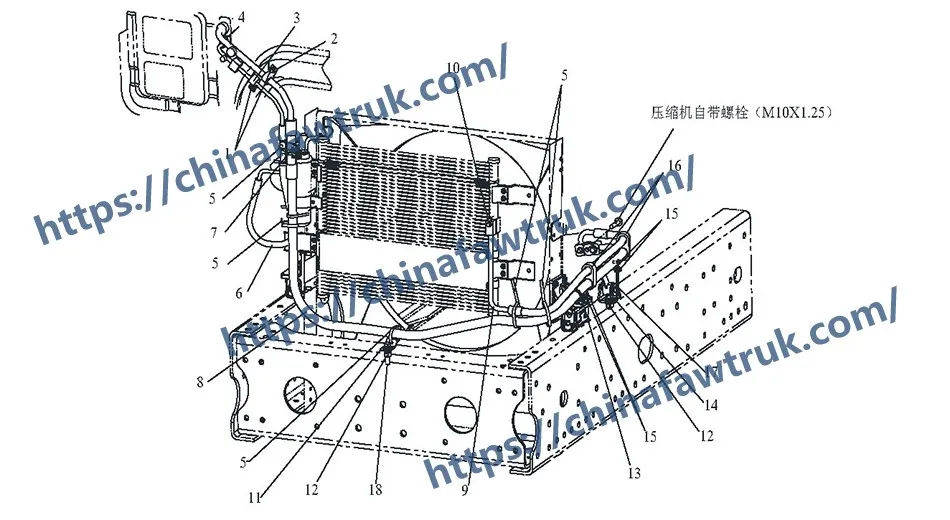

Welcome to this complete analysis of the FAW J6P Fluoride Delivery Catheter (A/C Refrigerant Hose) system for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck. This is the complete plumbing network for the A/C. This guide details the 18 critical parts that form the high and low-pressure refrigerant lines.

The FAW J6P Fluoride Delivery Catheter system is the set of flexible hoses that connect all the main A/C components: the compressor, the condenser, and the evaporator. These are not simple tubes; they are multi-layer, barrier-style hoses designed to handle extreme pressure (up to 350+ PSI) and prevent refrigerant from escaping.

This teardown will analyze the three main refrigerant lines: the high-pressure “discharge” line, the high-pressure “liquid” line, and the low-pressure “suction” line. We will also examine the network of brackets and clamps that secure this FAW J6P Fluoride Delivery Catheter system.

For a technician, a leak in the FAW J6P Fluoride Delivery Catheter is a common and critical failure. These leaks, often caused by vibration-induced chafing, are the #1 cause of A/C system failure. Understanding the correct routing and clamping is essential for a reliable A/C repair.

This group contains the three main “plumbing” lines of the FAW J6P Fluoride Delivery Catheter system, which are responsible for transporting the refrigerant.

1. Component: ‘Flexible High-Pressure Pipe Assy – Compressor to Condenser’ (8108080-14B-C00) – Qty 1

This (Mark 9) is the “discharge line.” It carries hot, high-pressure gas from the compressor to the condenser. It must withstand the highest temperatures and pressures in the system.

2. Component: ‘Flexible High-Pressure Pipe Assy – Condenser to Evaporator’ (8108130-71U-C00) – Qty 1

This (Mark 6) is the “liquid line.” It carries cooled, high-pressure liquid from the condenser/drier to the cab’s expansion valve. Its small diameter is essential for maintaining liquid pressure.

3. Component: ‘Flexible Low-Pressure Pipe Assy – Evaporator to Compressor’ (8108060-14B-C00) – Qty 1

This (Mark 8) is the “suction line.” It is the largest-diameter hose and carries cold, low-pressure gas from the evaporator back to the compressor to be re-pressurized.

The “Barrier Hose” Logic: All three of these FAW J6P Fluoride Delivery Catheter hoses are advanced “barrier” hoses. They have an inner Nylon lining to prevent the tiny R134a refrigerant molecules from permeating through the rubber, a textile braid for pressure-holding, and an outer EPDM rubber cover to resist engine heat and abrasion.

The “Crimp & Form” Logic: Each hose is an ‘Assy’ because it is permanently crimped to precision-bent aluminum tubes. These tubes create the exact angles needed to connect to the components without kinking the hose. A leak in the FAW J6P Fluoride Delivery Catheter is often at these crimp points or from chafing.

This group of hardware is just as important as the hoses. Its sole function is to secure the FAW J6P Fluoride Delivery Catheter system and prevent movement.

1. Component: ‘Bracket’ (8116121-22U) – Qty 1

2. Component: ‘L-Shaped Bracket B Assy’ (8108160-70U) – Qty 1

3. Component: ‘L-Shaped Bracket Assy’ (8108150-70U) – Qty 1

These (Mark 11, 13, 17) are the main structural steel brackets. They are the fixed anchor points that bolt to the truck’s engine or chassis, providing a secure mounting location for the clamps.

4. Component: ‘Clamp Assy E’ / ‘Clamp Assy A’ / ‘Clamp Assy’ (8108075-50A / 8108065-50A / 8108095-70U)

These (Mark 2, 3, 16) are the specialized, rubber-isolated “C-clamps” that wrap around the hoses. They bolt to the brackets (e.g., Mark 11) and securely hold the hoses.

5. Component: ‘Plastic Strap’ (T67427946) – Qty 5

These (Mark 5) are high-temperature Nylon zip-ties used to secure hoses together or away from hot surfaces.

The “Anti-Chafe” Logic: This is the single most important logic for the entire FAW J6P Fluoride Delivery Catheter. The diesel engine vibrates constantly. If the hoses are not 100% secured by these clamps and brackets, they *will* rub (“chafe”) against the engine or frame. This rubbing will eventually saw a pinhole in the hose, causing a refrigerant leak. These brackets are the “anti-leak” system.

The Service Logic: A technician *must* reinstall every single clamp, bracket, and strap when replacing a hose. Failing to do so guarantees that the new FAW J6P Fluoride Delivery Catheter hose will fail prematurely from chafing.

This group contains all the various bolts and nuts used to assemble the FAW J6P Fluoride Delivery Catheter‘s mounting system.

1. Component: ‘Combination Bolt’ (CQ1460612, CQ1460625, CQ1460630, CQ1460635, CQ1461230, CQ1460616, CQ1461235)

These (Mark 1, 4, 7, 10, 14, 15, 18) are all ‘Combination Bolts’. This means they have pre-installed, captive washers. This is an assembly-line efficiency and anti-vibration feature. It guarantees a lock washer is used on every connection to prevent loosening.

The “Different Size” Logic: The parts list specifies 7 different part numbers for these bolts. This is intentional. Each bolt has a precise length and diameter (e.g., M6, M12) required for its specific location. A technician cannot mix these up. Using the wrong size bolt will cause a loose fit or strip the threads.

2. Component: ‘Hex Nut’ (CQ34012) – Qty 2

This (Mark 12) M12 hex nut is used to secure the ‘Bracket’ (Mark 11) to a stud.

The Service Logic (Hardware): A technician must practice extreme “hardware discipline” when servicing the FAW J6P Fluoride Delivery Catheter. All bolts, nuts, and clamps must be saved, identified, and re-installed in their exact original locations to prevent vibration, chafing, and leaks.

The following table provides the complete, detailed breakdown of all 18 component types specified for the FAW J6P Fluoride Delivery Catheter system on the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | CQ1460612 | Combination Bolt | 2 |

| 2 | 8108075-50A | Clamp Assy E | 1 |

| 3 | 8108065-50A | Clamp Assy A | 1 |

| 4 | CQ1460625 | Combination Bolt | 2 |

| 5 | T67427946 | Plastic Strap | 5 |

| 6 | 8108130-71U-C00 | Flexible High-Pressure Pipe Assy – Condenser to Evaporator | 1 |

| 7 | CQ1460630 | Combination Bolt | 1 |

| 8 | 8108060-14B-C00 | Flexible Low-Pressure Pipe Assy – Evaporator to Compressor | 1 |

| 9 | 8108080-14B-C00 | Flexible High-Pressure Pipe Assy – Compressor to Condenser | 1 |

| 10 | CQ1460635 | Combination Bolt | 1 |

| 11 | 8116121-22U | Bracket | 1 |

| 12 | CQ34012 | Hex Nut | 2 |

| 13 | 8108160-70U | L-Shaped Bracket B Assy | 1 |

| 14 | CQ1461230 | Combination Bolt | 1 |

| 15 | CQ1460616 | Combination Bolt | 4 |

| 16 | 8108095-70U | Clamp Assy – For Fastening A/C Pipe | 2 |

| 17 | 8108150-70U | L-Shaped Bracket Assy | 1 |

| 18 | CQ1461235 | Combination Bolt | 1 |

The specifications for the FAW J6P Fluoride Delivery Catheter system are defined by its role as a high-pressure, multi-layer refrigerant transport network.

| Vehicle Application | FAW Jiefang CA3250P66K2L1T1E 6×4 Dump Truck |

| System Group | FAW J6P Fluoride Delivery Catheter (A/C Hoses) |

| Hose Construction | Multi-Layer Barrier Hose (EPDM, Nylon, Braid) |

| Hose 1 (High Pressure) | ‘Compressor to Condenser’ (8108080-14B-C00) |

| Hose 2 (High Pressure) | ‘Condenser to Evaporator’ (8108130-71U-C00) |

| Hose 3 (Low Pressure) | ‘Evaporator to Compressor’ (8108060-14B-C00) |

| End Fittings | Formed Aluminum Tubes with O-Ring Fittings |

| Sealing Method | High-Pressure Hydraulic Crimps |

| Mounting System | Steel Brackets, Rubber-Isolated Clamps, Plastic Straps |

| Hardware | Multiple ‘Combination Bolts’ and Nuts |

| Primary Failure Mode | Vibration-Induced Chafing (Rubbing) Leaks |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.