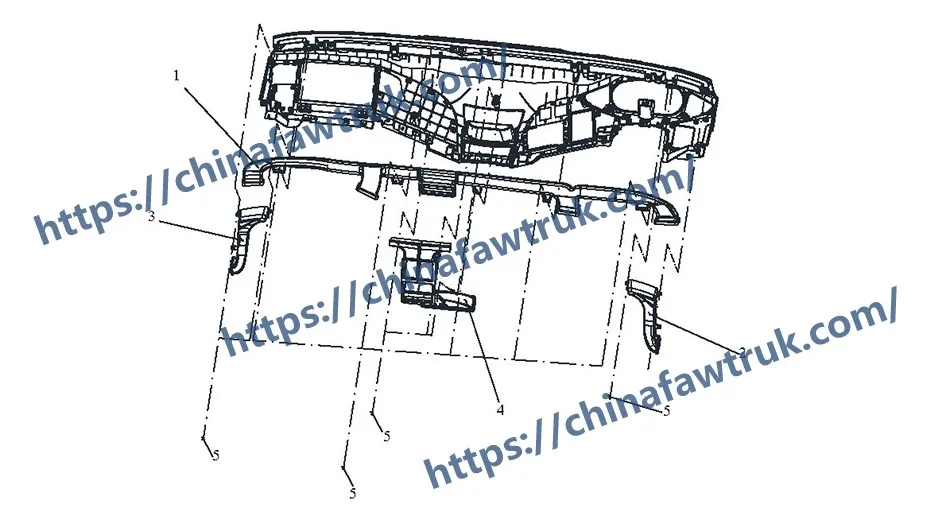

Welcome to this detailed examination of the FAW J6P Air Duct system for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck. This is the complete air distribution network for the cab’s climate control. This guide examines the 5 critical component types that ensure efficient heating, cooling, and defrosting.

The FAW J6P Air Duct system is a complex, hidden network of molded polymer channels. It is the vital “delivery” system that takes the conditioned air from the main HVAC “Two-Box” assembly and transports it silently and efficiently to the correct vents: the face, the feet, and the windscreen.

This teardown will analyze all four main duct assemblies and their critical fasteners. For a CA3250P66K2L1T1E dump truck, this system’s performance is not a luxury. The defrost function is a primary safety system for visibility, and the system’s acoustic design is a key part of controlling Noise, Vibration, and Harshness (NVH) in the cab.

We will explore the logic of each duct’s “Assy” (Assembly) designation, focusing on the integrated foam seals that prevent leaks and rattles. A failing FAW J6P Air Duct (cracked, loose, or with bad seals) is a primary cause of “poor A/C performance,” “no heat to feet,” or “whistling” noises from the dash.

This group contains the primary ducts for driver and passenger comfort, distributing air to the main dashboard vents.

1. Component: ‘Face Air Duct Assy’ (8102010-B27-C00) – Qty 1

This (Mark 1) is the main “face-level” duct. It is a wide, horizontal plenum that runs behind the center dashboard and branches off to the two central vents and the driver’s-side face vent.

The Plenum Logic: This component of the FAW J6P Air Duct is designed as a plenum. This means its large internal volume allows air pressure to equalize, ensuring that the same volume and velocity of air comes out of all the connected vents. A poorly designed duct would send all the air to the closest vent, “starving” the others.

2. Component: ‘Center Transition Air Duct Assy’ (8102050-B27-C00) – Qty 1

This (Mark 4) is the “main artery” of the FAW J6P Air Duct system. It is the first piece in the chain, connecting the main outlet of the HVAC “Two-Box” assembly to the inlet of the ‘Face Air Duct’ (Mark 1) and other ducts.

The “Serpentine” Logic: This duct has a highly complex, “serpentine” shape. It must be molded to navigate the tight, crowded space behind the dash, routing around the steering column, wiring harnesses, and dashboard support beams. Its shape is critical for a precise, factory fit.

This pair of components is a primary safety feature of the FAW J6P Air Duct system. Their sole function is to ensure the driver’s side-view mirrors are always visible.

1. Component: ‘Left Side Door Defrost Transition Duct Assy’ (8102065-B27-C00) – Qty 1

This (Mark 2) is the dedicated duct for the driver’s side. It taps into the main HVAC plenum and channels a high-velocity stream of dry, hot air directly to the small vent aimed at the driver’s side door window.

2. Component: ‘Right Side Door Defrost Transition Duct Assy’ (8102070-B27-C00) – Qty 1

This (Mark 3) is the identical, mirrored component for the passenger’s side door.

The “Mirror Visibility” Logic: In a heavy truck, the side-view mirrors are the *only* way to see the sides and rear of the vehicle. In cold or rainy weather, the side windows fog or ice over, rendering these mirrors completely useless. This FAW J6P Air Duct component is a safety-critical system that blasts air to keep this small patch of glass clear, ensuring the driver can *always* see their mirrors.

The “Transition” Logic: The name “Transition Duct” (过渡风管) means it acts as a bridge. It connects the main, rigid plenum to the final vent, which is often integrated into the dashboard’s soft-touch “A-pillar” trim. Its shape is complex to fit inside this narrow pillar.

This logic applies to all four duct components (Mark 1-4). The “Assy” (总成) designation in their names is critical, as it implies they are not just bare plastic, but come with pre-installed, non-serviceable seals.

The Sealing Logic: Every connection point on the FAW J6P Air Duct (e.g., where the ‘Center Duct’ meets the ‘Face Duct’, or where the ‘Face Duct’ meets the dash vent) is sealed with a gasket. This is typically a die-cut, high-density polyurethane foam or EPDM rubber gasket.

The “Air Leak” Logic: This seal is the key to performance. Without it, high-pressure conditioned air would leak from every joint, “bleeding” into the dashboard. This would result in a massive loss of pressure, causing weak airflow at the vents. The driver would complain of “no A/C” or “no heat” simply because the air is not reaching its destination. These seals make the FAW J6P Air Duct an efficient, closed-loop system.

The “NVH” Logic (Noise, Vibration, Harshness): These foam seals serve a second, vital purpose: they are anti-rattle pads. The FAW J6P Air Duct system is a large network of hard plastic, mounted against a hard plastic/metal dashboard frame. In a dump truck, these hard surfaces would vibrate against each other, creating an unacceptable symphony of squeaks, buzzes, and rattles.

The Service Logic (Gasket): The gaskets are pre-applied at the factory with a high-strength adhesive. They are not available as a separate part. If a technician removes a duct and the foam gasket is compressed, torn, or has crumbled from age, the *entire duct assembly* must be replaced to guarantee a quiet, leak-free repair.

This component is the “glue” that holds the entire FAW J6P Air Duct system together, ensuring a rigid, vibration-free installation.

1. Component: ‘Cross recessed pan head tapping screw and plain washer assembly’ (CQ2214126F6) – Qty 15

This (Mark 5) is the set of 15 identical, specialized fasteners used to secure all the duct components (Core 1-3) to each other and to the main dashboard structure.

The “Tapping Screw” Logic: These are “self-tapping” (自攻螺钉). Their threads are hardened and sharp, designed to cut their own mating threads as they are screwed into the soft, plastic “bosses” of the dashboard and duct assemblies. This is a fast and secure assembly method.

The “Combination” Logic: The name “assembly” (组合件) is critical. It means each screw has a pre-installed, “captive” plain washer (平垫圈). This washer is not for locking; it is for *load distribution*.

The “Anti-Crack” Logic: The washer’s job is to spread the clamping force of the screw head over a wide area of the plastic mounting tab. Without this washer, the small screw head would create a point of high stress, cracking the plastic tab. This washer is essential for the long-term durability of the FAW J6P Air Duct.

The Service Logic (Fasteners): The high quantity (15) is necessary to firmly secure the entire network and prevent any movement. A single loose screw in this FAW J6P Air Duct system will result in a hard-to-find, annoying “buzz” or “rattle” that the driver will hear on every bump. A technician must check all 15 fasteners when diagnosing a dashboard rattle.

The following table provides the complete, detailed breakdown of all 5 component types specified for the FAW J6P Air Duct system on the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 8102010-B27-C00 | Face Air Duct Assy | 1 |

| 2 | 8102065-B27-C00 | Left Side Door Defrost Transition Duct Assy | 1 |

| 3 | 8102070-B27-C00 | Right Side Door Defrost Transition Duct Assy | 1 |

| 4 | 8102050-B27-C00 | Center Transition Air Duct Assy | 1 |

| 5 | CQ2214126F6 | Cross recessed pan head tapping screw and plain washer assembly | 15 |

The specifications for the FAW J6P Air Duct system are defined by its function as a sealed, quiet, and efficient air delivery network.

| Vehicle Application | FAW Jiefang CA3250P66K2L1T1E 6×4 Dump Truck |

| System Group | FAW J6P Air Duct |

| Duct Material | Injection-Molded Polymer (e.g., Polypropylene, PC-ABS) |

| Function 1 | Comfort (Heating/Cooling) Air Distribution |

| Function 2 | Safety (Windscreen & Side Door Defrost) |

| Function 3 | NVH Control (Noise/Vibration Prevention) |

| Sealing Mechanism | Pre-installed Foam or EPDM Gaskets (as ‘Assy’) |

| Fastener Type | Self-Tapping Combination Screw (with Plain Washer) |

| Fastener Part No. | CQ2214126F6 |

| Fastener Quantity | 15 |

| Associated System | HVAC “Two-Box” Unit (8100015-B27-C00) |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.