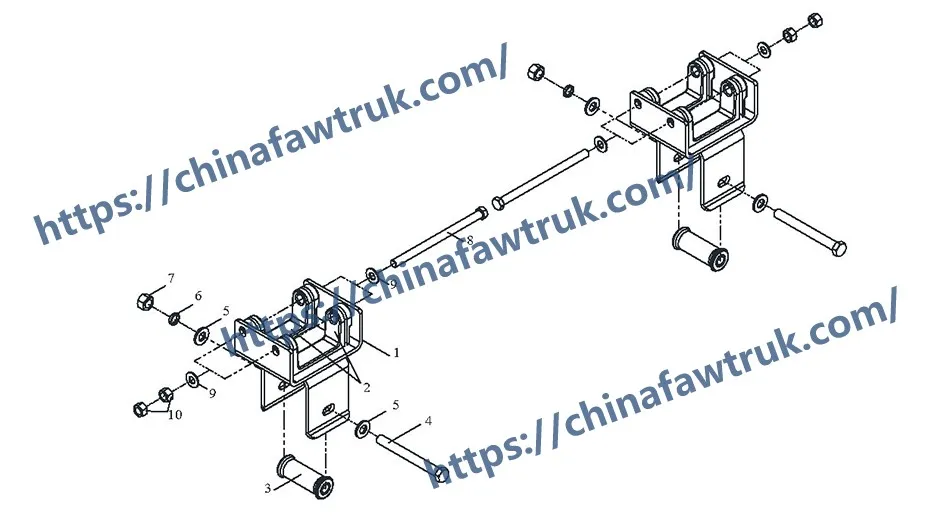

This is a comprehensive technical deconstruction of the Conjunto de suspensão traseira para cabine (Superior, Mola helicoidal) para o FAW Jiefang CA3250P66K2L1T1E 6×4 caminhão despejando. Este guia analisa o 10 serviceable component types that form the critical rear damping system, isolating the cab from the severe longitudinal and vertical movements of the chassis.

O Conjunto de suspensão traseira para cabine is essential for maintaining driver comfort and safety. As the cab pivots on the front mount (tilt point), this rear suspension provides the necessary dampening and vertical support. This specific design uses coil springs and hydraulic shock absorbers (dampers) to effectively absorb road shocks and engine vibrations, which are intensified by the heavy-duty chassis.

This deconstruction will analyze the key mechanical components of the Conjunto de suspensão traseira para cabine, including the mounting brackets, the damping system (likely integrated into Comp 1), and the associated high-strength fasteners. Maintaining the integrity of this assembly is vital, as any wear or failure here would lead to severe cab bounce and vibration, compromising driver control and potentially damaging in-cab electronic equipment. A função adequada do Conjunto de suspensão traseira para cabine ensures the vehicle remains reliable in demanding conditions.

This group contains the components that provide the actual spring force and motion control for the Conjunto de suspensão traseira para cabine. This is where the shock absorption occurs.

1. Componente: ‘Mounting bracket welding assy’ (5001430-A01) – Quantidade 2

Esse (Comp. 1) is the main structural bracket, likely the component that connects the cab structure to the shock absorber/spring assembly. É um serviço pesado, welded assembly designed to anchor the entire vertical load of the cab’s rear section.

2. Componente: 'Casquilho – mounting bracket’ (5001434-A01) – Quantidade 4

Esses (Comp. 2) are high-density rubber or polyurethane bushings. O Lógica de Isolamento é crucial: these bushings are inserted at the pivot points to prevent direct metal-on-metal contact, dampening high-frequency vibrations before they reach the driver. Worn bushings are the leading cause of excessive cab noise and movement in the Conjunto de suspensão traseira para cabine.

3. Componente: ‘Hydraulic damper pin’ (5001433-A01) – Quantidade 2

Esse (Comp. 3) é o pino de aço endurecido que conecta o amortecedor hidráulico (amortecedor) to the main cab bracket (Comp. 1). O Lógica dinâmica requires this pin to be strong and precisely machined, as it serves as the pivot axis for the damper’s movement within the Conjunto de suspensão traseira para cabine.

This group includes the critical fasteners and mounting accessories that hold the Conjunto de suspensão traseira para cabine rigidly to the chassis and the cab structure.

1. Componente: ‘Hex head guide bolt’ (CQ15114130) – Quantidade 2

Esse (Comp. 4) is a specialized bolt with a shoulder or guide surface. O Locating Logic is that this bolt helps center and align the assembly as it is tightened. This precision placement is key for the Conjunto de suspensão traseira para cabine to function without binding.

2. Componente: ‘Mounting bracket bolt’ (5001436-A01) – Quantidade 4

Esse (Comp. 8) is the main mounting hardware for the bracket assembly (Comp. 1). These bolts secure the cab mount to the frame rail. They must be torqued to a precise specification to prevent structural failure in the Conjunto de suspensão traseira para cabine.

3. Componente: 'Porca sextavada’ (CQ34114, CQ34112) & ‘Arruela de pressão’ (Q40314, Q40318)

Esse (Comp. 5, 7, 10, 6) is the assortment of standard hardware used throughout the Conjunto de suspensão traseira para cabine. The combination of ‘Hex nut’ and ‘Spring washer’ ensures the connections are resistant to loosening caused by the constant high-frequency vibration inherent in a dump truck. The integrity of the frame connection depends on this hardware.

4. Componente: 'Junta’ (Q40114, Q40112) – Quantidade 4 e 8

Esses (Comp. 5, 9) are plain washers or shims used to distribute the clamping force of the bolts and nuts. Their placement is critical, particularly under the high-stress areas of the Conjunto de suspensão traseira para cabine, protecting the metal surfaces of the brackets from being gouged by the spinning nut.

A tabela a seguir fornece o completo, detalhamento de todos 10 tipos de componentes no Conjunto de suspensão traseira para cabine para o FAW Jiefang CA3250P66K2L1T1E 6×4 caminhão despejando. Esta lista é essencial para solicitar peças de reposição e realizar um serviço completo do Conjunto de suspensão traseira para cabine.

| Marca | Parte não. | Nome da peça | Quantidade |

|---|---|---|---|

| 1 | 5001430-A01 | Mounting bracket welding assy | 2 |

| 2 | 5001434-A01 | Casquilho – mounting bracket | 4 |

| 3 | 5001433-A01 | Hydraulic damper pin | 2 |

| 4 | CQ15114130 | Parafuso guia de cabeça sextavada | 2 |

| 5 | Q40114 | Junta | 4 |

| 6 | Q40314 | Arruela elástica | 2 |

| 7 | CQ34114 | Noz hexadecimal | 2 |

| 8 | 5001436-A01 | Mounting bracket bolt | 4 |

| 9 | Q40112 | Junta | 8 |

| 10 | CQ34112 | Noz hexadecimal | 4 |

As especificações para o Conjunto de suspensão traseira para cabine são definidos por sua função como um produto de alta resistência, dampening mount for the rear of the tilt-cab. Esta montagem é crucial para o isolamento de choque vertical.

| Aplicação em veículos | FAW Jiefang CA3250P66K2L1T1E 6×4 Caminhão basculante |

| Grupo de sistemas | Conjunto de suspensão traseira para cabine |

| Lógica Primária | Vertical shock isolation using dampers/coil springs (implícito) |

| Componente principal P/N | 5001430-A01 (Mounting bracket welding assy) |

| Pino de amortecimento P/N | 5001433-A01 |

| Pivot/Isolation | Casquilho (5001434-A01) and hydraulic pivot (alfinete) |

| Componente de segurança | ‘Shock absorber limit block’ (5001021-A01) |

| Hardware de montagem | High-strength bolts (5001436-A01) and CQ series nuts/washers |

| Total de tipos de componentes | 10 |

| Sistema Associado | Suspensão da cabine / Chassis. O Conjunto de suspensão traseira para cabine is the rear anchor. |

Peças FAW, incluindo o conjunto do bloco de cilindros, são embalados com cuidado para garantir uma entrega segura. Cada componente é protegido por materiais de proteção para evitar danos durante o transporte. A rede logística garante envios pontuais em todo o mundo, apoiando operações de manutenção eficientes. Abaixo está uma imagem ilustrando a embalagem padrão para peças de caminhão FAW, mostrando a atenção aos detalhes no manuseio e armazenamento.

Esta abordagem de embalagem minimiza o risco de corrosão ou danos por impacto, garantindo que peças como o conjunto do bloco de cilindros FAW cheguem em perfeitas condições. Os clientes podem confiar na logística da FAW para obter qualidade e confiabilidade consistentes.