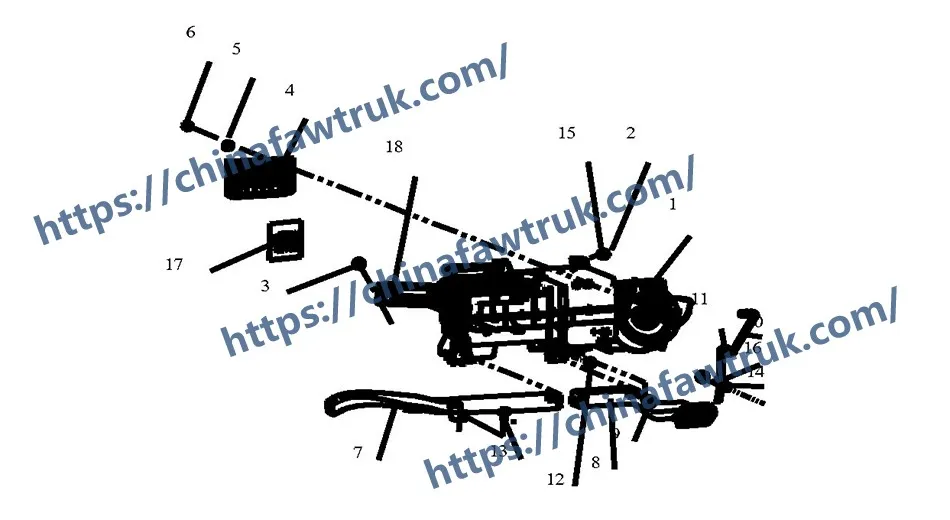

Welcome to this comprehensive deconstruction of the FAW J6P Air Conditioning Equipment for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck. This is not a single part, but a complex, multi-component system. This guide details the 18 critical parts that ensure optimal driver comfort and safety.

The FAW J6P Air Conditioning Equipment is a fully automatic climate control system, not a simple A/C. It is designed to heat, cool, filter, and dehumidify the air within the J6P cab, maintaining a set temperature regardless of the harsh exterior conditions of a quarry or construction site.

This teardown will analyze the entire system, from the main ‘Two-Box’ HVAC unit (the heater and evaporator) to the electronic control head, the air filtration system, the ducting, and the critical drain hoses. For a technician, a complete understanding of this system is essential for diagnosing refrigerant leaks, electrical faults, or poor performance.

A properly functioning FAW J6P Air Conditioning Equipment is a key factor in reducing driver fatigue and ensuring regulatory compliance. We will examine the logic of each part, from the main assemblies down to the specific hardware that holds them in place, ensuring a rattle-free and effective service.

This is the heart of the FAW J6P Air Conditioning Equipment, the main assembly hidden behind the dashboard that actually heats, cools, and moves the air.

1. Component: ‘Two-Box Assy – Automatic A/C’ (8100015-B27-C00) – Qty 1

This (Mark 1) is the main HVAC (Heating, Ventilation, and Air Conditioning) unit. The term “Two-Box” refers to the two main heat exchangers contained within its single, large polymer housing: the heater core and the evaporator core.

The Heater Core Logic: This is a small radiator inside the “Two-Box” assembly. Hot engine coolant is piped to it, and the blower fan forces cab air through its fins to provide heat.

The Evaporator Core Logic: This is the “cold” radiator. High-pressure liquid refrigerant (R134a) flows into it and expands into a gas, causing it to become ice-cold. Air blown through it is rapidly cooled and dehumidified. This is the “conditioning” part of the s FAW J6P Air Conditioning Equipment.

The “Automatic” Logic: This assembly also contains multiple electric servo motors that control “blend doors.” These doors automatically mix air from the hot and cold cores to achieve the precise temperature set on the control panel (Core 2), without the driver having to manually adjust from hot to cold.

The Blower Logic: The main electric blower motor (fan) is also integrated into this housing, providing the high-volume airflow required to heat or cool the large J6P cab quickly.

The Service Logic: This ‘Assy’ is a “dashboard-out” job to replace. A failure here is a major service event, often due to a leaking heater core (smell of coolant in the cab, fog on the windshield) or a refrigerant leak from the evaporator core. It is mounted using hardware like the M6 bolts (Mark 2).

These are the “brains” and user-interface components of the FAW J6P Air Conditioning Equipment.

1. Component: ‘Automatic A/C Control Mechanism Assy’ (8112010-B27-C00) – Qty 1

This (Mark 18) is the climate control “head unit” in the dashboard. This is the electronic module with the buttons, dials, and screen that the driver interacts with.

The “Automatic” Logic: As an “Automatic” unit, it houses a microcomputer. The driver sets a target temperature (e.g., 22°C). The computer then takes inputs from in-cab and ambient temperature sensors and automatically controls the blend doors, fan speed, and A/C compressor to maintain that temperature perfectly.

The Interface Logic: This unit controls all functions: temperature, fan speed, airflow mode (e.g., defrost, face, foot), and A/C compressor on/off. A failure here (e.g., dead screen, non-responsive buttons) can render the entire FAW J6P Air Conditioning Equipment useless.

2. Component: ‘A/C Usage & Maint. Warning Label (Chinese/English)’ (8100201AA01J) – Qty 1

This (Mark 17) is a mandatory information label, typically placed in the engine bay or on the HVAC box.

The Service Logic: This label’s logic is to inform the technician. It provides the most critical information needed to service the FAW J6P Air Conditioning Equipment: the exact *type* of refrigerant (e.g., R134a), the system’s *capacity* (e.g., 850g), and the specific *type* of compressor oil to use (e.g., PAG 46). Using the wrong information will destroy the system.

This is one of the most important service items in the entire FAW J6P Air Conditioning Equipment, especially for a dump truck.

1. Component: ‘External Air Filter Assy’ (8101570-B27) – Qty 1

This (Mark 4) is the cabin air filter assembly. It is the first line of defense for all air entering the cab.

The Filtration Logic: This assembly contains a replaceable, pleated filter element. Its job is to trap all airborne contaminants *before* they enter the HVAC unit. For a CA3250P66K2L1T1E operating in dusty quarries or construction sites, this means trapping massive amounts of silica dust, pollen, soot, and road grime.

The Health Logic: This filter directly protects the driver’s respiratory health, ensuring the air inside the cab is clean, even when the air outside is hazardous. Many versions are also “charcoal-activated” to filter out exhaust fumes and odors.

The System Protection Logic: This filter is also critical for the health of the FAW J6P Air Conditioning Equipment. It prevents the high-density fins of the evaporator core (Core 1) from becoming caked in a “blanket” of dust, which would block all airflow, cause the system to freeze over, and lead to total failure.

The Service Logic: A clogged filter is the #1 cause of “poor A/C performance” or “low airflow.” This filter is a regular maintenance item and must be replaced often. It is held in place by its own housing, which is secured by nuts (Mark 6) and washers (Mark 5).

This group of components forms the “delivery network,” channeling the conditioned air from the main HVAC unit (Core 1) to the driver and passenger.

1. Component: ‘Driver Foot Air Duct Assy’ (8101160-A01) – Qty 1

This (Mark 7) is the molded plastic duct that directs air specifically to the driver’s footwell.

2. Component: ‘Passenger Foot Air Duct Assy’ (8101185-B27-C00) – Qty 1

This (Mark 8) is the corresponding duct for the passenger’s footwell.

The “Air Delivery” Logic: The FAW J6P Air Conditioning Equipment relies on these ducts to transport air efficiently. They are designed to fit within the extremely tight confines of the dashboard, routing around steering columns and electrical boxes.

The “Assy” Logic: They are ‘Assemblies’ because they are not just hollow tubes. They include foam-gasket seals at their connection points. These seals are critical. They prevent the conditioned air from leaking out behind the dash, ensuring maximum airflow and pressure reaches the vents.

The Service Logic: These ducts are held in place by tapping screws (Mark 9). A common fault is a “rattle” if a duct comes loose, or “poor airflow” if a foam seal has degraded.

This is one of the most simple, yet most critical, sub-systems of the FAW J6P Air Conditioning Equipment. Failure here leads to major interior damage.

1. Component: ‘Drain Hose’ (8107066-A01) – Qty 1

This (Mark 10) is a flexible rubber hose. Its sole job is to drain the condensation (water) that the evaporator core (Core 1) pulls from the air.

2. Component: ‘Drain Hose Grommet’ (8107047-A01) – Qty 1

This (Mark 11) is the rubber grommet that provides a perfect seal as the drain hose passes through the cab’s firewall to the outside. This prevents fumes, noise, and engine heat from entering the cab.

3. Component: ‘Drain Hose Mounting Bracket’ (8100106-A01) – Qty 1

This (Mark 14) is a steel bracket that secures the hose.

4. Component: ‘Plastic Strap’ (T67414646) – Qty 1

This (Mark 16) is a plastic zip-tie, used with the bracket to clamp the hose in place.

The “Routing” Logic: This system is critical. The bracket and strap ensure the hose has a constant downward slope and is routed safely, away from hot exhaust manifolds (which would melt it) or spinning shafts.

The Failure Logic: This is a top-tier diagnostic item for any FAW J6P Air Conditioning Equipment. If this hose becomes clogged (by spiders, mud, or debris), the water *will* back up. The HVAC box will fill with water and overflow, pouring into the passenger footwell. This soaks the carpet, destroys electronic control modules, and causes a severe mold/mildew problem.

This diverse group of hardware is used to mount all the components of the FAW J6P Air Conditioning Equipment.

1. Component: ‘Hex Head Bolt’ (CQ1500620) – Qty 3

2. Component: ‘Large Washer’ (Q40206) – Qty 3

This (Mark 2 & 15) M6 bolt and large washer combination is likely used to secure the main ‘Two-Box Assy’ (Core 1) to the dashboard’s structural frame. The large washer distributes the load.

3. Component: ‘Hex Nut’ (CQ34008) – Qty 4

4. Component: ‘Washer’ (Q40108) – Qty 4

This (Mark 6 & 5) M8 nut and washer set is used to secure the ‘External Air Filter Assy’ (Core 3) to its mounting studs.

5. Component: ‘Cross recessed pan head tapping screw’ (CQ2714219) – Qty 4

6. Component: ‘Cross recessed pan head tapping screw’ (CQ2714813) – Qty 2

These (Mark 3 & 9) are self-tapping screws. Their logic is to fasten plastic components, such as the air ducts (Core 4), directly to plastic mounting bosses. They are fast to install and vibration-resistant.

7. Component: ‘Combination Bolt’ (CQ1460820) – Qty 2

8. Component: ‘Hex Flange Nut’ (CQ39606) – Qty 2

This (Mark 13 & 12) M8 combination bolt and flange nut set is likely used to secure the ‘Drain Hose Mounting Bracket’ (Core 5) to the chassis. The “combination” and “flange” features are both designed to resist loosening from vibration.

The following table provides the complete, detailed breakdown of all 18 component types specified for the FAW J6P Air Conditioning Equipment system on the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 8100015-B27-C00 | Two-Box Assy – Automatic A/C | 1 |

| 2 | CQ1500620 | Hex Head Bolt | 3 |

| 3 | CQ2714219 | Cross recessed pan head tapping screw | 4 |

| 4 | 8101570-B27 | External Air Filter Assy | 1 |

| 5 | Q40108 | Washer | 4 |

| 6 | CQ34008 | Hex Nut | 4 |

| 7 | 8101160-A01 | Driver Foot Air Duct Assy | 1 |

| 8 | 8101185-B27-C00 | Passenger Foot Air Duct Assy | 1 |

| 9 | CQ2714813 | Cross recessed pan head tapping screw | 2 |

| 10 | 8107066-A01 | Drain Hose | 1 |

| 11 | 8107047-A01 | Drain Hose Grommet | 1 |

| 12 | CQ39606 | Hex Flange Nut | 2 |

| 13 | CQ1460820 | Combination Bolt | 2 |

| 14 | 8100106-A01 | Drain Hose Mounting Bracket | 1 |

| 15 | Q40206 | Large Washer | 3 |

| 16 | T67414646 | Plastic Strap | 1 |

| 17 | 8100201AA01J | A/C Usage & Maint. Warning Label (Chinese/English) | 1 |

| 18 | 8112010-B27-C00 | Automatic A/C Control Mechanism Assy | 1 |

The specifications for the FAW J6P Air Conditioning Equipment are defined by its function as a complete, automatic climate control system.

| Vehicle Application | FAW Jiefang CA3250P66K2L1T1E 6×4 Dump Truck |

| System Group | FAW J6P Air Conditioning Equipment |

| System Type | Automatic Climate Control (HVAC) |

| Main HVAC Unit | ‘Two-Box Assy – Automatic A/C’ (8100015-B27-C00) |

| Control Unit | ‘Automatic A/C Control Mechanism Assy’ (8112010-B27-C00) |

| Filtration | ‘External Air Filter Assy’ (8101570-B27) |

| Air Ducts | ‘Driver/Passenger Foot Air Duct Assy’ |

| Drainage System | ‘Drain Hose’ & ‘Grommet’ (8107066-A01 / 8107047-A01) |

| Service Label | ‘A/C Usage & Maint. Warning Label’ (8100201AA01J) |

| Total Component Types | 18 |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.