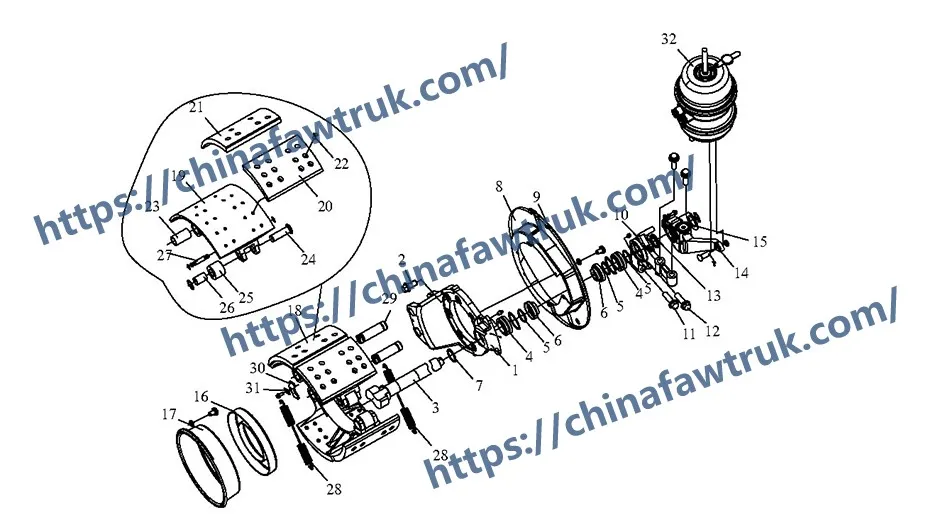

Esta es una guía técnica completa para el Freno de rueda central FAW J6P (Model 3503025-A6E) Para FAW Jiefang CA3250P66K2L1T1E 6×4 camión volcado. Esta deconstrucción analiza la 32 serviceable component types that form the complete S-cam brake assembly for the middle (adelante) drive axle.

El Freno de rueda central FAW J6P es un trabajo pesado, Estafa “tambor” sistema de frenos. Este diseño robusto es el estándar de la industria para ejes motrices de servicio pesado., apreciado por su durabilidad, alto par de parada, y capacidad de servicio. Su función principal es convertir la energía cinética del camión de 25 toneladas en calor., detener el vehículo de forma segura. Funciona mediante el uso de aire comprimido para forzar un conjunto de zapatas y forros de freno contra la superficie interna del tambor de freno giratorio..

Esta deconstrucción analizará los principales conjuntos útiles del Freno de rueda central FAW J6P, incluyendo el actuador neumático (air chamber), el enlace mecanico (Leva S y ajustador de holgura), los componentes de fricción (zapatas y forros de freno), y la base estacionaria (jefe del eje). Un mantenimiento adecuado Freno de rueda central FAW J6P es el sistema de seguridad más crítico en los ejes tándem, y su condición no es negociable para una operación segura. Cada parte del Freno de rueda central FAW J6P debe ser inspeccionado periódicamente.

Este es el “músculo” del Freno de rueda central FAW J6P. This component converts the pneumatic signal from the brake pedal into powerful mechanical force.

1. Componente: ‘Center left brake air chamber assy’ (3530020-A0E) & ‘Center right’ (3530025-A0E)

Este (compensación 32) es la cámara de freno de aire completa. Este es un “freno de resorte” o “a cuestas” asamblea. El Lógica neumática a mecánica es su función principal: cuando el conductor presiona el pedal del freno, El aire comprimido llena la cámara de servicio., empujando una varilla hacia afuera para aplicar los frenos.

El Lógica del freno de estacionamiento is the second function. Un potente resorte interno se mantiene comprimido mediante una presión de aire constante.. Cuando el conductor aplica el freno de estacionamiento, este aire se libera, y el resorte se expande mecánicamente, forzando la varilla de empuje hacia afuera y bloqueando el Freno de rueda central FAW J6P. Un diafragma con fugas en esta cámara es un punto de falla común y resultará en una fuga de aire peligrosa y una pérdida de potencia de frenado.. Este es un componente crítico de seguridad del Freno de rueda central FAW J6P.

Este grupo de componentes forma la base estacionaria del Freno de rueda central FAW J6P. Se atornilla directamente a la carcasa del eje y sirve como punto de anclaje para las zapatas de freno..

1. Componente: 'Jefe del eje izquierdo’ (3503127-A0E) – Cantidad 1

Este (compensación 10) es el “araña” o “placa de respaldo”. es un enorme, Componente de hierro fundido de una sola pieza que se atornilla al eje.. Es Lógica del punto de anclaje es absorber todo el par y las fuerzas generadas por la acción de frenado. las zapatas de freno (compensación 18) están anclados a esta araña, y es el componente que la S-cam (compensación 3) pasa por.

2. Componente: 'Espaciador – soporte del jefe del eje’ (3502123-A0E) – Cantidad 2

Este (compensación 13) Es un espaciador de precisión que se utiliza para colocar correctamente el saliente del eje en la carcasa del eje., asegurando el Freno de rueda central FAW J6P está perfectamente alineado con el tambor de freno.

3. Componente: 'Recogedor de polvo del freno trasero’ (3502031-A0E) & 'Recogedor delantero’ (3502032-A0E)

Este (compensación 8 & 9) es el conjunto del protector contra el polvo. Estas delgadas placas de metal se atornillan a la araña. (compensación 10) y encerrar parcialmente el Freno de rueda central FAW J6P para proteger las zapatas y el tambor de la contaminación por rocas, lodo, y escombros del camino, Lo cual es crítico en una aplicación de camión volquete..

Este es el “tener puesto” parte del Freno de rueda central FAW J6P. Estos componentes están diseñados para sacrificarse y crear la fricción necesaria para detener el camión..

1. Componente: ‘Brake shoe with lining assy’ (3502375-A0E) – Cantidad 4

Este (compensación 18) es la zapata de freno completa, que incluye el acero “web” y el forro de fricción pre-remachado. El Freno de rueda central FAW J6P usa dos de estos zapatos (primaria y secundaria) por rueda.

2. Componente: «Forro del freno trasero I’ (3502406-A0E) & «Forro del freno trasero II’ (3502407-A0E) – Cantidad 4 cada

Este (compensación 20, 21) es el material de fricción útil. El Lógica de fricción Implica dos tipos diferentes de revestimiento. (Yo y II), lo que sugiere un “líder/final” o “primaria/secundaria” shoe design. Un revestimiento es más agresivo para proporcionar la mordida inicial., mientras que el otro está diseñado para una fricción sostenida y una disipación de calor..

3. Componente: 'Remache – guarnición del freno’ (3502408-A0E) – Cantidad 112

Este (compensación 22) es el conjunto de 112 remaches utilizados para fijar los «forros de freno»’ (compensación 20, 21) a la red de zapatas de freno de acero. Este diseño remachado es común en trabajos pesados. Freno de rueda central FAW J6P sistemas ya que es fuerte y permite reemplazar los revestimientos.

4. Componente: 'Regreso primavera’ (3502436-A0E) & 'Pasador de anclaje’ (3502398-A0E)

Este (compensación 28, 27) es el sistema de retraccion. El resistente 'resorte de retorno'’ se conecta al 'pasador de anclaje’ (compensación 27) y aleja agresivamente las zapatas de freno del tambor de freno en el instante en que el conductor suelta el pedal. Un resorte de retorno débil o roto hará que el Freno de rueda central FAW J6P a “arrastrar,” lo que lleva a un sobrecalentamiento extremo y fallas.

Este grupo de componentes forma el vínculo mecánico entre la cámara de aire. (Centro 1) y las zapatas de freno (Centro 3). Traduce el empuje lineal de la cámara de aire en un movimiento giratorio que separa los zapatos.. Este es el corazón del Freno de rueda central FAW J6P.

1. Componente: 'Conjunto de ajustador de holgura izquierdo/derecho’ (3503205-A0E, 3503210-A0E) – Cantidad 1 cada

Este (compensación 14) es el “ajustador de holgura”. Este Lógica autoajustable es una característica clave de un moderno Freno de rueda central FAW J6P. Como las pastillas de freno (compensación 20, 21) tener puesto, Este dispositivo ajusta automáticamente su ángulo en el árbol de levas para garantizar la “flojo” (distancia) entre el revestimiento y el tambor sigue siendo mínimo. Esto proporciona una consistencia, pedal de freno sensible.

2. Componente: 'Árbol de levas del freno trasero izquierdo/derecho’ (3502151-A6E, 3502152-A6E) – Cantidad 1 cada

Este (compensación 3) es la 'cámara S'. Este es un eje de acero forjado con un “S” cabeza en forma en un extremo. Como ajustador de tensión (compensación 14) gira este eje, el “S” La forma empuja contra los rodillos de las zapatas de freno.’ (compensación 26), forzar las zapatas de freno a separarse y entrar en el tambor. Esta es la multiplicación de fuerza mecánica final en el Freno de rueda central FAW J6P.

3. Componente: 'Conjunto de cojinete del árbol de levas’ (3502135-A0E) & 'Sellos’ (3502153-A0E)

Este (compensación 4, 5, 7) es el sistema de cojinete y sello para el árbol de levas. El árbol de levas debe girar suavemente dentro del saliente del eje. (compensación 10). Estos 'rodamientos’ (compensación 4) y 'Retenes de aceite’ (compensación 5, 7) asegurar una rotación de baja fricción y evitar que el agua y la arena entren y se apoderen del Freno de rueda central FAW J6P árbol de levas.

La siguiente tabla proporciona la información completa, desglose detallado de todos 32 grupos de componentes en el Freno de rueda central FAW J6P Montaje para FAW Jiefang CA3250P66K2L1T1E 6×4 camión volcado. Esta lista es imprescindible para cualquier servicio del Freno de rueda central FAW J6P.

| Marca | Número de pieza. | Nombre de la pieza | Cantidad |

|---|---|---|---|

| – | 3503025-A6E | Center Brake Assy (Self-adjusting, 1830 BM) | 1 |

| 1 | 3502021-A0E | Conjunto de freno trasero | 2 |

| CQ70001 | Engrasador tipo recto | 2 | |

| Q966555 | pasador de bola | 2 | |

| 2 | 3502038-487 | Dust plug | 14 |

| 3 | 3502151-A6E / 3502152-A6E | Árbol de levas del freno trasero izquierdo/derecho | 1 cada |

| 4 | 3502135-A0E | Camshaft bearing assy | 4 |

| 5 | 3502153-A0E | Sello de petróleo – soporte del árbol de levas | 6 |

| 6 | 3502124-A0E | Apoyo – sello de aceite | 4 |

| 7 | 3502153-A0E | Sello de petróleo – árbol de levas de freno | 4 |

| 8 | 3502031-A0E | Rear brake dust pan | 2 |

| 9 | 3502032-A0E | Recogedor de polvo delantero del freno trasero | 2 |

| 10 | 3503127-A0E | Left axle boss | 1 |

| 13 | 3502123-A0E | Espaciador – soporte del jefe del eje | 2 |

| 14 | 3503205-A0E / 3503210-A0E | Left/Right slack adjuster assy | 1 cada |

| 15 | 3501251-A0S | Espaciador – ajustador de holgura | 2 |

| 16 | 3502432-A0E | Oil cup 2 | 2 |

| 17 | 3502431-A0E | Oil cup 1 | 2 |

| 18 | 3502375-A0E | Brake shoe with lining assy | 4 |

| 19 | 3502391-A0E | Rear brake shoe pin | 4 |

| 20 | 3502406-A0E | Rear brake lining I | 4 |

| 21 | 3502407-A0E | Rear brake lining II | 4 |

| 22 | 3502408-A0E | Remache – guarnición del freno | 112 |

| 23 | 3501396-A0S | Cojinete – front brake shoe | 4 |

| 24 | 3502394A0E | Rollero | 4 |

| 25 | 3502393-A0E | Rodillo de casquillo | 4 |

| 26 | 3502392-A0E | Rodillo | 4 |

| 27 | 3502398-A0E | Pasador de anclaje del resorte de retorno | 4 |

| 28 | 3502436-A0E | resorte de retorno | 4 |

| 29 | 3501051-A0S | Calce | 4 |

| 30 | 3501052-A0S | Placa de bloqueo – calce | 2 |

| 31 | 3501053-A0S | Lock pin – shim lock plate | 2 |

| 32 | 3530020-A0E / 3530025-A0E | Left/Right center brake air chamber assy | 1 cada |

Las especificaciones para el Freno de rueda central FAW J6P se definen por su robusta S-cam, diseño accionado por aire, construido para el servicio pesado de un eje motriz tándem. Un equipo correctamente ajustado y mantenido. Freno de rueda central FAW J6P es esencial para la seguridad del vehículo.

| Solicitud de vehículo | FAW Jiefang CA3250P66K2L1T1E 6×4 Camión de la basura |

| Grupo de sistema | Freno de rueda central FAW J6P |

| Tipo de freno | Freno de tambor con leva S |

| Actuación | Neumático – ‘Brake air chamber assy’ (3530020-A0E) |

| Enlace de actuación | «Árbol de levas del freno trasero’ (3502151-A6E) |

| Ajuste | 'Conjunto de ajustador de holgura automático’ (3503205-A0E) |

| Componente de fricción | ‘Brake shoe with lining assy’ (3502375-A0E) |

| Material de fricción | «Forro del freno trasero I’ (3502406-A0E) & 'II’ (3502407-A0E) | Section 17: ‘Lock washer – tuerca del eje del muñón de dirección’ (2)

| Base | 'Jefe del eje izquierdo’ (3503127-A0E) (Brake Spider) |

| Tipos de componentes totales | 32 |

| Sistema asociado | Center Axle / Sistema de frenado. El Freno de rueda central FAW J6P es el núcleo. |

piezas FAW, incluido el conjunto del bloque de cilindros, Se empaquetan con cuidado para garantizar una entrega segura.. Cada componente está asegurado con materiales protectores para evitar daños durante el transporte.. La red logística garantiza envíos puntuales en todo el mundo., apoyando operaciones de mantenimiento eficientes. A continuación se muestra una imagen que ilustra el embalaje estándar de las piezas de camiones FAW., mostrando la atención al detalle en el manejo y almacenamiento.

Este enfoque de embalaje minimiza el riesgo de corrosión o daños por impacto., asegurando que piezas como el conjunto de bloque de cilindros FAW lleguen en perfectas condiciones. Los clientes pueden confiar en la logística de FAW para obtener calidad y confiabilidad constantes.