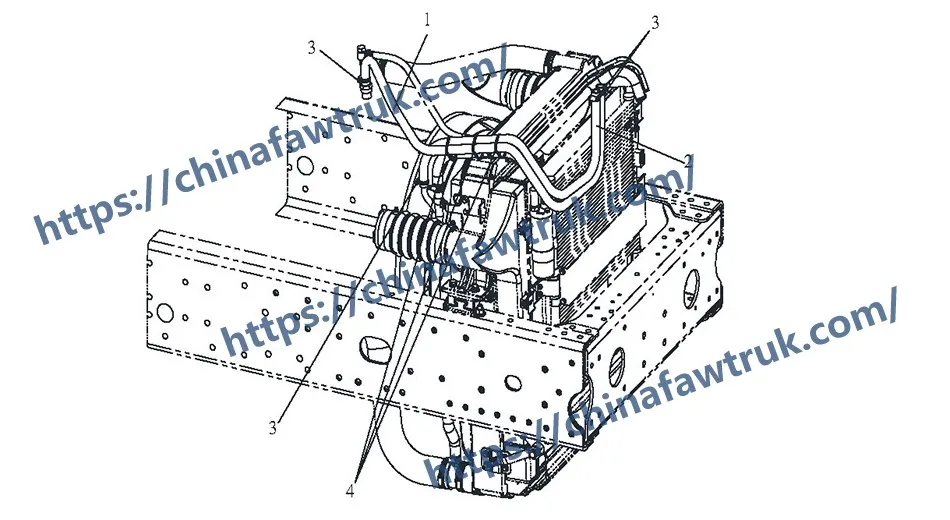

Welcome to this essential guide on the Tuyaux de chauffage FAW J6P Pour le FAW Jiefang CA3250P66K2L1T1E 6×4 tombereau. These are not just tubes; they are the critical arteries of the cab’s climate system, vital for driver safety and comfort in cold weather. Ce guide détaille les 4 critical parts that ensure a leak-proof heating circuit.

Le Tuyaux de chauffage FAW J6P system serves a dual purpose that is essential for the operation of a heavy-duty dump truck. Its most obvious function is driver comfort, providing heat to the cab in sub-zero conditions. Plus important encore, it is a critical safety system, as it provides the hot coolant necessary for the HVAC unit to “décongeler” et “defog” the massive front windscreen.

This teardown will analyze the full component set, including the high-temperature EPDM hoses, the stainless steel worm-drive clamps, and the protective routing strap. Le Tuyaux de chauffage FAW J6P must reliably transport pressurized, high-temperature engine coolant (a mix of glycol and water) from the engine block, through the firewall, to the cab’s heater core, et retour au moteur.

A failure in this system is a critical service event. Une fuite dans le Tuyaux de chauffage FAW J6P can dump hot, liquide de refroidissement sous pression, potentially fogging the cab or causing an engine to overheat if the coolant level drops too low. Pour un technicien, understanding this system is key to diagnosing leaks, “pas de chaleur” plaintes, and ensuring a safe, long-lasting repair.

These two components are the primary arteries of the Tuyaux de chauffage FAW J6P système. They are the flexible conduits that move the heat from the engine to the cab.

1. Composant: ‘Inlet Hose’ (8116711-14B) – Quantité 1

Ce (Marque 1) est le “pression” ou “entrée” hose. It carries the hottest coolant (up to 100°C / 212° F) *from* a port on the engine block *to* the inlet of the heater core, which is located inside the cab’s HVAC unit.

La logique matérielle (EPDM): This is not a simple tube. It is a high-specification hose made from EPDM (Monomère d'éthylène propylène diène) caoutchouc. EPDM is the industry-standard for cooling systems because it has an extremely high temperature tolerance and is chemically inert to ethylene glycol (antifreeze) and anti-corrosion additives.

The Reinforcement Logic: Le Tuyaux de chauffage FAW J6P system is pressurized to 15-20 psi. To prevent the hose from swelling, “ballooning,” or bursting, it is internally reinforced with a textile braid, often made of high-strength Aramid or polyester fibers. This internal skeleton contains the pressure, while the EPDM contains the fluid.

2. Composant: ‘Outlet Hose’ (8116712-14B) – Quantité 1

Ce (Marque 2) est le “retour” ou “sortie” hose. It completes the circuit, carrying the now slightly-cooler coolant *from* the heater core outlet *back* to the engine, typically connecting to the water pump to be re-circulated.

Le “Pre-Molded” Logique: Both of these Tuyaux de chauffage FAW J6P sont “pre-molded” ou “formed” tuyaux. They are manufactured with specific, complex bends and curves. Il s'agit d'une caractéristique de conception essentielle. A technician cannot replace these with a straight hose. The pre-molded shape is essential to route the hoses perfectly through the firewall and around hot, vibrating engine components without “kinking.”

Le “Kinking” Logique d'échec: A kink in a hose is a 100% flow blockage. If a cheap, straight hose is used and it kinks at the firewall, no coolant will reach the heater core. The driver will complain of “pas de chaleur,” and the system will appear to have failed, when in fact the wrong part was used. Only the correct pre-molded Tuyaux de chauffage FAW J6P will work.

La logique de service (Tuyaux): Hoses are wear items. Over many years, the EPDM will “harden” from heat cycles, losing its flexibility. This causes cracks to form, especially at the connection points, leading to slow leaks. Alternativement, the internal reinforcement can break down, causing the hose to feel “spongieux” ou “mushy.” A bulging hose is a sign of impending failure and must be replaced immediately.

These are arguably the most critical components of the Tuyaux de chauffage FAW J6P système. A high-quality hose is useless if the clamp fails.

1. Composant: ‘Worm-drive Hose Clamp Type B’ (CQ67627B) – Quantité 4

Ce (Marque 3) is a set of four ‘Worm-drive’ pinces, two for each hose (one at the engine side, one at the heater core side).

La logique de serrage: The clamp’s sole function is to provide a 360-degree, à haute pression, joint à l'épreuve des fuites. It compresses the flexible EPDM hose (Cœur 1) against the rigid metal pipe (ou “nipple”) of the engine and heater core.

Le “Worm-Drive” Logique: This mechanism provides high clamping force from a low input torque. UN “worm” (the screw) engages with slots in the band. As the screw is turned, it pulls the band tight. Ce “Tapez B” design specifies a “non-perforated” ou “rolled-edge” band. This is superior to cheap, slotted clamps, as the smooth inner band provides an even seal and will not cut into the rubber hose.

La logique matérielle (Stainless): These clamps are not plain steel. For a heavy-duty truck application, these are typically “W4” ou “W5” grade, meaning the band, logement, and screw are all made of high-grade stainless steel. This is mandatory for a component that lives in a high-heat, high-moisture environment and is constantly splashed with road salt and water. Plain steel clamps would rust, weaken, and fail, causing the hose to blow off.

La logique de service (Pinces): UN “weep” ou “drip” of coolant is the #1 symptom of a failing Tuyaux de chauffage FAW J6P système. This is almost always a failure of the clamp’s torque, not the hose itself. As the hose hardens with age, il “compresse,” and the clamp loses its tension.

A technician’s first step is to re-torque the clamps. Cependant, over-tightening is a common and costly mistake. A technician must use a nut driver, not a high-torque power tool, as it is very easy to strip the clamp’s threads or crack the plastic inlet/outlet pipe of the heater core, which necessitates a full dashboard removal.

This single, simple component is a crucial part of the Tuyaux de chauffage FAW J6P système, designed to prevent a specific type of failure.

1. Composant: « Sangle en plastique’ (T67437676) – Quantité 1

Ce (Marque 4) is an automotive-grade cable tie, commonly known as a zip-tie. Its part number designates it as a specific size and, le plus important, a specific material.

Le “Anti-frottement” Logique: This strap’s primary function is to secure the two Tuyaux de chauffage FAW J6P (Inlet and Outlet) *together*, or to secure them to a fixed bracket on the chassis or engine.

C'est un point critique “anti-vibration” ou “anti-frottement” measure. Without this strap, the two hoses would vibrate independently, constantly rubbing against each other or against a sharp metal edge of the chassis. Sur des milliers de kilomètres, this constant, high-frequency “sawing” action will chafe through the outer rubber and inner reinforcement, causing a hose to burst.

Le “Routage” Logique: This strap also ensures the hoses follow their designated, safe path, keeping them away from moving components (like the fan belt) or extremely hot components (like the exhaust manifold or turbocharger).

La logique matérielle (Nylon 6/6): This is not a standard plastic strap. It is an automotive-grade tie made from “Nylon 6/6 with Heat Stabilizer.” This specific material is chosen for its high melting point and resistance to “drying out.” It can withstand the high radiant heat of the engine bay (100°C+) for years without becoming brittle and snapping, which a common hardware-store zip-tie would.

La logique de service (Sangle): It is common for technicians to cut this strap (T67437676) to gain access when replacing one of the Tuyaux de chauffage FAW J6P. It is *mandatory* that a new, equivalent high-temperature strap is installed. Failure to re-secure the hoses guarantees a premature failure of the new parts due to chafing.

Le tableau suivant fournit l'intégralité, ventilation détaillée de tous 4 types de composants spécifiés pour le Tuyaux de chauffage FAW J6P système sur le FAW Jiefang CA3250P66K2L1T1E 6×4 tombereau.

| Marque | Partie no. | Nom de la pièce | Quantité |

|---|---|---|---|

| 1 | 8116711-14B | Tuyau d'arrivée | 1 |

| 2 | 8116712-14B | Outlet Hose | 1 |

| 3 | CQ67627B | Worm-drive Hose Clamp Type B | 4 |

| 4 | T67437676 | Sangle en plastique | 1 |

Les spécifications pour le Tuyaux de chauffage FAW J6P are defined by their role as a high-temperature, high-pressure fluid transport system for the cab climate control.

| Demande de véhicule | FAW Jiefang CA3250P66K2L1T1E 6×4 Tombereau |

| Groupe système | Tuyaux de chauffage FAW J6P (Heater Core Supply) |

| Tuyau d'arrivée | ‘Inlet Hose’ (8116711-14B) |

| Outlet Hose | ‘Outlet Hose’ (8116712-14B) |

| Hose Material | EPDM Rubber (Monomère d'éthylène propylène diène) |

| Hose Reinforcement | Aramid or Polyester Textile Braid |

| Hose Design | Pre-Molded (Formed) to prevent kinking |

| Pinces | ‘Worm-drive Hose Clamp Type B’ (CQ67627B) |

| Clamp Quantity | 4 |

| Clamp Material | Acier inoxydable (W4/W5 Grade) |

| Routing Component | « Sangle en plastique’ (T67437676) |

| Système associé | Engine Cooling System, Cab HVAC Unit (Heater Core) |

Pièces FAW, y compris l'ensemble bloc-cylindres, sont emballés avec soin pour garantir une livraison en toute sécurité. Chaque composant est sécurisé dans des matériaux de protection pour éviter tout dommage pendant le transport. Le réseau logistique garantit des expéditions ponctuelles dans le monde entier, soutenir des opérations de maintenance efficaces. Vous trouverez ci-dessous une image illustrant l'emballage standard des pièces de camion FAW., mettant en valeur l’attention portée aux détails dans la manipulation et le stockage.

Cette approche d'emballage minimise le risque de corrosion ou de dommages causés par les chocs., s'assurer que les pièces comme l'ensemble bloc-cylindres FAW arrivent en parfait état. Les clients peuvent compter sur la logistique de FAW pour une qualité et une fiabilité constantes.