear brake lining II’ (3502407-A0E) – Quantité 4 chaque

Ce (Comp 20, 21) est le matériau de friction utilisable. Le Logique de friction implique deux types de revêtement différents (I et II), ce qui suggère un “début/fin” ou “primaire/secondaire” conception de chaussures. Une doublure est plus agressive pour fournir la morsure initiale, tandis que l'autre est conçu pour une friction et une dissipation thermique soutenues.

3. Composant: 'Rivet – garniture de frein’ (3502408-A0E) – Quantité 112

Ce (Comp 22) est l'ensemble de 112 rivets used to attach the ‘Brake linings’ (Comp 20, 21) to the steel brake shoe web. Cette conception rivetée est courante dans les véhicules lourds Frein de roue central FAW J6P systèmes car il est solide et permet de remplacer les doublures.

4. Composant: « Ressort de retour’ (3502436-A0E) & ‘Anchor pin’ (3502398-A0E)

Ce (Comp 28, 27) is the retraction system. The heavy-duty ‘Return spring’ connects to the ‘Anchor pin’ (Comp 27) and aggressively pulls the brake shoes back away from the brake drum the instant the driver releases the pedal. A weak or broken return spring will cause the Frein de roue central FAW J6P à “traîner,” leading to extreme overheating and failure.

Ce groupe de composants forme le lien mécanique entre la chambre à air (Cœur 1) et les mâchoires de frein (Cœur 3). Il traduit la poussée linéaire de la chambre à air en un mouvement de rotation qui écarte les chaussures.. C'est le cœur du Frein de roue central FAW J6P.

1. Composant: ‘Left/Right slack adjuster assy’ (3503205-A0E, 3503210-A0E) – Quantité 1 chaque

Ce (Comp 14) est le “régleur de jeu”. Ce Logique auto-ajustable est une caractéristique clé d'un Frein de roue central FAW J6P. Comme les garnitures de frein (Comp 20, 21) porter, cet appareil ajuste automatiquement son angle sur l'arbre à cames pour assurer le “mou” (distance) entre le revêtement et le tambour reste minime. Cela fournit une cohérence, pédale de frein réactive.

2. Composant: ‘Left/Right rear brake camshaft’ (3502151-A6E, 3502152-A6E) – Quantité 1 chaque

Ce (Comp 3) est la « S-cam ». Il s'agit d'un arbre en acier forgé avec un “S” tête en forme à une extrémité. En tant que régleur de jeu (Comp 14) fait tourner cet arbre, le “S” la forme pousse contre les « rouleaux de patins de frein’ (Comp 26), forcer les mâchoires de frein à se séparer et à entrer dans le tambour. Il s'agit de la multiplication finale de la force mécanique dans le Frein de roue central FAW J6P.

3. Composant: ‘Camshaft bearing assy’ (3502135-A0E) & ‘Seals’ (3502153-A0E)

Ce (Comp 4, 5, 7) is the bearing and seal system for the camshaft. The camshaft must rotate smoothly within the axle boss (Comp 10). These ‘Bearings’ (Comp 4) and ‘Oil seals’ (Comp 5, 7) ensure a low-friction rotation and prevent water and grit from entering and seizing the Frein de roue central FAW J6P arbre à cames.

Le tableau suivant fournit l'intégralité, ventilation détaillée de tous 32 component groups in the Frein de roue central FAW J6P assemblage pour le FAW Jiefang CA3250P66K2L1T1E 6×4 tombereau. Cette liste est indispensable pour tout service du Frein de roue central FAW J6P.

| Marque | Partie no. | Nom de la pièce | Quantité |

|---|---|---|---|

| – | 3503025-A6E | Center Brake Assy (Self-adjusting, 1830 BM) | 1 |

| 1 | 3502021-A0E | Rear brake assy | 2 |

| CQ70001 | Graisseur de type droit | 2 | |

| Q966555 | Épingle à balle | 2 | |

| 2 | 3502038-487 | Bouchon anti-poussière | 14 |

| 3 | 3502151-A6E / 3502152-A6E | Left/Right rear brake camshaft | 1 chaque |

| 4 | 3502135-A0E | Camshaft bearing assy | 4 |

| 5 | 3502153-A0E | Joint d'huile – camshaft support | 6 |

| 6 | 3502124-A0E | Soutien – Joint Huile | 4 |

| 7 | 3502153-A0E | Joint d'huile – arbre à cames de frein | 4 |

| 8 | 3502031-A0E | Rear brake dust pan | 2 |

| 9 | 3502032-A0E | Rear brake front dust pan | 2 |

| 10 | 3503127-A0E | Bossage d'essieu gauche | 1 |

| 13 | 3502123-A0E | Entretoise – axle boss support | 2 |

| 14 | 3503205-A0E / 3503210-A0E | Left/Right slack adjuster assy | 1 chaque |

| 15 | 3501251-A0S | Entretoise – régleur de jeu | 2 |

| 16 | 3502432-A0E | Oil cup 2 | 2 |

| 17 | 3502431-A0E | Oil cup 1 | 2 |

| 18 | 3502375-A0E | Brake shoe with lining assy | 4 |

| 19 | 3502391-A0E | Rear brake shoe pin | 4 |

| 20 | 3502406-A0E | Rear brake lining I | 4 |

| 21 | 3502407-A0E | Rear brake lining II | 4 |

| 22 | 3502408-A0E | Rivet – garniture de frein | 112 |

| 23 | 3501396-A0S | Bague – front brake shoe | 4 |

| 24 | 3502394A0E | Arbre à rouleaux | 4 |

| 25 | 3502393-A0E | Bushing-roller | 4 |

| 26 | 3502392-A0E | Rouleau | 4 |

| 27 | 3502398-A0E | Goupille d'ancrage à ressort de rappel | 4 |

| 28 | 3502436-A0E | Ressort de rappel | 4 |

| 29 | 3501051-A0S | Cale | 4 |

| 30 | 3501052-A0S | Lock plate – cale | 2 |

| 31 | 3501053-A0S | Goupille de verrouillage – shim lock plate | 2 |

| 32 | 3530020-A0E / 3530025-A0E | Left/Right center brake air chamber assy | 1 chaque |

Les spécifications pour le Frein de roue central FAW J6P sont définis par sa robuste came en S, conception à commande pneumatique, built for the heavy-duty service of a tandem drive axle. Un bien réglé et entretenu Frein de roue central FAW J6P est essentiel pour la sécurité du véhicule.

| Demande de véhicule | FAW Jiefang CA3250P66K2L1T1E 6×4 Tombereau |

| Groupe système | Frein de roue central FAW J6P |

| Type de frein | Frein à tambour à came en S |

| Actionnement | Pneumatique – ‘Brake air chamber assy’ (3530020-A0E) |

| Liaison d'actionnement | ‘Rear brake camshaft’ (3502151-A6E) |

| Ajustement | « Ensemble de régleur de jeu automatique’ (3503205-A0E) |

| Composant de friction | ‘Brake shoe with lining assy’ (3502375-A0E) |

| Matériau de friction | ‘Rear brake lining I’ (3502406-A0E) & ‘II’ (3502407-A0E) | Section 17: ‘Rondelle de blocage – écrou de fusée de direction’ (2)

| Fondation | ‘Left axle boss’ (3503127-A0E) (Brake Spider) |

| Types de composants totaux | 32 |

| Système associé | Center Axle / Système de freinage. Le Frein de roue central FAW J6P est le noyau. |

Pièces FAW, y compris l'ensemble bloc-cylindres, sont emballés avec soin pour garantir une livraison en toute sécurité. Chaque composant est sécurisé dans des matériaux de protection pour éviter tout dommage pendant le transport. Le réseau logistique garantit des expéditions ponctuelles dans le monde entier, soutenir des opérations de maintenance efficaces. Vous trouverez ci-dessous une image illustrant l'emballage standard des pièces de camion FAW., mettant en valeur l’attention portée aux détails dans la manipulation et le stockage.

Cette approche d'emballage minimise le risque de corrosion ou de dommages causés par les chocs., s'assurer que les pièces comme l'ensemble bloc-cylindres FAW arrivent en parfait état. Les clients peuvent compter sur la logistique de FAW pour une qualité et une fiabilité constantes.