Welcome to this crucial guide on the Cab Tilt Control Device for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck. This is the complete hydraulic and electric system that allows for engine service. This guide details the 7 critical components, from the dual-power pump to the switches and brackets, essential for safe maintenance.

The Cab Tilt Control Device is the heart of the CA3250P66K2L1T1E’s “cab-over-engine” design. Tilting the cab is the *only* way to access the engine, transmission, and cooling systems. This is not an optional accessory; it is a fundamental service mechanism that must be 100% reliable.

This system is a sophisticated “hybrid,” combining a high-pressure hydraulic pump (for manual operation) with an integrated electric motor (for effortless electric lifting). This teardown will analyze the pump, its structural bracket, the control switch, and all the specialized, vibration-proof hardware.

A failure in the Cab Tilt Control Device is a critical failure. It can leave a technician stranded, unable to service a disabled truck, or worse, lead to a catastrophic hydraulic failure while the cab is raised. We will analyze the logic of each part to ensure a correct and safe repair, which is paramount for this assembly.

This is the heart and muscle of the entire Cab Tilt Control Device. It is a single, sophisticated assembly that handles all the hydraulic work.

1. Component: ‘Manual-Electric Integrated Pump – Cab Lift (Electric Lift)’ (5002070AB35J) – Qty 1

This (Mark 1) is a hybrid unit. The name “Manual-Electric Integrated” is key. It provides vital redundancy, which is a core feature of this system.

The Electric Lift Logic: The primary function is the ‘Electric Lift’ (电动举升). This assembly contains a high-torque 24V DC electric motor. When the technician activates the switch (Core 3), this motor drives an internal hydraulic pump (e.g., a gearotor pump) that draws fluid from its reservoir and sends it to the main lift cylinder.

This electric function is for convenience, speed, and safety. It allows a single technician to raise the multi-ton cab in under a minute without any physical effort, while standing at a safe distance to observe the lift.

The Manual Override Logic: The “Manual” (手) part is the critical backup. If the truck’s battery is dead or the electric motor fails, the technician is not stranded. The Cab Tilt Control Device pump has a dedicated socket for a manual pump handle (typically the truck’s jack handle).

By inserting the handle and moving a separate release valve, the technician can *manually* operate the same hydraulic piston, raising or lowering the cab. This redundancy is essential for field service.

The Hydraulic Logic: This ‘Assy’ is a self-contained hydraulic system. It includes the pump (electric/manual), a hydraulic fluid reservoir (which must be filled with the correct-spec fluid, like AW 32/46), and the main high-pressure lift ram/cylinder. It also contains the internal check valves and release valves that lock the cab in place, preventing it from falling.

The Service Logic: This unit is generally sealed. Service involves checking for hydraulic fluid leaks from the piston seals, fittings, or reservoir gasket. Electrical service involves testing the motor and solenoid. A technician must also know the bleeding procedure, as air in the Cab Tilt Control Device system will cause a “spongy” or jerky lift. A failure of the internal pump or motor typically requires a full replacement of the 5002070AB35J assembly.

This component is the dedicated, high-strength foundation. It is the bridge between the heavy pump assembly and the truck’s chassis.

1. Component: ‘Electric Pump Bracket Assy’ (5002130AB35J) – Qty 1

This (Mark 5) is not a simple “L” bracket. It is a ‘Bracket Assy’ (支架总成), meaning it is a heavy-duty, fabricated steel component, likely with multiple, robotically-welded gussets and plates for maximum strength.

The Load-Bearing Logic: This bracket must securely anchor the heavy pump assembly (Core 1) to the truck’s chassis frame. It is engineered to handle massive, multi-axis forces.

It must withstand the immense torque of the electric motor starting (torsional load), the leveraging force of a technician manually pumping (lateral load), and the constant, high-frequency vibration from the chassis (vibratory load).

The Alignment Logic: This bracket provides the precise, pre-drilled mounting holes for both the chassis (using M10 bolts) and the pump (using M12 bolts). This ensures the Cab Tilt Control Device pump is mounted in the correct orientation and position, free of any stress or twist.

The Service Logic: This bracket is a key inspection point. It is mounted directly to the chassis, exposed to road salt, water, and mud. A technician must inspect this bracket for stress fractures (especially at the welds) or severe corrosion, either of which could lead to a catastrophic failure of the entire Cab Tilt Control Device. It is secured by the M10 bolts (Core 4).

This component is the human-machine interface for the *electric* operation of the Cab Tilt Control Device.

1. Component: ‘Hydraulic Tilting Switch Assy’ (5002075AB35J) – Qty 1

This (Mark 3) is a heavy-duty switch assembly, not a standard dash switch. It is designed to be weatherproof and withstand industrial use.

The Electrical Logic: This ‘Switch Assy’ is a momentary-on rocker switch. When pressed and held, it completes a circuit to a high-amperage relay, which in turn sends power to the pump motor (Core 1). It does not handle the full motor load itself, but acts as the “trigger” for the main power relay.

The Safety Interlock Logic: This switch is never placed inside the cab. It is always mounted on the *outside* of the vehicle, near the pump. This is a critical, mandatory safety design. It forces the operator to stand on the ground, with a clear line of sight of the cab, the front suspension, and any surrounding hazards *while* the cab is in motion.

The Weatherproof Logic: As an exterior-mounted switch, this assembly is environmentally sealed (e.g., to an IP65 or higher rating). It has internal rubber gaskets and a sealed wire pigtail to prevent water, dust, and hydraulic fluid from penetrating the contacts, which would cause a short circuit.

The Service Logic: When the electric tilt function fails, this switch is a primary suspect (after the fuse). A technician can test this component of the Cab Tilt Control Device with a multimeter to check for continuity. It is mounted with two M8 bolts (Core 4) and is a simple plug-and-play replacement.

This group contains the three distinct sets of specialized, vibration-proof hardware used to assemble the entire Cab Tilt Control Device.

1. Component: ‘Combination Bolt’ (CQ1461040F6) – Qty 4

These (Mark 2) are the M10 fasteners. Their logic is to provide the main structural connection between the ‘Electric Pump Bracket’ (Core 2) and the chassis frame.

2. Component: ‘Combination Bolt’ (CQ1460825F6) – Qty 2

These (Mark 4) are the smaller M8 fasteners. Their logic is to secure the lightweight ‘Hydraulic Tilting Switch’ (Core 3) to its mount.

3. Component: ‘Combination Bolt’ (CQ1461225) – Qty 6

These (Mark 6) are the M12 fasteners, the largest of the group. Their logic is to handle the highest-load connection: securing the heavy, high-torque ‘Integrated Pump’ (Core 1) to its bracket (Core 2).

4. Component: ‘External Tooth Lock Washer’ (Q41212) – Qty 6

This (Mark 7) is the critical locking component for the main pump bolts.

The “Combination Bolt” Logic: All three bolt types are “Combination Bolts” (组合螺栓). This means they have a pre-installed, captive washer (likely a flat washer). This design is purely for assembly speed and reliability, ensuring a washer is never missed.

The “External Tooth” Logic: The most critical joint—the M12 bolts holding the pump—does *not* rely on a simple captive washer. It uses a separate ‘External Tooth Lock Washer’ (外锯齿锁紧垫圈). These are made of high-carbon spring steel. The “teeth” are angled to bite into the soft metal of the bolt flange and the hard steel of the bracket. This creates a powerful, physical, anti-vibration lock that prevents the pump from shaking loose. This is the most reliable fastener for the Cab Tilt Control Device.

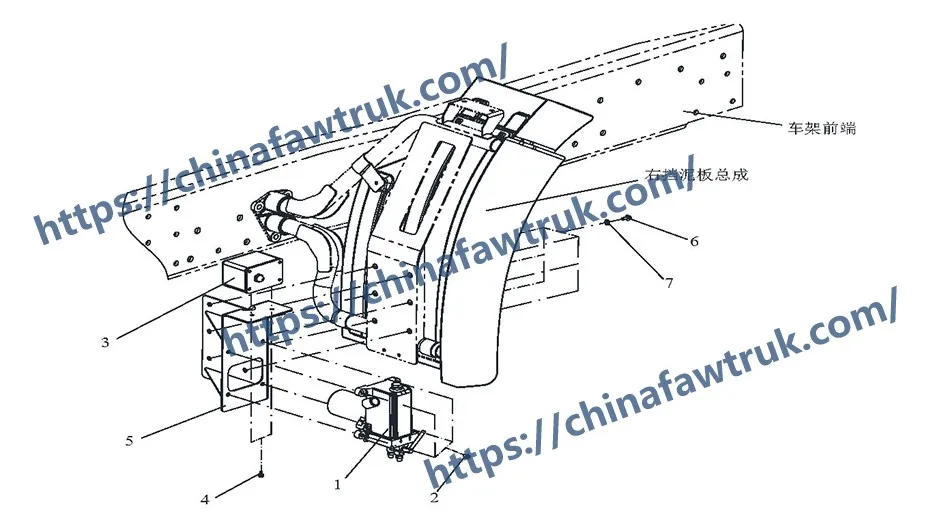

The following table provides the complete, detailed breakdown of all 7 component types specified for the Cab Tilt Control Device system on the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 5002070AB35J | Manual-Electric Integrated Pump – Cab Lift (Electric Lift) | 1 |

| 2 | CQ1461040F6 | Combination Bolt | 4 |

| 3 | 5002075AB35J | Hydraulic Tilting Switch Assy | 1 |

| 4 | CQ1460825F6 | Combination Bolt | 2 |

| 5 | 5002130AB35J | Electric Pump Bracket Assy | 1 |

| 6 | CQ1461225 | Combination Bolt | 6 |

| 7 | Q41212 | External Tooth Lock Washer | 6 |

The specifications for the Cab Tilt Control Device are defined by its dual-power, high-reliability design for safe vehicle service.

| Vehicle Application | FAW Jiefang CA3250P66K2L1T1E 6×4 Dump Truck |

| System Group | Cab Tilt Control Device |

| Primary Component | ‘Manual-Electric Integrated Pump’ (5002070AB35J) |

| Operation Mode 1 | Electric (24V DC Motor Driven) |

| Operation Mode 2 | Manual (Hydraulic Jack Handle Override) |

| Control Interface | ‘Hydraulic Tilting Switch Assy’ (5002075AB35J) |

| Main Bracket | ‘Electric Pump Bracket Assy’ (5002130AB35J) |

| Hardware 1 (Pump Mount) | M12 Combination Bolt (Qty 6) |

| Locking Hardware 1 | ‘External Tooth Lock Washer’ (Qty 6) |

| Hardware 2 (Bracket Mount) | M10 Combination Bolt (Qty 4) |

| Hardware 3 (Switch Mount) | M8 Combination Bolt (Qty 2) |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.