Il s'agit d'une déconstruction technique complète du Bouchon de remplissage d'eau FAW J6P assemblée (Chapitre 38). Ce composant, also known as the ‘Pressure cap assy’ (Comp 1), is the most critical “Smallest Serviceable Unit” for the entire cooling system on the FAW Jiefang CA3250P66K2L1T1E 6×4 tombereau. It is not a simple “capuchon”; it is an active “safety valve” et le “cerveau” of the system’s physics.

Le Bouchon de remplissage d'eau FAW J6P a un “Dual-Valve Logic” that is essential for preventing engine damage. C'est le premier “logique” est “Pressurization.” By sealing the system and holding pressure (Par exemple, 15 psi), il “raises the boiling point” of the coolant from 100°C to ~120°C, empêcher “flash boiling” in the hot cylinder heads.

C'est la deuxième “logique” est “Vacuum Relief.” Quand le moteur refroidit, the coolant contracts, creating a powerful vacuum. Le Bouchon de remplissage d'eau FAW J6P has a secondary valve that “opens” to allow coolant/air *in* from the ‘Expansion tank’ (Comp 2), preventing this vacuum from “collapsing” and destroying the radiator hoses.

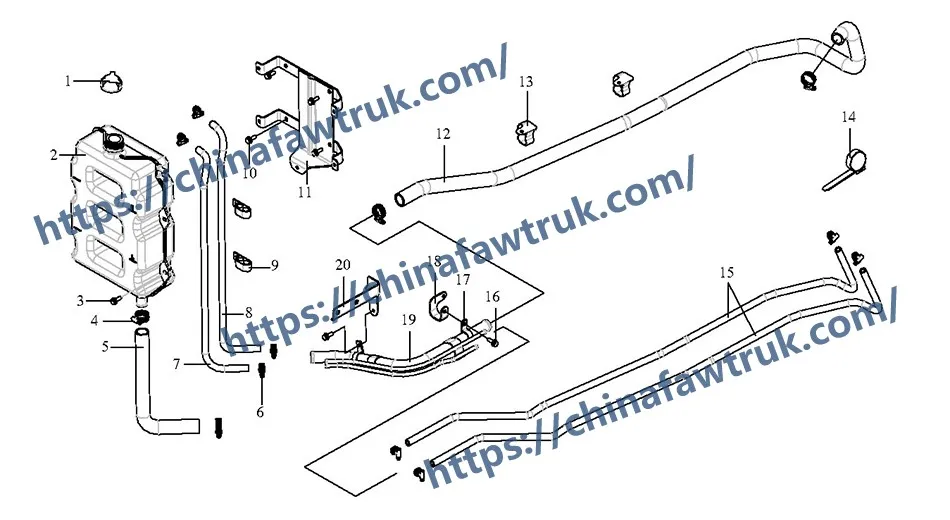

This guide is a vital resource for all technicians, as a failed Bouchon de remplissage d'eau FAW J6P is often misdiagnosed as a “major” overheating problem. We will deconstruct all 20 parts in this assembly, analyser le “Logique de pression” (the cap itself), le “Reservoir Logic” (the tank it sits on), le “Plumbing Logic” (the hoses it controls), et le “Logique de montage” (the brackets that secure it).

This component *is* the Bouchon de remplissage d'eau FAW J6P. It is the single most important component in this entire assembly for regulating the physics of the cooling system.

1. Composant: ‘Pressure cap assy’ (1304010-50UN)

Ce (Comp 1) est le “Boiling Point Logic.” A heavy-duty diesel engine (like the one in the FAW J6P) operates under such high load that its coolant temperature often exceeds the 100°C (212° F) boiling point of water (at sea level).

Le Bouchon de remplissage d'eau FAW J6P est un “spring-loaded” soupape. Il “scellés” the ‘Expansion tank assy’ (Comp 2) and the entire cooling system, allowing pressure to build up. Ce “Pressurization Logic” (Par exemple, à 1.0 bar / 15 psi) “tricks” the coolant, raising its boiling point to ~120°C (~250°F).

Ce “Anti-Boil Logic” is what prevents “flash boiling” ou “steam pockets” from forming in the cylinder head, which would immediately stop heat transfer and cause the aluminum head to warp or crack.

Le “Dual-Valve Logic” of the FAW J6P Water Filler Cap:

1. Main Pressure Valve (Outward): C'est le “Safety Logic.” A large spring holds this valve shut (Par exemple, à 15 psi). If the pressure gets *too high* (Par exemple, from a failing head gasket), this valve “vents” the excess pressure *out*, empêcher le “FAW J6P Radiateur” (Chapitre 37) or hoses from exploding.

2. Vacuum Relief Valve (Inward): C'est le “Implosion-Proof Logic.” When the engine is shut off, the 90°C coolant cools and “contracts,” creating a powerful “vacuum.” Ce “vacuum” would “suck” the ‘Radiator outlet hose’ (Chapitre 37) completely flat, “imploding” il. Le Bouchon de remplissage d'eau FAW J6P has a second, smaller, “inward” valve that “opens” under this vacuum, drawing coolant *back in* from the ‘Expansion tank’ (Comp 2) to keep the system full and at neutral pressure.

Le Bouchon de remplissage d'eau FAW J6P (Comp 1) does not mount to the radiator. It mounts to this component, the ‘Expansion tank assy’.

1. Composant: ‘Expansion tank assy’ (1311020-76UN)

Ce (Comp 2) est le “Reservoir Logic” et le “Air-Trap Logic.” C'est le “poumon” of the cooling system. C'est “logique” est de fournir le “empty space” (de la “MIN” à “MAX” doubler) that the expanding, hot coolant needs to “flow into.”

This is also the “Degassing Logic” centre. All the small “degas” tuyaux (Comp 7, 8, 15) from the engine and radiator “terminate” ici. Ils “décharge” air bubbles into this tank, where internal baffles “séparé” the air from the coolant.

Le “Symbiotic Logic” est-ce que c'est le Bouchon de remplissage d'eau FAW J6P (Comp 1) *must* be at the “highest point” du système, which is this tank. Cela permet au “scavenged” air to be vented *out* of the system by the ‘Pressure cap’ when needed. Ce “cap-on-tank” design is the “Active Thermal Management” logic of the entire FAW J6P cooling system.

This group represents all the “Les plus petites unités utilisables” (SSU) que “feed” the expansion tank that the Bouchon de remplissage d'eau FAW J6P controls.

1. Le “Degas & Return” Logique (Tuyaux & Tuyaux)

This network of “plomberie” est le “arterial system” for the tank. It includes the ‘Degas hose’ (Comp 7, 8, 15) et le ‘Return water hose’ (Comp 5, 12). Ce “logique” est de “transport” the air and coolant to/from the ‘Expansion tank’ (Comp 2).

2. Le “Scellage” Logique (Pinces)

C'est le “Leak-Proof Logic.” Il comprend ‘Banjo-type hose clamp B model’ (Comp 4, 6), « Collier de serrage’ (Comp 13), et ‘Single pipe clamp’ (Comp 17). Le “Banjo-type” (T-Bolt) clamps are the “couple élevé” pinces. A single failed clamp (Par exemple, Comp 6) means a “catastrophic coolant loss.”

3. Le “Anti-frottement” Logique (Pinces & Ties)

C'est le “Vibration-Proofing Logic.” It includes the ‘Dual pipe clamp assy’ (Comp 9) et le ‘Plastic zip tie’ (T67420376) (Comp 14).

The six (6) « Attaches zippées en plastique’ (Comp 14) sont “Deliberate Engineering Logic.” Leur “logique” est de “ancre” the small, flexible ‘Degas hoses’ (Comp 7, 8, 15) au châssis, preventing them from “friction” (rubbing) against the vibrating engine. UN “chafed” hose will leak, drain the system, and render the Bouchon de remplissage d'eau FAW J6P‘s function useless, conduisant à une surchauffe.

This final group provides the “contexte” pour le Bouchon de remplissage d'eau FAW J6P. The cap must be accessible to the driver and “isolated” from vibration.

1. Le “Soutien” Logique (Composants 11, 18, 20)

Le ‘Expansion tank bracket assy’ (1311040-61C) (Comp 11), ‘Bracket assy’ (1311070-14B) (Comp 18), et ‘Bracket assy’ (1311075-14B) (Comp 20) form the “structural cage” for the ‘Expansion tank’ (Comp 2).

Ce “Logique de montage” c'est quoi “écluses” the polymer tank (et le Bouchon de remplissage d'eau FAW J6P on top of it) to the rigid steel chassis of the dump truck, empêcher “fatigue cracks” from vibration.

2. Le “Attache” Logique (Composants 3, 10, 16)

Le « Boulon combiné’ (CQ1460825) est le “Hardware Logic.” A total of eleven (11) de ces boulons (5 + 4 + 2) are used to “sécurisé” these brackets to the frame. Ces “à bride” (autobloquant) les boulons sont “Logique résistante aux vibrations,” ensuring the entire assembly (réservoir, capuchon, and all) never rattles loose.

Le tableau suivant fournit l'intégralité, ventilation détaillée de tous 20 types de composants dans le Bouchon de remplissage d'eau FAW J6P and expansion tank assembly (Chapitre 38) Pour le FAW Jiefang CA3250P66K2L1T1E 6×4 tombereau.

| Marque | Partie no. | Nom de la pièce | Quantité |

|---|---|---|---|

| 1 | 1304010-50UN | Pressure cap assy | 1 |

| 2 | 1311020-76UN | Expansion tank assy | 1 |

| 3 | CQ1460825 | Boulon combiné | 5 |

| 4 | CQ67640B | Banjo-type hose clamp B model | 4 |

| 5 | 1311033-61B | Rear return water hose | 1 |

| 6 | CQ67622B | Banjo-type hose clamp B model | 8 |

| 7 | 1311068-61B | Degas hose | 1 |

| 8 | 1311069-61B | Rear degas hose | 1 |

| 9 | 1311060-61B | Dual pipe clamp assy | 2 |

| 10 | CQ1460825 | Boulon combiné | 4 |

| 11 | 1311040-61C | Expansion tank bracket assy | 1 |

| 12 | 1311033-14B | Return water hose | 1 |

| 13 | 1311077-61B | Collier de serrage | 2 |

| 14 | T67420376 | Plastic zip tie | 6 |

| 15 | 1311036-14B | Degas hose | 2 |

| 16 | CQ1460825 | Boulon combiné | 2 |

| 17 | 1311071A377 | Collier de serrage simple | 2 |

| 18 | 1311070-14B | Bracket assy | 1 |

| 19 | 1311065-14B | Rear return water steel pipe assy | 1 |

| 20 | 1311075-14B | Bracket assy | 1 |

Les spécifications pour le Bouchon de remplissage d'eau FAW J6P system are defined by its function as the active pressure and vacuum regulator for the entire cooling circuit.

| Demande de véhicule | FAW Jiefang CA3250P66K2L1T1E 6×4 Tombereau |

| Groupe système | Bouchon de remplissage d'eau FAW J6P & Ensemble vase d'expansion |

| Logique primaire | System Pressurization (Boiling Point Elevation) |

| Logique secondaire | Vacuum Relief (Anti-Collapse) & Pressure Venting (Sécurité) |

| Composant principal | ‘Pressure cap assy’ (1304010-50UN) |

| Associated Reservoir | ‘Expansion tank assy’ (1311020-76UN) |

| Degas Plumbing | 1311068-61B, 1311069-61B, 1311036-14B |

| Sealing Hardware | Banjo-type Clamps (CQ67640B, CQ67622B) |

| Anti-Chafe Hardware | ‘Plastic zip tie’ (T67420376) – Quantité 6 |

| Matériel de montage | ‘Expansion tank bracket assy’ (1311040-61C) |

Pièces FAW, y compris l'ensemble bloc-cylindres, sont emballés avec soin pour garantir une livraison en toute sécurité. Chaque composant est sécurisé dans des matériaux de protection pour éviter tout dommage pendant le transport. Le réseau logistique garantit des expéditions ponctuelles dans le monde entier, soutenir des opérations de maintenance efficaces. Vous trouverez ci-dessous une image illustrant l'emballage standard des pièces de camion FAW., mettant en valeur l’attention portée aux détails dans la manipulation et le stockage.

Cette approche d'emballage minimise le risque de corrosion ou de dommages causés par les chocs., s'assurer que les pièces comme l'ensemble bloc-cylindres FAW arrivent en parfait état. Les clients peuvent compter sur la logistique de FAW pour une qualité et une fiabilité constantes.