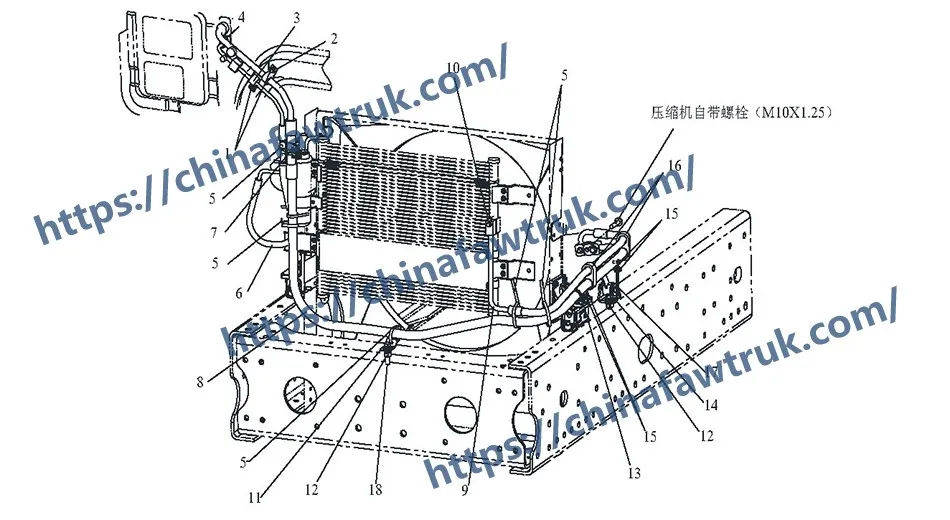

Bienvenue dans cette analyse complète de Cathéter d'administration de fluorure FAW J6P (Tuyau réfrigérant A/C) système pour le FAW Jiefang CA3250P66K2L1T1E 6×4 tombereau. Ceci est le réseau complet de plomberie pour la climatisation. Ce guide détaille les 18 pièces critiques qui forment les conduites de réfrigérant haute et basse pression.

Le Cathéter d'administration de fluorure FAW J6P Le système est l'ensemble de tuyaux flexibles qui relient tous les principaux composants de climatisation.: le compresseur, le condenseur, et l'évaporateur. Ce ne sont pas de simples tubes; ils sont multicouches, tuyaux de type barrière conçus pour supporter des pressions extrêmes (jusqu'à 350+ psi) et empêcher le réfrigérant de s'échapper.

Ce démontage analysera les trois principales conduites de réfrigérant: la haute pression “décharge” doubler, la haute pression “liquide” doubler, et la basse pression “succion” doubler. Nous examinerons également le réseau de supports et de pinces qui sécurisent ce Cathéter d'administration de fluorure FAW J6P système.

Pour un technicien, une fuite dans le Cathéter d'administration de fluorure FAW J6P est un échec courant et critique. Ces fuites, souvent causé par des frottements induits par les vibrations, sont les #1 cause de la panne du système de climatisation. Comprendre le routage et le serrage corrects est essentiel pour une réparation fiable de la climatisation..

Ce groupe contient les trois principaux “plomberie” lignes du Cathéter d'administration de fluorure FAW J6P système, qui sont responsables du transport du réfrigérant.

1. Composant: « Ensemble de tuyaux flexibles à haute pression – Compresseur au condenseur’ (8108080-14B-C00) – Quantité 1

Ce (Marque 9) est le “conduite de décharge.” Il fait chaud, gaz haute pression du compresseur au condenseur. Il doit résister aux températures et pressions les plus élevées du système.

2. Composant: « Ensemble de tuyaux flexibles à haute pression – Condenseur à évaporateur’ (8108130-71U-C00) – Quantité 1

Ce (Marque 6) est le “conduite de liquide.” Il porte refroidi, liquide haute pression du condenseur/sécheur vers le détendeur de la cabine. Son petit diamètre est essentiel pour maintenir la pression du liquide.

3. Composant: « Ensemble de tuyaux flexibles basse pression – Évaporateur à compresseur’ (8108060-14B-C00) – Quantité 1

Ce (Marque 8) est le “conduite d'aspiration.” C'est le tuyau de plus grand diamètre et il transporte le froid, gaz basse pression de l'évaporateur vers le compresseur pour être remis sous pression.

Le “Tuyau de barrière” Logique: Tous les trois Cathéter d'administration de fluorure FAW J6P les durites sont avancées “barrière” tuyaux. Ils ont une doublure intérieure en nylon pour empêcher les minuscules molécules de réfrigérant R134a de pénétrer à travers le caoutchouc., une tresse textile pour le maintien de la pression, et un revêtement extérieur en caoutchouc EPDM pour résister à la chaleur et à l'abrasion du moteur.

Le “Ondulation & Formulaire” Logique: Chaque tuyau est un « Assy »’ car il est serti en permanence sur des tubes en aluminium courbés avec précision. Ces tubes créent les angles exacts nécessaires pour se connecter aux composants sans plier le tuyau.. Une fuite dans le Cathéter d'administration de fluorure FAW J6P est souvent au niveau de ces points de sertissage ou de frottements.

Ce groupe de matériel est tout aussi important que les tuyaux. Sa seule fonction est de sécuriser Cathéter d'administration de fluorure FAW J6P système et empêcher tout mouvement.

1. Composant: 'Support’ (8116121-22U) – Quantité 1

2. Composant: 'Support en forme de L B Assy’ (8108160-70U) – Quantité 1

3. Composant: 'Ensemble de support en forme de L’ (8108150-70U) – Quantité 1

Ces (Marque 11, 13, 17) sont les principaux supports en acier de construction. Ce sont les points d’ancrage fixes qui se boulonnent au moteur ou au châssis du camion, fournissant un emplacement de montage sécurisé pour les pinces.

4. Composant: 'Ensemble de serrage E’ / 'Ensemble de serrage A’ / 'Ensemble de serrage’ (8108075-50UN / 8108065-50UN / 8108095-70U)

Ces (Marque 2, 3, 16) sont les spécialisés, isolé en caoutchouc “Pinces en C” qui entoure les tuyaux. Ils se boulonnent aux supports (Par exemple, Marque 11) et maintenez fermement les tuyaux.

5. Composant: « Sangle en plastique’ (T67427946) – Quantité 5

Ces (Marque 5) sont des attaches en nylon haute température utilisées pour fixer les tuyaux ensemble ou loin des surfaces chaudes.

Le “Anti-frottement” Logique: C’est la logique la plus importante pour l’ensemble Cathéter d'administration de fluorure FAW J6P. Le moteur diesel vibre constamment. Si les tuyaux ne sont pas 100% fixé par ces pinces et supports, ils *vont* frotter (“irriter”) contre le moteur ou le châssis. Ce frottement finira par créer un trou d'épingle dans le tuyau, provoquant une fuite de réfrigérant. Ces parenthèses sont les “anti-fuite” système.

La logique de service: Un technicien *doit* réinstaller chaque pince, support, et sangle lors du remplacement d'un tuyau. Ne pas le faire garantit que le nouveau Cathéter d'administration de fluorure FAW J6P le tuyau tombera en panne prématurément à cause du frottement.

Ce groupe contient tous les différents boulons et écrous utilisés pour assembler le Cathéter d'administration de fluorure FAW J6Ple système de montage.

1. Composant: « Boulon combiné’ (CQ1460612, CQ1460625, CQ1460630, CQ1460635, CQ1461230, CQ1460616, CQ1461235)

Ces (Marque 1, 4, 7, 10, 14, 15, 18) sont tous des « boulons combinés ». Cela signifie qu'ils ont préinstallé, rondelles captives. Il s'agit d'une fonction d'efficacité et d'anti-vibration de la chaîne de montage. Il garantit qu'une rondelle de blocage est utilisée sur chaque connexion pour éviter le desserrage.

Le “Taille différente” Logique: La liste des pièces précise 7 différents numéros de pièces pour ces boulons. C'est intentionnel. Chaque boulon a une longueur et un diamètre précis (Par exemple, M6, M12) requis pour son emplacement spécifique. Un technicien ne peut pas les mélanger. L'utilisation d'un boulon de mauvaise taille entraînera un ajustement lâche ou dénudera les filetages..

2. Composant: «Écrou hexagonal’ (CQ34012) – Quantité 2

Ce (Marque 12) L'écrou hexagonal M12 est utilisé pour fixer le « support’ (Marque 11) à un étalon.

La logique de service (Matériel): Un technicien doit pratiquer l'extrême “discipline matérielle” lors de l'entretien du Cathéter d'administration de fluorure FAW J6P. Tous les boulons, des noisettes, et les pinces doivent être conservées, identifié, et réinstallés dans leurs emplacements d'origine exacts pour éviter les vibrations, friction, et des fuites.

Le tableau suivant fournit l'intégralité, ventilation détaillée de tous 18 types de composants spécifiés pour le Cathéter d'administration de fluorure FAW J6P système sur le FAW Jiefang CA3250P66K2L1T1E 6×4 tombereau.

| Marque | Partie no. | Nom de la pièce | Quantité |

|---|---|---|---|

| 1 | CQ1460612 | Boulon combiné | 2 |

| 2 | 8108075-50UN | Ensemble de serrage E | 1 |

| 3 | 8108065-50UN | Ensemble de serrage A | 1 |

| 4 | CQ1460625 | Boulon combiné | 2 |

| 5 | T67427946 | Sangle en plastique | 5 |

| 6 | 8108130-71U-C00 | Ensemble de tuyaux flexibles haute pression – Condenseur à évaporateur | 1 |

| 7 | CQ1460630 | Boulon combiné | 1 |

| 8 | 8108060-14B-C00 | Ensemble de tuyaux flexibles basse pression – Évaporateur à compresseur | 1 |

| 9 | 8108080-14B-C00 | Ensemble de tuyaux flexibles haute pression – Compresseur au condenseur | 1 |

| 10 | CQ1460635 | Boulon combiné | 1 |

| 11 | 8116121-22U | Support | 1 |

| 12 | CQ34012 | Écrou hexagonal | 2 |

| 13 | 8108160-70U | Support en forme de L, ensemble B | 1 |

| 14 | CQ1461230 | Boulon combiné | 1 |

| 15 | CQ1460616 | Boulon combiné | 4 |

| 16 | 8108095-70U | Ensemble de serrage – Pour la fixation du tuyau de climatisation | 2 |

| 17 | 8108150-70U | Ensemble de support en forme de L | 1 |

| 18 | CQ1461235 | Boulon combiné | 1 |

Les spécifications pour le Cathéter d'administration de fluorure FAW J6P système sont définis par son rôle de système à haute pression, réseau de transport de réfrigérant multicouche.

| Demande de véhicule | FAW Jiefang CA3250P66K2L1T1E 6×4 Tombereau |

| Groupe système | Cathéter d'administration de fluorure FAW J6P (Tuyaux de climatisation) |

| Construction du tuyau | Tuyau de barrière multicouche (EPDM, Nylon, Tresser) |

| Tuyau 1 (Haute pression) | 'Compresseur à condenseur’ (8108080-14B-C00) |

| Tuyau 2 (Haute pression) | « Condenseur à évaporateur’ (8108130-71U-C00) |

| Tuyau 3 (Basse pression) | « De l'évaporateur au compresseur’ (8108060-14B-C00) |

| Raccords d'extrémité | Tubes en aluminium formés avec raccords à joint torique |

| Méthode de scellement | Sertissages hydrauliques haute pression |

| Système de montage | Supports en acier, Pinces isolées en caoutchouc, Sangles en plastique |

| Matériel | Plusieurs « boulons combinés’ et noix |

| Mode de défaillance principal | Frottement induit par les vibrations (Frottement) Fuites |

Pièces FAW, y compris l'ensemble bloc-cylindres, sont emballés avec soin pour garantir une livraison en toute sécurité. Chaque composant est sécurisé dans des matériaux de protection pour éviter tout dommage pendant le transport. Le réseau logistique garantit des expéditions ponctuelles dans le monde entier, soutenir des opérations de maintenance efficaces. Vous trouverez ci-dessous une image illustrant l'emballage standard des pièces de camion FAW., mettant en valeur l’attention portée aux détails dans la manipulation et le stockage.

Cette approche d'emballage minimise le risque de corrosion ou de dommages causés par les chocs., s'assurer que les pièces comme l'ensemble bloc-cylindres FAW arrivent en parfait état. Les clients peuvent compter sur la logistique de FAW pour une qualité et une fiabilité constantes.