Le Ensemble de couvercle supérieur de transmission FAW serves as the kinetic interface between the driver and the 6G55 gearbox. Acting as the command module for torque management, this assembly houses the precise linkage mechanisms required to translate manual gear selection into internal fork movement. Maintenir l'intégrité structurelle du Ensemble de couvercle supérieur de transmission FAW is critical for ensuring smooth transitions and preventing drivetrain shock.

Ensemble de couvercle supérieur de transmission FAW

In the heavy-duty logistics sector, transmission reliability is non-negotiable. Le Ensemble de couvercle supérieur de transmission FAW acts as the primary shield and control center for the transmission’s upper architecture. It is not merely a lid; it is a calibrated mechanical system that must endure millions of shift cycles. When a driver manipulates the gear stick, the force is routed directly into this assembly. The internal rocker arms and shafts must withstand high leverage forces without flexing. Si le Ensemble de couvercle supérieur de transmission FAW loses its dimensional stability due to fatigue or poor-quality casting, the result is “gear hunting” or an inability to fully engage a specific ratio.

En outre, this assembly plays a vital role in environmental isolation. The 6G55 transmission operates in grueling conditions, from dusty mines to rain-soaked highways. Le Ensemble de couvercle supérieur de transmission FAW utilizes a system of felt washers, dust cups, and precision-machined mating surfaces to create an impermeable barrier. This prevents abrasive silica dust and moisture from entering the gearbox oil. Contamination is the leading cause of premature bearing and gear failure. Donc, the sealing capability of the Ensemble de couvercle supérieur de transmission FAW is directly linked to the total lifecycle cost of the vehicle.

Pour les gestionnaires de flotte, understanding the breakdown of this component is essential for predictive maintenance. By treating the Ensemble de couvercle supérieur de transmission FAW as a serviceable unit rather than a static part, technicians can identify wear in bushings and pins before they escalate into major transmission overhauls. The following sections detail the engineering logic and specific components that make this assembly a cornerstone of the FAW 6G55 transmission’s durability.

The engineering architecture of the Ensemble de couvercle supérieur de transmission FAW prioritizes rigidity and friction management. The core of the system revolves around the Shift rocker axis (Partie no. 6G55-8071) et le Select rocker axis (Partie no. 6G55-8011). These axes are manufactured from high-grade steel, often subjected to induction hardening processes to resist surface wear. They rotate within specialized bushings, comme le Bush of shift rocker axis (Partie no. 6G55-8084). This material pairing—hardened steel on a softer bushing—is a deliberate design choice within the Ensemble de couvercle supérieur de transmission FAW to ensure that wear is concentrated on the replaceable bushing rather than the expensive shaft.

Precision kinematics are achieved through the Shift rocker arm (Partie no. 6G55-8077) et le Select rocker arm (Partie no. 6G55-8027). These components are forged to withstand the sudden torque application of a rapid gear change. The geometry of these arms in the Ensemble de couvercle supérieur de transmission FAW is calculated to provide the optimal mechanical advantage, reducing the physical effort required by the driver while maximizing the force applied to the internal shift forks. Any deviation in the casting dimensions of these arms would result in a “notchy” or heavy shift feel, contributing to driver fatigue.

The assembly also integrates critical safety interlocks. Le Pin of neutral position switch (Partie no. 6G55-8955) is a prime example of electromechanical integration. This pin physically interacts with the neutral switch sensor, providing a signal only when the transmission is safely out of gear. This feature of the Ensemble de couvercle supérieur de transmission FAW is crucial for the vehicle’s starting circuit logic, preventing the engine from cranking while in gear. De la même manière, le Power switch of backup light (Partie no. WK-118-6G55) is mechanically actuated by the internal rail movement, ensuring immediate illumination of reverse lights for job site safety.

Enfin, the mounting strategy employs a high-density bolt pattern using fasteners like Boulon (Partie no. Q150B1065) et Boulon (Partie no. Q150B0850). Le Ensemble de couvercle supérieur de transmission FAW is subjected to intense high-frequency vibration from the diesel engine. To prevent self-loosening, these bolts are often paired with tensioning elements. The rigidity provided by this fastening system ensures that the shift rails remain perfectly parallel to the main shafts, preventing the dreaded “gear pop-out” phenomenon under load.

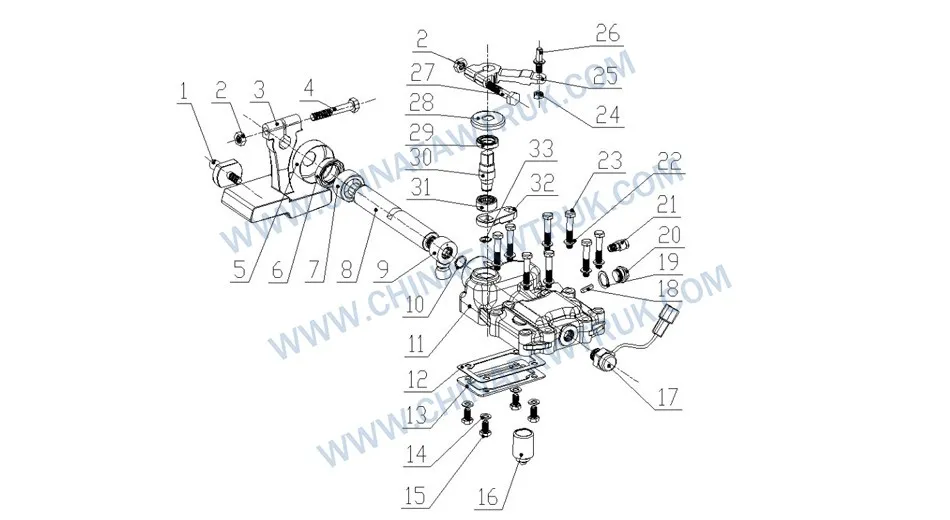

Vous trouverez ci-dessous le catalogue complet de pièces pour le Ensemble de couvercle supérieur de transmission FAW. This list includes all structural linkage, sealing elements, and fastening hardware required for a complete overhaul.

| Non. | Code (Numéro de pièce.) | Nom | Nombre (Qté) |

|---|---|---|---|

| 1 | 6G55-8076 | Pin of shift rocker arm | 1 |

| 2 | Q340B10 | Noix | 2 |

| 3 | 6G55-8077 | Shift rocker arm | 1 |

| 4 | Q150B1065 | Boulon | 1 |

| 5 | 6G55-8023 | Dust cup | 1 |

| 6 | 28X42X11DC01-6G55 | Rondelle en feutre | 1 |

| 7 | 6G55-8084 | Bush of shift rocker axis | 1 |

| 8 | 6G55-8071 | Shift rocker axis | 1 |

| 9 | 6G55-8075 | Pousser le bloc | 1 |

| 10 | 6G55-8035 | Anneau | 1 |

| 11 | 6G55-8021 | Shift rocker lid | 1 |

| 12 | 6G55-8022 | Shift rocker lid | 1 |

| 13 | 6G55-8025 | Cover board | 1 |

| 14 | Q40008 | Flap gasket | 4 |

| 15 | Q150B0816 | Boulon | 4 |

| 16 | 6G55-8053 | Positioning seat | 1 |

| 17 | WK-118-6G55 | Power switch of backup light | 1 |

| 18 | 6G55-8955 | Pin of neutral position switch | 1 |

| 19 | WTD25X18X1.5-6G55 | Drain plug gasket | 1 |

| 20 | WTM18X9-6G55 | Plug screw | 1 |

| 21 | Q901 | Ventilation plug | 1 |

| 22 | Q40008 | Flap gasket | 8 |

| 23 | Q150B0850 | Boulon | 8 |

| 24 | Q340B08 | Noix | 1 |

| 25 | 6G55-8027 | select rocker arm | 1 |

| 26 | 6G55-8921 | Pin of select rocker arm | 1 |

| 27 | Q150B1050 | Boulon | 1 |

| 28 | 6G55-8083 | Dust cup | 1 |

| 29 | 20X30X7DC01-6G55 | Rondelle en feutre | 1 |

| 30 | 6G55-8011 | select rocker axis | 1 |

| 31 | HK222812 | Palier | 1 |

| 32 | 6G55-8085 | Pousser le bloc | 1 |

| 33 | Q43114 | Anneau | 1 |

To fully understand the Ensemble de couvercle supérieur de transmission FAW, we must analyze the specific role of its sealing infrastructure. Le Rondelle en feutre (Partie no. 20X30X7DC01-6G55) et Dust cup (Partie no. 6G55-8023) form the first line of defense. Unlike rubber seals that may crack in extreme cold, felt retains oil, creating a self-lubricating barrier that traps fine particulate matter. If these components are neglected during a rebuild of the Ensemble de couvercle supérieur de transmission FAW, the shift rails will ingest grit. This abrasive paste will score the shafts, leading to hydraulic leaks and a stiff, grinding shift action that infuriates drivers.

The structural rigidity of the assembly is maintained by the Positioning seat (Partie no. 6G55-8053) et le Cover board (Partie no. 6G55-8025). These static components provide the necessary abutment surfaces for the moving linkage. Au fil du temps, vibration can cause fretting wear at these contact points. Un lâche Cover board sur le Ensemble de couvercle supérieur de transmission FAW allows moisture ingress, which can rust the internal springs and detent balls. Donc, inspecting these flat surfaces for pitting or warping is just as important as checking the moving gears.

Le Pousser le bloc (Partie no. 6G55-8085) is the critical translator of motion within the Ensemble de couvercle supérieur de transmission FAW. It converts the rotational energy of the rocker axis into linear displacement. Because this block slides against the shift forks, it is a high-wear item. As the block wears down, le “throw” of the gear stick increases. Eventually, the driver may hit the physical stop of the stick before the gear is fully engaged inside the transmission. Replacing this block restores the crisp, short-throw feel that defines a well-maintained 6G55 unit.

Enfin, le Palier (Partie no. HK222812) is a needle roller bearing designed for high radial loads in a compact space. Located at the pivot points of the axes, this bearing ensures friction-free rotation. If a technician uses a hammer to force the axis during disassembly, this delicate bearing can be crushed. A damaged bearing in the Ensemble de couvercle supérieur de transmission FAW will cause the shift lever to bind or stick, making it difficult to find neutral. Professional installation using a press is mandatory to preserve the integrity of this component.

A proactive maintenance strategy for the Ensemble de couvercle supérieur de transmission FAW begins with external inspection. Technicians should regularly check the condition of the Ventilation plug (Partie no. Q901). This small breather allows the transmission to equalize pressure as it heats up. If it becomes clogged with mud or grease, internal pressure will build up, forcing oil past the Rondelle en feutre and gaskets. A simple cleaning of this plug during every oil change can prevent seal failure and extend the life of the entire assembly.

Fastener integrity is another pillar of maintenance. Le Ensemble de couvercle supérieur de transmission FAW is secured by multiple bolts, y compris Boulon (Partie no. Q150B0816) et Noix (Partie no. Q340B10). Due to the high-torque nature of the 6G55 transmission, chassis flex can cause these fasteners to back out over time. A loose top cover not only leaks oil but can also misalign the shift forks, leading to bent rails. We recommend checking the torque on these accessible bolts every 20,000 kilometers as part of a standard service loop.

When leaks do occur, le Flap gasket (Partie no. Q40008) et Drain plug gasket (Partie no. WTD25X18X1.5-6G55) are the usual culprits. These should be considered single-use items. Reusing a crushed gasket on the Ensemble de couvercle supérieur de transmission FAW is a false economy that invariably leads to repeat repairs. Always keep a stock of these low-cost consumables to ensure that every time the cover is opened, it is resealed to factory specifications.

The market is flooded with aftermarket alternatives, mais le Ensemble de couvercle supérieur de transmission FAW requires the metallurgical precision that only genuine FAW parts can provide. An aftermarket Shift rocker arm may look identical, but if the steel lacks the correct heat treatment, it will wear prematurely or snap under heavy load. The downtime cost of a broken transmission far outweighs the savings of buying a generic component.

En outre, genuine parts guarantee geometric compatibility. Le Ensemble de couvercle supérieur de transmission FAW relies on the precise interaction of over 30 composants. Si le Anneau (Partie no. Q43114) ou Pin of shift rocker arm (Partie no. 6G55-8076) is out of tolerance by even a fraction of a millimeter, the entire shift linkage will feel loose and imprecise. Genuine parts ensure that the “click-clack” positive engagement of the 6G55 transmission is preserved.

By adhering to the parts list provided in this guide and insisting on genuine replacements, you ensure the longevity and safety of your fleet. Protect your investment by maintaining the Ensemble de couvercle supérieur de transmission FAW with the same quality components used on the assembly line.

Pièces FAW, y compris l'ensemble bloc-cylindres, sont emballés avec soin pour garantir une livraison en toute sécurité. Chaque composant est sécurisé dans des matériaux de protection pour éviter tout dommage pendant le transport. Le réseau logistique garantit des expéditions ponctuelles dans le monde entier, soutenir des opérations de maintenance efficaces. Vous trouverez ci-dessous une image illustrant l'emballage standard des pièces de camion FAW., mettant en valeur l’attention portée aux détails dans la manipulation et le stockage.

Cette approche d'emballage minimise le risque de corrosion ou de dommages causés par les chocs., s'assurer que les pièces comme l'ensemble bloc-cylindres FAW arrivent en parfait état. Les clients peuvent compter sur la logistique de FAW pour une qualité et une fiabilité constantes.