Welcome to this critical analysis of the FAW J6P External Air Filter system for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck. This is the first line of defense for the cab’s HVAC system and the driver’s health. This guide analyzes the 5 key components that create this vital filtration system.

The FAW J6P External Air Filter, also known as the cabin air filter, is a non-negotiable component for a heavy-duty dump truck. Operating in the extreme dust of quarries, construction sites, and unpaved roads, the CA3250P66K2L1T1E is constantly exposed to airborne silica, pollen, soot, and debris.

This filter’s job is twofold: first, it protects the driver’s respiratory health by providing clean, breathable air. Second, it protects the HVAC system itself. Without this FAW J6P External Air Filter, the evaporator core would become clogged with a “blanket” of dust, destroying its ability to cool the cab.

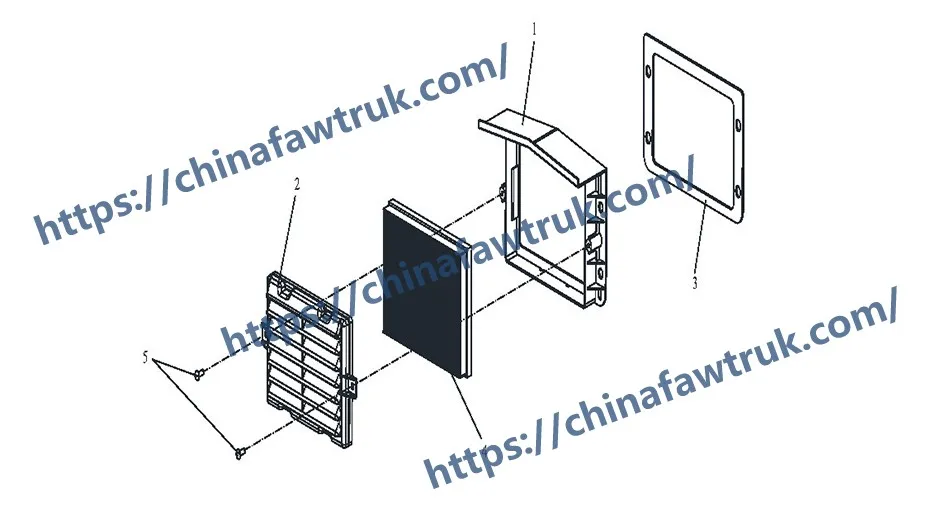

This deconstruction will analyze the full assembly, including the two-piece housing, the all-important filter element, the rubber gasket, and the mounting hardware. For a technician, a clogged or missing FAW J6P External Air Filter is the number one cause of all “low airflow” or “poor A/C” complaints.

This is the functional heart of the FAW J6P External Air Filter. It is the single, replaceable component that does all the work.

1. Component: ‘Filter Element-External Air Filter’ (8101574-A01) – Qty 1

This (Mark 4) is the filter element, or “cartridge.” It is a high-efficiency, pleated-media filter designed for a high-dust environment.

The Media Logic: This is not paper. The filter media is a synthetic, non-woven, electrostatically-charged material. The “non-woven” design creates a complex, three-dimensional web of fibers that traps particles of different sizes. The “electrostatic charge” acts like a magnet, actively pulling and holding microscopic particles (like dust and pollen) that would otherwise pass right through.

The Pleating Logic: The media is heavily “pleated” (folded) to maximize its surface area within a small box. This is critical. A high surface area allows the FAW J6P External Air Filter to hold a massive amount of dust before it becomes restrictive, extending its service life.

The Activated Charcoal Logic: Many high-end filters, especially for the FAW J6P External Air Filter, are “combination filters.” They embed a layer of activated charcoal into the media. This charcoal’s function is to absorb odors, such as diesel fumes, exhaust gases (NOx, SOx), and other chemical smells from the job site, preventing them from entering the cab.

The System Protection Logic: The #1 enemy of an A/C system is dust. This filter element is the only thing protecting the evaporator core. Without it, the evaporator’s fine aluminum fins become clogged with a thick, wet mat of dust. This blocks all airflow, causing the driver to complain of “no A/C” or “no heat.” The evaporator ices over, and the backed-up condensation can flood the cab floor.

The Service Logic: This is a primary, mandatory service item. For a dump truck, this filter may need to be replaced every 5,000 miles (or even more frequently) in severe dust. A clogged FAW J6P External Air Filter is the most common, and cheapest, fix for a poor-performing HVAC system.

This is the two-piece, protective “shell” that holds the filter element (Core 1) and seals it against the truck’s body.

1. Component: ‘Box A-External Air Filter’ (8101571-B27) – Qty 1

This (Mark 1) is the main body or base of the FAW J6P External Air Filter housing. It is the part that bolts to the cab’s air intake plenum.

2. Component: ‘Box B-External Air Filter’ (8101572-A01) – Qty 1

This (Mark 2) is the removable “cover” or “lid” of the housing. It is the part the technician removes to access and replace the filter element.

The Two-Piece Logic: This “clamshell” design is purely for service. The Box A (base) is semi-permanently mounted to the truck. The Box B (cover) is designed for quick removal, held on by clips or the two tapping screws (Core 4). This provides fast, “no-tools” access to the filter element.

The Material Logic: Both housing pieces are injection-molded from a durable, high-temperature, and impact-resistant polymer (like glass-filled Polypropylene). This material is chosen because it is lightweight, corrosion-proof, and inexpensive to manufacture in complex shapes. It must be strong enough to resist cracking from vibration or minor impacts.

The Water Drainage Logic: This is a critical design feature. The FAW J6P External Air Filter is located in the fresh-air plenum, which is exposed to rain and snow. The housing (Box A) is designed with a “water-shedding” shape and has built-in drain holes. This allows any ingested water to drain out *before* it can soak the filter element. A water-soaked filter blocks all airflow and will grow mold.

This group contains the components that ensure a perfect, airtight seal. An unsealed filter is a useless filter.

1. Component: ‘Rubber Gasket-External Air Filter’ (8101573-A01) – Qty 1

This (Mark 3) is a precision-molded rubber gasket. It is the most critical part of the FAW J6P External Air Filter housing.

The Sealing Logic: This gasket creates the airtight seal between the Box A (base) and the Box B (cover). It is designed to be compressed by the two tapping screws (Core 4). This seal is what *forces* all incoming air to go *through* the filter media (Core 1), rather than leaking around its edges.

The “Unfiltered Air” Logic: A missing, cracked, or “flat-spotted” gasket is a critical failure. It creates a path of least resistance. Air (and dust) will bypass the filter entirely, flowing through the gap in the seal. This sends 100% unfiltered, dirty air directly into the HVAC system, destroying the evaporator. This FAW J6P External Air Filter gasket is just as important as the filter itself.

2. Component: ‘Cross recessed pan head tapping screw’ (CQ2714816) – Qty 2

This (Mark 5) is the set of two screws that provides the clamping force for the seal.

The Clamping Logic: These two screws (often supplemented by plastic clips) are what draw the cover (Box B) down onto the base (Box A). Their job is to apply the even pressure needed to fully compress the rubber gasket (8101573-A01) and create the perfect seal for the FAW J6P External Air Filter.

The Service Logic: A technician must inspect the gasket (Mark 3) every time they replace the filter element (Mark 4). If the gasket is hard, cracked, or missing, it must be replaced. A technician must also be careful not to over-tighten the tapping screws (Mark 5), as this will strip the plastic housing and prevent a good seal.

The following table provides the complete, detailed breakdown of all 5 component types specified for the FAW J6P External Air Filter system on the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 8101571-B27 | Box A-External Air Filter | 1 |

| 2 | 8101572-A01 | Box B-External Air Filter | 1 |

| 3 | 8101573-A01 | Rubber Gasket-External Air Filter | 1 |

| 4 | 8101574-A01 | Filter Element-External Air Filter | 1 |

| 5 | CQ2714816 | Cross recessed pan head tapping screw | 2 |

The specifications for the FAW J6P External Air Filter are defined by its critical role as the primary filtration unit for the cab’s HVAC system.

| Vehicle Application | FAW Jiefang CA3250P66K2L1T1E 6×4 Dump Truck |

| System Group | FAW J6P External Air Filter (Cabin Air Filter) |

| Primary Service Component | ‘Filter Element-External Air Filter’ (8101574-A01) |

| Filter Media | Pleated, Electrostatically-Charged Synthetic |

| Optional Media | Activated Charcoal (Odor & Gas Filtration) |

| Housing | Two-Piece (Box A & B) Polymer Shell |

| Housing Base | ‘Box A-External Air Filter’ (8101571-B27) |

| Housing Cover | ‘Box B-External Air Filter’ (8101572-A01) |

| Primary Seal | ‘Rubber Gasket-External Air Filter’ (8101573-A01) |

| Fasteners | ‘Cross recessed pan head tapping screw’ (CQ2714816) |

| Primary Function | Filters all incoming air for HVAC system & cab. |

| Service Interval | High-Frequency (Inspect/Replace regularly) |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.