مرحبا بكم في هذا التحليل الفني النهائي لل قطار صمام FAW J6P, الكامل “engine breathing” و “engine braking” نظام FAW Jiefang CA3250P66K2L1T1E 6×4 شاحنة تفريغ الديزل.

This is not just a collection of parts; إنه معقد “تجميع المنطق” engineered for two primary purposes: precision airflow control and powerful, integrated vehicle retardation.

ال “منطق” من هذا قطار صمام FAW J6P is to perfectly choreograph the flow of air into and out of the engine’s cylinders, a task that dictates 100% of the engine’s power, كفاءة, والانبعاثات.

الأكثر أهمية “منطق التصميم” من هذا محددة قطار صمام FAW J6P is its integration of a powerful “engine brake” (جيك بريك). This is not an “exhaust brake,” but a true “compression-release” الفرامل. هذا النظام, which includes components like the ‘Pressure valve-rocker arm’ (شركات 17), uses high-pressure engine oil to force the exhaust valves open during the compression stroke, turning the engine into a massive air compressor. هذا “Braking Logic” is essential for a heavy-duty dump truck, as it provides huge amounts of braking force without using the service (عجلة) brakes, saving them from overheating and fading on long, هبوط حاد.

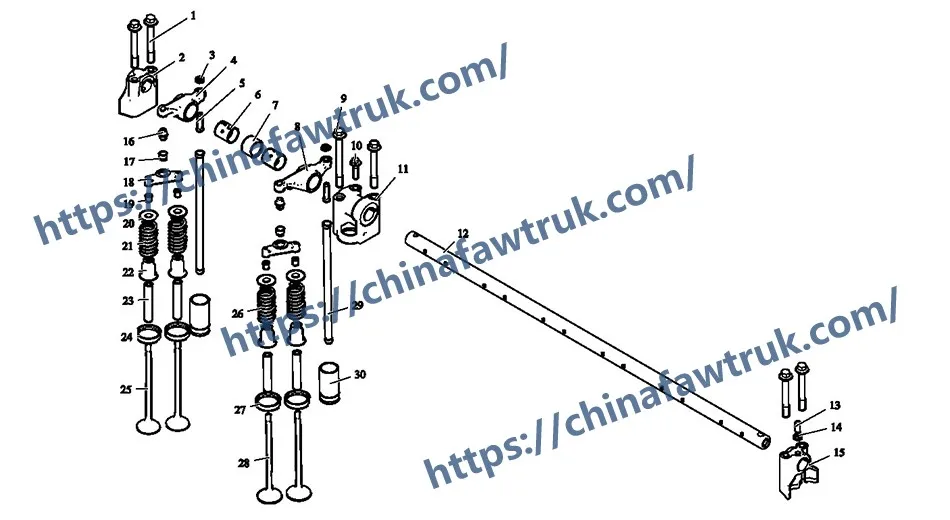

يعد دليل الخبراء هذا مصدرًا أساسيًا لمعيدي بناء المحركات, فنيو الأسطول, ومديري قطع الغيار. We will deconstruct the entire 25-component group into its four primary “منطق” أنظمة: ال “Valve Actuation Logic” (the rocker arms and shafts that move the valves), الحرجة “Engine Brake Logic” (the high-pressure valves and pins), ال “Valve Sealing & Guide Logic” (the components inside the head), و “ربيع & منطق الاحتفاظ” (the parts that close the valves). هذا هو الدليل الكامل ل قطار صمام FAW J6P.

This group forms the “كوبري” التابع قطار صمام FAW J6P. In an OHV (cam-in-block) محرك, these components transfer the “يرفع” from the camshaft (via pushrods, not shown) to the tops of the valves.

1. عناصر: ‘Rocker shaft assy’ (1007130-29د) & ‘Rocker shaft support’ (1007102-29د, 1007101-29د)

هذا هو “structural foundation” of the valvetrain. The ‘Rocker shaft assy’ (شركات 12) هو تصلب, hollow steel shaft. إنه “منطق” ذو شقين: 1) It provides the rigid, precision-ground axle that the rocker arms pivot on. 2) إنه “منطق أجوف” is that it acts as the primary “oil galley,” delivering high-pressure oil from the head to lubricate the rocker arms and to *power* the engine brake system. This shaft is held in place by 5 ‘Rocker shaft supports’ (شركات 11) و 1 "الدعم الخلفي."’ (شركات 15), which are bolted to the cylinder head.

2. عناصر: ‘Rocker arm-intake’ (1007121-29د) & ‘Rocker arm-exhaust’ (1007111-48د)

هؤلاء (شركات 4 & 8) هي “العتلات” التابع قطار صمام FAW J6P. هُم “Multiplier Logic” is to act as a lever to multiply the cam’s lift. أ 1.5:1 نسبة, على سبيل المثال, means that for every 10mm the pushrod moves, the valve opens 15mm. This allows for aggressive valve lift with a smoother cam profile. The ‘Intake’ and ‘Exhaust’ rockers are different; the exhaust rocker (شركات 8) is a more complex component, as it must house the “Engine Brake Logic” (see Core 2).

3. عناصر: ‘Locking nut-valve adj. أفسد’ (1007113-29د) & ‘Adjusting screw-rocker arm’ (1007112-29د)

هذا (شركات 3 & 5) هو “منطق الخدمة” التابع قطار صمام FAW J6P. The ‘Adjusting screw’ (شركات 5) sits at the end of the rocker arm (pushrod side). إنه “منطق” is to allow a technician to precisely set the “valve lash”—the tiny, critical gap (على سبيل المثال, 0.015 بوصة) في النظام. This gap is necessary to compensate for thermal expansion. The ‘Locking nut’ (شركات 3) locks the screw in place. Incorrect lash is a primary cause of noise, فقدان الطاقة, و قطار صمام FAW J6P فشل.

This is the most advanced “منطق” في هذا قطار صمام FAW J6P, a feature essential for a heavy-duty dump truck. This is *not* an exhaust brake.

1. ال “Compression-Release” منطق:

ال “منطق” من أ “جيك بريك” is to turn the engine into an air compressor. When the brake is activated, a solenoid (غير مدرجة) sends high-pressure engine oil into the ‘Rocker shaft’ (شركات 12). This oil flows into the ‘Rocker arm-exhaust’ (شركات 8) and acts on the ‘Pressure valve-rocker arm’ (شركات 17). هذا “المنطق الهيدروليكي” opens the valve, which pushes on a “slave piston” inside the rocker arm. This slave piston then *opens the exhaust valve* near the top of the compression stroke. This instantly releases all the compressed air, forcing the engine to “يضيع” its power. وهذا يخلق قوية, 200+ hp braking effect, saving the wheel brakes.

2. عناصر: ‘Pressure valve’ (1007117-29د), ‘Ball seat’ (1007118-29د), & ‘Limit pin’ (1007103-29د)

هذا هو “الضغط العالي” الجمعية الفرعية. The ‘Pressure valve’ (شركات 17) is the hydraulic “مشغل.” The ‘Ball seat’ (شركات 18) is the pivot for the valve-actuating part of the rocker. The ‘Limit pin’ (شركات 7) هو “قف” that controls the travel of the engine brake mechanism. This entire system is what separates a standard قطار صمام FAW J6P from a “الثقيلة” قطار صمام FAW J6P.

This group of components is located *inside* the cylinder head, but they are all critical, serviceable parts of the قطار صمام FAW J6P.

1. عناصر: ‘Intake valve seat’ (1007016-36د) & ‘Exhaust valve seat’ (1003013-36د)

هذا هو “Combustion Sealing Logic.” The valves must seal against a perfectly round, incredibly hard surface. The cylinder head is too soft for this. ال “منطق” here is to press-fit two different types of ‘Valve seats’ (شركات 24 & 25) into the head. The ‘Exhaust valve seat’ (شركات 25) is made of a very hard, high-temperature steel alloy (like Stellite) to withstand superheated exhaust. The ‘Intake valve seat’ (شركات 24) is a different hardened steel, cooled by the intake air. هُم “منطق الخدمة” is that they are “ذبيحة” and can be re-ground or replaced.

2. عنصر: ‘Valve guide’ (1003014-29د)

هذا (شركات 23) هو “Precision Guide Logic.” القائمة تدعو إلى 24 أدلة (12 المدخول, 12 العادم). هُم “منطق” is to be a replaceable, low-friction sleeve (often bronze alloy) that is press-fit into the head. This guide is what holds the valve stem in perfect alignment as it moves up and down 15+ مرات في الثانية الواحدة. A worn valve guide will cause high oil consumption and poor valve sealing.

3. عنصر: ‘Valve guide oil seal assy’ (1007035-29د)

هذا (شركات 22) هو “Oil Control Logic.” This is a small, spring-loaded rubber seal that snaps onto the top of the valve guide. إنه “منطق” is to allow a *microscopic* film of oil to travel down the valve stem for lubrication, but to prevent the “bath” of oil splashing around the قطار صمام FAW J6P from being *sucked* into the engine on the intake stroke. Failed valve seals are a primary cause of blue smoke and oil consumption.

EXPLAIN:

هذه المجموعة النهائية “منطق” is to ensure the valves *close* quickly and completely, and to keep the entire assembly locked together at high RPM.

1. عنصر: ‘Exhaust valve spring’ (1007022-29د)

هذا (شركات 21) هو “Closing Force Logic.” القائمة تدعو إلى 12, one for each exhaust valve (intake springs are not on this list, but are similar). ال “منطق” of this heavy-duty spring is to provide enough force to slam the valve shut against the high-pressure exhaust gas, perfectly sealing the cylinder. It must also be “ضبطها” to the correct frequency to prevent “valve float”—a condition at high RPM where the spring can’t keep up and the valve fails to close, leading to a collision with the piston.

2. عنصر: ‘Valve spring seat’ (1007024-29د)

هذا (شركات 20) هو “Protection Logic.” القائمة تدعو إلى 24 (one for each valve). ال فاو J6P الاسطوانة is made of a softer metal (cast iron or aluminum). ال “منطق” of this hardened steel “seat” is to sit *between* the spring and the head, preventing the high-pressure spring from “chewing” أو “digging” its way into the head casting over millions of cycles.

3. عنصر: ‘Valve cotter’ (1007028-29د)

هذا (شركات 19) هو “Retention Logic.” القائمة تدعو إلى 48 (two for each valve). These are the two tiny, wedge-shaped “keepers” that lock into a groove at the top of the valve stem. ال “منطق” is that the spring’s force (pushing up on the retainer, غير مدرجة) forces these two cotters *together*, إنشاء أ “taper-lock” that holds the entire spring assembly onto the valve. These tiny parts are the only thing preventing the valve from dropping into the cylinder, which would destroy the entire قطار صمام FAW J6P والمحرك.

الجدول التالي يوفر كامل, تفصيل مفصل للجميع 25 أنواع المكونات في قطار صمام FAW J6P حَشد (مع فرامل المحرك) لفاو جيفانغ CA3250P66K2L1T1E 6×4 تفريغ الشاحنة.

| علامة | الجزء لا. | جزء اسم | كمية |

|---|---|---|---|

| 1 | س1820880 | الترباس شفة مسدس | 10 |

| 2 | 1007104-29د (1007104B29D) | Bolt-rocker shaft support | 1 M8x20 |

| 3 | 1007113-29د | Locking nut-valve adjusting screw | 12 |

| 4 | 1007121-29د | Rocker arm-intake | 6 |

| 5 | 1007112-29د | Adjusting screw-rocker arm | 12 |

| 6 | 1007114-29د (1007114A29D) | Bushing-rocker arm | 12 |

| 7 | 1007103-29د | Limit pin-rocker arm | 12 |

| 8 | 1007111-48د (1007111-621-0000) | Rocker arm-exhaust | 6 |

| 9 | 1007106-48د (1007106A621-0000) | Bolt-rocker shaft support | 4 |

| 10 | س1840835 | الترباس شفة مسدس | 5 |

| 11 | 1007102-29د | Rocker shaft support | 5 |

| 12 | 1007130-29د (1007130A29D) | Rocker shaft assy | 1 |

| 13 | GB/T71-1985 | Slotted countersunk head screw M8x20 | 1 |

| 14 | Q340B08T12 | Type I hexagon nut | 1 |

| 15 | 1007101-29د | Rocker shaft rear support | 1 |

| 16 | 1007117-29د | Pressure valve-rocker arm | 12 |

| 17 | 1007118-29د | Ball seat-rocker arm | 12 |

| 18 | 1007012-29د (1007012-29و) | Crosshead (قابلة للتبديل بالكامل) | 12 |

| 19 | 1007028-29د | صمام كوتر | 48 |

| 20 | 1007024-29د | Valve spring seat | 24 |

| 21 | 1007022-29د | Exhaust valve spring | 12 |

| 22 | 1007035-29د (1007035A29D) | Valve guide oil seal assy | 24 |

| 23 | 1003014-29د (1003014M29D) | Valve guide | 24 |

| 24 | 1003013-36د | مقعد صمام العادم | 12 |

| 25 | 1007016-36د | مقعد صمام السحب | 12 |

المواصفات ل قطار صمام FAW J6P are defined by its dual function as an OHV actuation system and a compression-release engine brake.

| تطبيق المركبة | فاو جيفانغ CA3250P66K2L1T1E 6×4 شاحنة قلابة |

| مجموعة النظام | قطار صمام FAW J6P / Valvetrain Assembly |

| نوع النظام | Overhead Valve (OHV) / Cam-in-Block |

| ميزة رئيسية | Integrated Compression-Release Engine Brake |

| منطق التشغيل | ‘Rocker shaft assy’ (1007130-29د) with ‘Rocker arms’ |

| Engine Brake Logic | ‘Pressure valve-rocker arm’ (1007117-29د) – الكمية 12 |

| Valve Control | ‘Crosshead’ (1007012-29د) – (For 4-valve-per-cylinder design) |

| Wear Component (Guide) | ‘Valve guide’ (1003014-29د) – الكمية 24 |

| Wear Component (ختم) | ‘Intake/Exhaust valve seat’ (1007016-36د / 1003013-36د) – الكمية 24 المجموع |

| Oil Control Logic | ‘Valve guide oil seal assy’ (1007035-29د) – الكمية 24 |

| منطق الاحتفاظ | ‘Valve cotter’ (1007028-29د) – الكمية 48 |

| النظام المرتبط | ممتلىء قطار صمام FAW J6P and Cylinder Head |

أجزاء فاو, بما في ذلك مجموعة كتلة الأسطوانة, يتم تعبئتها بعناية لضمان الولادة الآمنة. يتم تأمين كل مكون في مواد واقية لمنع الضرر أثناء النقل. تضمن الشبكة اللوجستية الشحنات في الوقت المناسب في جميع أنحاء العالم, دعم عمليات الصيانة الفعالة. فيما يلي صورة توضح العبوة القياسية لقطع غيار شاحنات FAW, إظهار الاهتمام بالتفاصيل في التعامل والتخزين.

يقلل أسلوب التغليف هذا من مخاطر التآكل أو التلف الناتج عن الصدمات, ضمان وصول أجزاء مثل FAW Cylinder Block Assembly في حالة ممتازة. يمكن للعملاء الاعتماد على الخدمات اللوجستية التي تقدمها FAW للحصول على الجودة والموثوقية المتسقة.