Bienvenue dans cette analyse technique définitive du Train de soupapes FAW J6P, le complet “engine breathing” et “frein moteur” système pour le FAW Jiefang CA3250P66K2L1T1E 6×4 camion à benne diesel.

This is not just a collection of parts; c'est un complexe “Assemblage logique” engineered for two primary purposes: precision airflow control and powerful, integrated vehicle retardation.

Le “logique” de ceci Train de soupapes FAW J6P is to perfectly choreograph the flow of air into and out of the engine’s cylinders, a task that dictates 100% of the engine’s power, efficacité, and emissions.

Le plus critique “Logique de conception” de ce spécifique Train de soupapes FAW J6P is its integration of a powerful “frein moteur” (Jake Frein). This is not an “frein sur échappement,” but a true “compression-release” frein. Ce système, which includes components like the ‘Pressure valve-rocker arm’ (Comp 17), uses high-pressure engine oil to force the exhaust valves open during the compression stroke, turning the engine into a massive air compressor. Ce “Logique de freinage” is essential for a heavy-duty dump truck, as it provides huge amounts of braking force without using the service (roue) freins, saving them from overheating and fading on long, descentes raides.

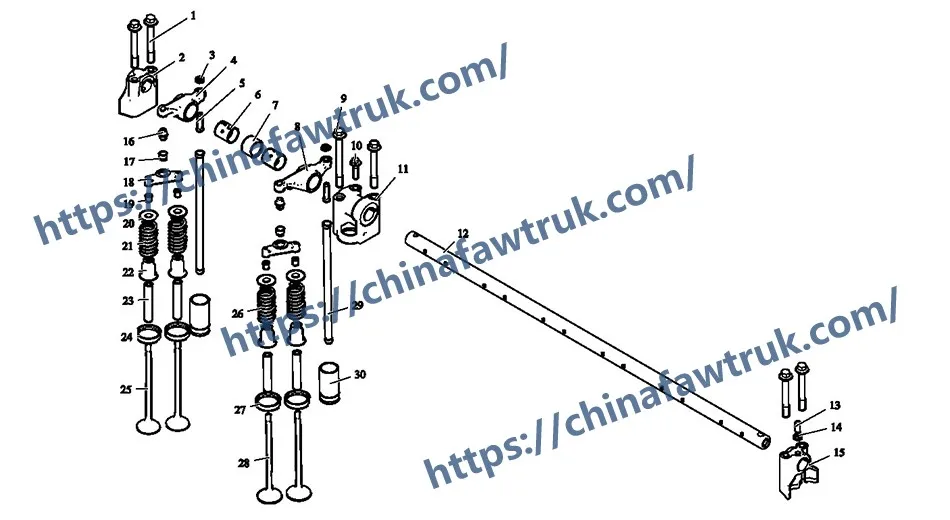

Ce guide expert est une ressource essentielle pour les reconstructeurs de moteurs, techniciens de flotte, et gestionnaires de pièces. We will deconstruct the entire 25-component group into its four primary “logique” systèmes: le “Logique d'actionnement des vannes” (the rocker arms and shafts that move the valves), la critique “Logique du frein moteur” (the high-pressure valves and pins), le “Valve Sealing & Logique de guidage” (the components inside the head), et le “Printemps & Retention Logic” (the parts that close the valves). Ceci est le guide complet du Train de soupapes FAW J6P.

This group forms the “pont” de la Train de soupapes FAW J6P. In an OHV (cam-in-block) moteur, these components transfer the “lift” from the camshaft (via pushrods, non représenté) to the tops of the valves.

1. Composants: ‘Rocker shaft assy’ (1007130-29D) & ‘Rocker shaft support’ (1007102-29D, 1007101-29D)

C'est le “structural foundation” of the valvetrain. The ‘Rocker shaft assy’ (Comp 12) is a hardened, hollow steel shaft. C'est “logique” est double: 1) It provides the rigid, precision-ground axle that the rocker arms pivot on. 2) C'est “hollow logic” is that it acts as the primary “oil galley,” delivering high-pressure oil from the head to lubricate the rocker arms and to *power* the engine brake system. This shaft is held in place by 5 ‘Rocker shaft supports’ (Comp 11) et 1 ‘Rear support’ (Comp 15), which are bolted to the cylinder head.

2. Composants: ‘Rocker arm-intake’ (1007121-29D) & ‘Rocker arm-exhaust’ (1007111-48D)

Ces (Comp 4 & 8) sont les “leviers” de la Train de soupapes FAW J6P. Leur “Multiplier Logic” is to act as a lever to multiply the cam’s lift. UN 1.5:1 rapport, Par exemple, means that for every 10mm the pushrod moves, the valve opens 15mm. This allows for aggressive valve lift with a smoother cam profile. The ‘Intake’ and ‘Exhaust’ rockers are different; the exhaust rocker (Comp 8) is a more complex component, as it must house the “Logique du frein moteur” (voir Noyau 2).

3. Composants: ‘Locking nut-valve adj. vis’ (1007113-29D) & ‘Adjusting screw-rocker arm’ (1007112-29D)

Ce (Comp 3 & 5) est le “Logique de facilité d'entretien” de la Train de soupapes FAW J6P. The ‘Adjusting screw’ (Comp 5) sits at the end of the rocker arm (pushrod side). C'est “logique” is to allow a technician to precisely set the “valve lash”—the tiny, critical gap (Par exemple, 0.015 pouces) dans le système. This gap is necessary to compensate for thermal expansion. The ‘Locking nut’ (Comp 3) locks the screw in place. Incorrect lash is a primary cause of noise, perte de puissance, et Train de soupapes FAW J6P échec.

This is the most advanced “logique” dans ce Train de soupapes FAW J6P, a feature essential for a heavy-duty dump truck. This is *not* an exhaust brake.

1. Le “Compression-Release” Logique:

Le “logique” of a “Jake Frein” is to turn the engine into an air compressor. When the brake is activated, a solenoid (non répertorié) sends high-pressure engine oil into the ‘Rocker shaft’ (Comp 12). This oil flows into the ‘Rocker arm-exhaust’ (Comp 8) and acts on the ‘Pressure valve-rocker arm’ (Comp 17). Ce “Hydraulic Logic” opens the valve, which pushes on a “slave piston” inside the rocker arm. This slave piston then *opens the exhaust valve* near the top of the compression stroke. This instantly releases all the compressed air, forcing the engine to “waste” its power. Cela crée un puissant, 200+ hp braking effect, saving the wheel brakes.

2. Composants: ‘Pressure valve’ (1007117-29D), ‘Ball seat’ (1007118-29D), & ‘Limit pin’ (1007103-29D)

C'est le “à haute pression” sub-assembly. The ‘Pressure valve’ (Comp 17) is the hydraulic “déclenchement.” The ‘Ball seat’ (Comp 18) is the pivot for the valve-actuating part of the rocker. The ‘Limit pin’ (Comp 7) est un “arrêt” that controls the travel of the engine brake mechanism. This entire system is what separates a standard Train de soupapes FAW J6P from a “robuste” Train de soupapes FAW J6P.

This group of components is located *inside* the cylinder head, but they are all critical, serviceable parts of the Train de soupapes FAW J6P.

1. Composants: 'Siège de soupape d'admission’ (1007016-36D) & « Siège de soupape d'échappement’ (1003013-36D)

C'est le “Logique d’étanchéité de combustion.” Les vannes doivent assurer l'étanchéité contre une surface parfaitement ronde., surface incroyablement dure. The cylinder head is too soft for this. Le “logique” voici pour insérer par pression deux types différents de « sièges de soupape »’ (Comp 24 & 25) dans la tête. Le « Siège de soupape d'échappement’ (Comp 25) est fait d'un matériau très dur, alliage d'acier à haute température (comme Stellite) to withstand superheated exhaust. Le « Siège de soupape d'admission’ (Comp 24) is a different hardened steel, cooled by the intake air. Leur “logique de service” is that they are “sacrificiel” and can be re-ground or replaced.

2. Composant: « Guide de soupape’ (1003014-29D)

Ce (Comp 23) est le “Precision Guide Logic.” La liste réclame 24 guides (12 admission, 12 échappement). Leur “logique” doit être remplaçable, manchon à faible friction (often bronze alloy) that is press-fit into the head. This guide is what holds the valve stem in perfect alignment as it moves up and down 15+ fois par seconde. A worn valve guide will cause high oil consumption and poor valve sealing.

3. Composant: ‘Valve guide oil seal assy’ (1007035-29D)

Ce (Comp 22) est le “Oil Control Logic.” C'est un petit, spring-loaded rubber seal that snaps onto the top of the valve guide. C'est “logique” is to allow a *microscopic* film of oil to travel down the valve stem for lubrication, but to prevent the “bain” of oil splashing around the Train de soupapes FAW J6P from being *sucked* into the engine on the intake stroke. Failed valve seals are a primary cause of blue smoke and oil consumption.

EXPLAIN:

Ce dernier groupe “logique” is to ensure the valves *close* quickly and completely, and to keep the entire assembly locked together at high RPM.

1. Composant: ‘Exhaust valve spring’ (1007022-29D)

Ce (Comp 21) est le “Closing Force Logic.” La liste réclame 12, one for each exhaust valve (intake springs are not on this list, but are similar). Le “logique” of this heavy-duty spring is to provide enough force to slam the valve shut against the high-pressure exhaust gas, perfectly sealing the cylinder. It must also be “à l'écoute” to the correct frequency to prevent “flotteur de soupape”—a condition at high RPM where the spring can’t keep up and the valve fails to close, leading to a collision with the piston.

2. Composant: ‘Valve spring seat’ (1007024-29D)

Ce (Comp 20) est le “Protection Logic.” La liste réclame 24 (one for each valve). Le Culasse FAW J6P is made of a softer metal (cast iron or aluminum). Le “logique” of this hardened steel “siège” is to sit *between* the spring and the head, preventing the high-pressure spring from “chewing” ou “digging” its way into the head casting over millions of cycles.

3. Composant: ‘Valve cotter’ (1007028-29D)

Ce (Comp 19) est le “Retention Logic.” La liste réclame 48 (two for each valve). These are the two tiny, wedge-shaped “keepers” that lock into a groove at the top of the valve stem. Le “logique” is that the spring’s force (pushing up on the retainer, non répertorié) forces these two cotters *together*, créer un “taper-lock” that holds the entire spring assembly onto the valve. These tiny parts are the only thing preventing the valve from dropping into the cylinder, which would destroy the entire Train de soupapes FAW J6P et moteur.

Le tableau suivant fournit l'intégralité, ventilation détaillée de tous 25 types de composants dans le Train de soupapes FAW J6P assemblée (avec frein moteur) Pour le FAW Jiefang CA3250P66K2L1T1E 6×4 tombereau.

| Marque | Partie no. | Nom de la pièce | Quantité |

|---|---|---|---|

| 1 | Q1820880 | Boulon à bride hexagonale | 10 |

| 2 | 1007104-29D (1007104B29d) | Bolt-rocker shaft support | 1 M8x20 |

| 3 | 1007113-29D | Locking nut-valve adjusting screw | 12 |

| 4 | 1007121-29D | Rocker arm-intake | 6 |

| 5 | 1007112-29D | Adjusting screw-rocker arm | 12 |

| 6 | 1007114-29D (1007114A29D) | Bushing-rocker arm | 12 |

| 7 | 1007103-29D | Limit pin-rocker arm | 12 |

| 8 | 1007111-48D (1007111-621-0000) | Rocker arm-exhaust | 6 |

| 9 | 1007106-48D (1007106A621-0000) | Bolt-rocker shaft support | 4 |

| 10 | Q1840835 | Boulon à bride hexagonale | 5 |

| 11 | 1007102-29D | Rocker shaft support | 5 |

| 12 | 1007130-29D (1007130A29D) | Rocker shaft assy | 1 |

| 13 | GB/T71-1985 | Slotted countersunk head screw M8x20 | 1 |

| 14 | Q340B08T12 | Type I hexagon nut | 1 |

| 15 | 1007101-29D | Rocker shaft rear support | 1 |

| 16 | 1007117-29D | Pressure valve-rocker arm | 12 |

| 17 | 1007118-29D | Ball seat-rocker arm | 12 |

| 18 | 1007012-29D (1007012-29ET) | Crosshead (Entièrement interchangeable) | 12 |

| 19 | 1007028-29D | Clavette de soupape | 48 |

| 20 | 1007024-29D | Siège de ressort de soupape | 24 |

| 21 | 1007022-29D | Exhaust valve spring | 12 |

| 22 | 1007035-29D (1007035A29D) | Valve guide oil seal assy | 24 |

| 23 | 1003014-29D (1003014M29D) | Guide de soupape | 24 |

| 24 | 1003013-36D | Siège de soupape d'échappement | 12 |

| 25 | 1007016-36D | Siège de soupape d'admission | 12 |

Les spécifications pour le Train de soupapes FAW J6P are defined by its dual function as an OHV actuation system and a compression-release engine brake.

| Demande de véhicule | FAW Jiefang CA3250P66K2L1T1E 6×4 Tombereau |

| Groupe système | Train de soupapes FAW J6P / Valvetrain Assembly |

| Type de système | Overhead Valve (OHV) / Cam-in-Block |

| Caractéristique clé | Integrated Compression-Release Engine Brake |

| Logique d'actionnement | ‘Rocker shaft assy’ (1007130-29D) with ‘Rocker arms’ |

| Logique du frein moteur | ‘Pressure valve-rocker arm’ (1007117-29D) – Quantité 12 |

| Valve Control | ‘Crosshead’ (1007012-29D) – (For 4-valve-per-cylinder design) |

| Wear Component (Guide) | « Guide de soupape’ (1003014-29D) – Quantité 24 |

| Wear Component (Scellage) | ‘Intake/Exhaust valve seat’ (1007016-36D / 1003013-36D) – Quantité 24 total |

| Oil Control Logic | ‘Valve guide oil seal assy’ (1007035-29D) – Quantité 24 |

| Retention Logic | ‘Valve cotter’ (1007028-29D) – Quantité 48 |

| Système associé | Complet Train de soupapes FAW J6P and Cylinder Head |

Pièces FAW, y compris l'ensemble bloc-cylindres, sont emballés avec soin pour garantir une livraison en toute sécurité. Chaque composant est sécurisé dans des matériaux de protection pour éviter tout dommage pendant le transport. Le réseau logistique garantit des expéditions ponctuelles dans le monde entier, soutenir des opérations de maintenance efficaces. Vous trouverez ci-dessous une image illustrant l'emballage standard des pièces de camion FAW., mettant en valeur l’attention portée aux détails dans la manipulation et le stockage.

Cette approche d'emballage minimise le risque de corrosion ou de dommages causés par les chocs., s'assurer que les pièces comme l'ensemble bloc-cylindres FAW arrivent en parfait état. Les clients peuvent compter sur la logistique de FAW pour une qualité et une fiabilité constantes.