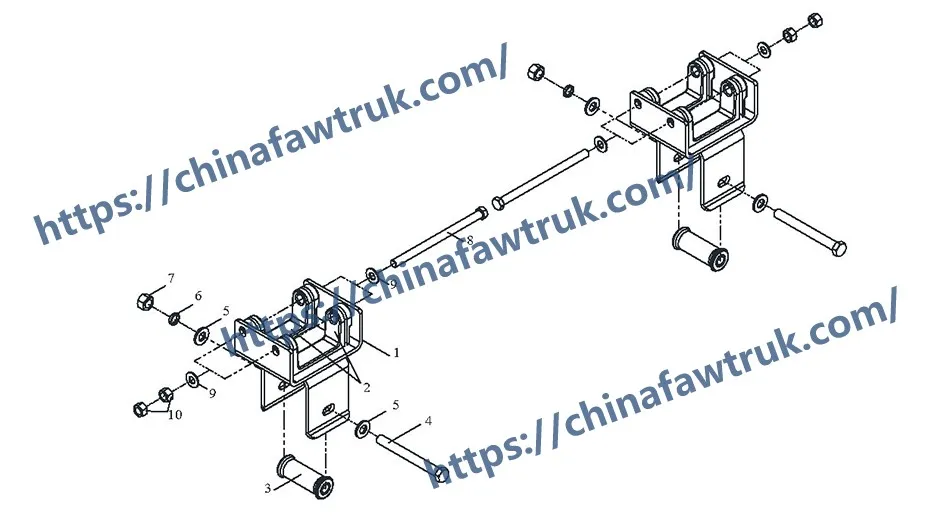

This is a comprehensive technical deconstruction of the Ensemble de suspension arrière pour cabine (Supérieur, Ressort hélicoïdal) Pour le FAW Jiefang CA3250P66K2L1T1E 6×4 tombereau. Ce guide analyse les 10 serviceable component types that form the critical rear damping system, isolating the cab from the severe longitudinal and vertical movements of the chassis.

Le Ensemble de suspension arrière pour cabine is essential for maintaining driver comfort and safety. As the cab pivots on the front mount (tilt point), this rear suspension provides the necessary dampening and vertical support. This specific design uses coil springs and hydraulic shock absorbers (dampers) to effectively absorb road shocks and engine vibrations, which are intensified by the heavy-duty chassis.

This deconstruction will analyze the key mechanical components of the Ensemble de suspension arrière pour cabine, including the mounting brackets, the damping system (likely integrated into Comp 1), and the associated high-strength fasteners. Maintaining the integrity of this assembly is vital, as any wear or failure here would lead to severe cab bounce and vibration, compromising driver control and potentially damaging in-cab electronic equipment. The proper function of the Ensemble de suspension arrière pour cabine ensures the vehicle remains reliable in demanding conditions.

This group contains the components that provide the actual spring force and motion control for the Ensemble de suspension arrière pour cabine. This is where the shock absorption occurs.

1. Composant: ‘Mounting bracket welding assy’ (5001430-A01) – Quantité 2

Ce (Comp 1) is the main structural bracket, likely the component that connects the cab structure to the shock absorber/spring assembly. C'est un véhicule robuste, welded assembly designed to anchor the entire vertical load of the cab’s rear section.

2. Composant: 'Bague – mounting bracket’ (5001434-A01) – Quantité 4

Ces (Comp 2) are high-density rubber or polyurethane bushings. Le Logique d'isolement est crucial: these bushings are inserted at the pivot points to prevent direct metal-on-metal contact, dampening high-frequency vibrations before they reach the driver. Worn bushings are the leading cause of excessive cab noise and movement in the Ensemble de suspension arrière pour cabine.

3. Composant: ‘Hydraulic damper pin’ (5001433-A01) – Quantité 2

Ce (Comp 3) is the hardened steel pin that connects the hydraulic damper (amortisseur) to the main cab bracket (Comp 1). Le Logique pivot requires this pin to be strong and precisely machined, as it serves as the pivot axis for the damper’s movement within the Ensemble de suspension arrière pour cabine.

This group includes the critical fasteners and mounting accessories that hold the Ensemble de suspension arrière pour cabine rigidly to the chassis and the cab structure.

1. Composant: ‘Hex head guide bolt’ (CQ15114130) – Quantité 2

Ce (Comp 4) is a specialized bolt with a shoulder or guide surface. Le Locating Logic is that this bolt helps center and align the assembly as it is tightened. This precision placement is key for the Ensemble de suspension arrière pour cabine to function without binding.

2. Composant: ‘Mounting bracket bolt’ (5001436-A01) – Quantité 4

Ce (Comp 8) is the main mounting hardware for the bracket assembly (Comp 1). These bolts secure the cab mount to the frame rail. They must be torqued to a precise specification to prevent structural failure in the Ensemble de suspension arrière pour cabine.

3. Composant: « Écrou hexagonal’ (CQ34114, CQ34112) & « Rondelle élastique’ (Q40314, Q40318)

Ce (Comp 5, 7, 10, 6) is the assortment of standard hardware used throughout the Ensemble de suspension arrière pour cabine. The combination of ‘Hex nut’ et « Rondelle élastique’ ensures the connections are resistant to loosening caused by the constant high-frequency vibration inherent in a dump truck. The integrity of the frame connection depends on this hardware.

4. Composant: 'Joint’ (Q40114, Q40112) – Quantité 4 et 8

Ces (Comp 5, 9) are plain washers or shims used to distribute the clamping force of the bolts and nuts. Their placement is critical, particularly under the high-stress areas of the Ensemble de suspension arrière pour cabine, protecting the metal surfaces of the brackets from being gouged by the spinning nut.

Le tableau suivant fournit l'intégralité, ventilation détaillée de tous 10 types de composants dans le Ensemble de suspension arrière pour cabine Pour le FAW Jiefang CA3250P66K2L1T1E 6×4 tombereau. Cette liste est indispensable pour commander des pièces de rechange et effectuer un service complet du Ensemble de suspension arrière pour cabine.

| Marque | Partie no. | Nom de la pièce | Quantité |

|---|---|---|---|

| 1 | 5001430-A01 | Mounting bracket welding assy | 2 |

| 2 | 5001434-A01 | Bague – mounting bracket | 4 |

| 3 | 5001433-A01 | Hydraulic damper pin | 2 |

| 4 | CQ15114130 | Boulon de guidage à tête hexagonale | 2 |

| 5 | Q40114 | Joint | 4 |

| 6 | Q40314 | Rondelle élastique | 2 |

| 7 | CQ34114 | Écrou hexagonal | 2 |

| 8 | 5001436-A01 | Mounting bracket bolt | 4 |

| 9 | Q40112 | Joint | 8 |

| 10 | CQ34112 | Écrou hexagonal | 4 |

Les spécifications pour le Ensemble de suspension arrière pour cabine are defined by its function as a high-strength, dampening mount for the rear of the tilt-cab. This assembly is crucial for vertical shock isolation.

| Demande de véhicule | FAW Jiefang CA3250P66K2L1T1E 6×4 Tombereau |

| Groupe système | Ensemble de suspension arrière pour cabine |

| Logique primaire | Vertical shock isolation using dampers/coil springs (implicite) |

| Core Component P/N | 5001430-A01 (Mounting bracket welding assy) |

| Damping Pin P/N | 5001433-A01 |

| Pivot/Isolation | Bague (5001434-A01) and hydraulic pivot (épingle) |

| Safety Component | ‘Shock absorber limit block’ (5001021-A01) |

| Matériel de montage | High-strength bolts (5001436-A01) and CQ series nuts/washers |

| Types de composants totaux | 10 |

| Système associé | Cab Suspension / Châssis. Le Ensemble de suspension arrière pour cabine is the rear anchor. |

Pièces FAW, y compris l'ensemble bloc-cylindres, sont emballés avec soin pour garantir une livraison en toute sécurité. Chaque composant est sécurisé dans des matériaux de protection pour éviter tout dommage pendant le transport. Le réseau logistique garantit des expéditions ponctuelles dans le monde entier, soutenir des opérations de maintenance efficaces. Vous trouverez ci-dessous une image illustrant l'emballage standard des pièces de camion FAW., mettant en valeur l’attention portée aux détails dans la manipulation et le stockage.

Cette approche d'emballage minimise le risque de corrosion ou de dommages causés par les chocs., s'assurer que les pièces comme l'ensemble bloc-cylindres FAW arrivent en parfait état. Les clients peuvent compter sur la logistique de FAW pour une qualité et une fiabilité constantes.