This is a technical deep-dive into the Vase d'expansion FAW J6P assemblée (Chapitre 38), le “poumon” of the cooling system for the FAW Jiefang CA3250P66K2L1T1E 6×4 tombereau. This is not a passive “overflow” bottle; it is an active, “double logique” composant. Il fournit “Thermal Expansion Logic” (managing coolant volume) et “Degassing Logic” (removing air), which is essential for protecting the engine.

Le “Thermal Expansion Logic” est sa fonction première. As coolant heats up, it expands in volume. Le Vase d'expansion FAW J6P provides a “safe-zone” for this hot, expanded coolant, preventing pressure from blowing out seals or cracking the radiator. As the engine cools, il “draws back” this coolant, keeping the system 100% full.

Le “Degassing Logic” is its most critical safety function. Air is the #1 enemy of a cooling system. Air bubbles cause “steam pockets” (conduisant à une surchauffe) et “cavitation” (which erodes the water pump). Le Vase d'expansion FAW J6P acts as the central “air-trap,” allowing scavenged air bubbles to be separated from the coolant and vented safely.

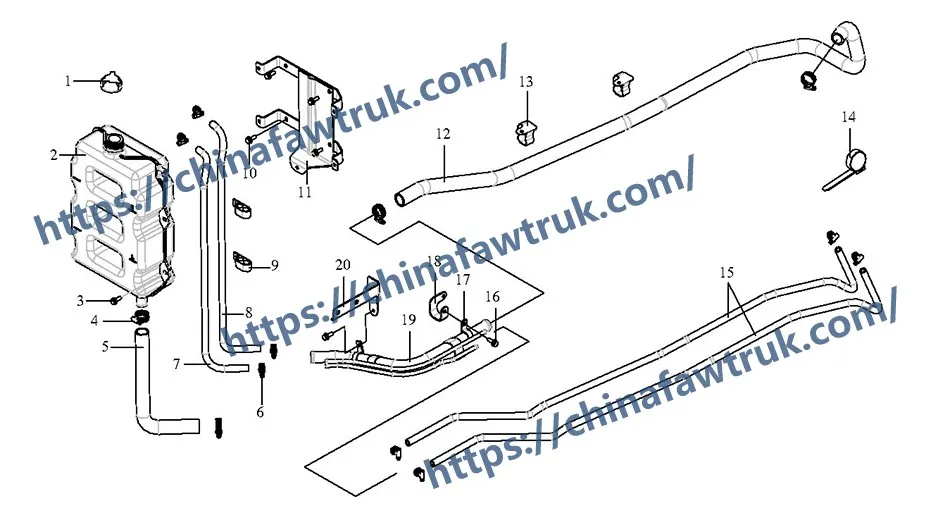

This guide is a vital resource for chassis technicians and parts specialists. We will deconstruct all 20 composants, analyser le “Core Logic” (the tank and pressure cap), le “Plomberie & Degassing Logic” (the network of hoses and pipes), et le “Montage & Logique anti-frottement” (the brackets, pinces, and zip ties that ensure long-term, vibration-proof integrity).

Ce groupe représente le “cœur” de la Vase d'expansion FAW J6P système. These two parts work together to control the physics of the entire cooling circuit.

1. Composant: ‘Expansion tank assy’ (1311020-76UN)

Ce (Comp 2) est le principal “Reservoir Logic.” C'est le Vase d'expansion FAW J6P lui-même. C'est un “flow-through” réservoir, not a “dead-end” overflow. Coolant and scavenged air are constantly flowing *through* it.

Made from a “heat-stabilized polymer,” c'est “Thermal Buffer Logic” allows it to safely hold expanding, 90°C+ coolant. Interne “chicanes” (not visible) help “séparé” the air bubbles from the liquid coolant, allowing the air to rise to the top while the air-free coolant is drawn from the bottom. Le “MIN/MAX” lines on its side are a critical daily check for technicians.

2. Composant: ‘Pressure cap assy’ (1304010-50UN)

Ce (Comp 1) est le “Boiling Point Logic” and the system’s “Safety Valve.” A modern diesel engine runs *above* the normal 100°C (212° F) boiling point of water. This cap “scellés” le système.

C'est “Pressurization Logic” (Par exemple, holding 1.0 bar / 15 psi) raises the coolant’s boiling point to ~120°C (~250°F), empêcher “flash boiling” inside the engine head. This cap is a “dual-action” soupape:

Pressure Valve (Out): If pressure exceeds 15 psi (Par exemple, from a head gasket leak), a spring-loaded valve opens, venting pressure *out* to prevent the radiator or hoses from bursting.

Vacuum Valve (Dans): Quand le moteur refroidit, the coolant contracts, créer un “vacuum.” A second, smaller valve opens to allow air/coolant *in*, preventing the ‘Radiator outlet hose’ (Chapitre 37) depuis “collapsing” under suction.

Ce groupe est le “réseau artériel” qui relie le Vase d'expansion FAW J6P to the engine and radiator. C'est “logique” is to move both “air” et “coolant.”

1. Le “Air Scavenger” Logique (Composants 7, 8, 15)

C'est le “Air-Free Logic” réseau. Il comprend ‘Degas hose’ (1311068-61B) (Comp 7), ‘Rear degas hose’ (1311069-61B) (Comp 8), et ‘Degas hose’ (1311036-14B) (Comp 15).

These small-bore hoses connect to the *highest points* of the cooling system (like the top of the ‘Radiator assy’, Chapitre 37). Leur “Scavenging Logic” is to continuously “saigner” any trapped air bubbles *away* from the engine and *to* the Vase d'expansion FAW J6P, where they are safely separated.

2. Le “Coolant Return” Logique (Composants 5, 12, 19)

C'est le “Plumbing Logic.” Il comprend ‘Rear return water hose’ (1311033-61B) (Comp 5), ‘Return water hose’ (1311033-14B) (Comp 12), et le ‘Rear return water steel pipe assy’ (1311065-14B) (Comp 19).

This network’s “logique” is to take the now “de-aerated” coolant from the bottom of the Vase d'expansion FAW J6P et “retour” it to the “froid” ou “succion” side of the cooling system (Par exemple, near the water pump). This ensures the water pump only ever receives a 100% solide, air-free “charge” of coolant, empêcher “cavitation” dommage.

Ce groupe représente le “Les plus petites unités utilisables” (SSU) that are essential for the survival of the Vase d'expansion FAW J6P in a high-vibration dump truck environment.

1. Le “Montage structurel” Logique (Composants 11, 18, 20)

This group forms the “Vibration Isolation Logic.” Le ‘Expansion tank bracket assy’ (1311040-61C) (Comp 11), ‘Bracket assy’ (1311070-14B) (Comp 18), et ‘Bracket assy’ (1311075-14B) (Comp 20) create a rigid “steel cage.” Ce “cage” bolts to the chassis frame and securely holds the “polymère” Vase d'expansion FAW J6P (Comp 2), isolating it from the worst of the chassis “fléchir” and engine vibration.

2. Le “Scellage” Logique (Composants 4, 6, 13)

C'est le “Leak-Proof Logic.” Le ‘Banjo-type hose clamp B model’ (CQ67640B, CQ67622B) (Comp 4, 6) et « Collier de serrage’ (1311077-61B) (Comp 13) are the most critical SSUs.

Le “Banjo-type” (T-Bolt) clamps provide 360-degree, couple élevé “force de serrage” on the main hoses. UN “worm-gear” clamp would loosen under vibration. A failure of a single clamp (Par exemple, Comp 6) means a “catastrophic coolant loss” and engine seizure.

3. Le “Anti-frottement” Logique (Composants 9, 14, 17)

C'est le “Routing Protection Logic.” Ce groupe comprend ‘Dual pipe clamp assy’ (1311060-61B) (Comp 9), ‘Plastic zip tie’ (T67420376) (Comp 14), et ‘Single pipe clamp’ (1311071A377) (Comp 17).

Le “logique” of these parts is to “ancre” the flexible degas hoses (Comp 7, 8, 15). Le #1 killer of hoses is “friction” (rubbing against a sharp metal bracket or hot engine part). The six ‘Plastic zip ties’ (Comp 14) are not a “fix”; ils sont “Deliberate Engineering Logic” to secure these lines, ensuring they never rub or vibrate, guaranteeing the integrity of the Vase d'expansion FAW J6P‘s plumbing.

4. Le “Attache” Logique (Composants 3, 10, 16)

Le « Boulon combiné’ (CQ1460825) est le “Hardware Logic.” Ces 11 boulons (5 + 4 + 2) are used to “sécurisé” the brackets (Comp 11, 18, 20) au châssis du camion, completing the mounting system.

Le tableau suivant fournit l'intégralité, ventilation détaillée de tous 20 types de composants dans le Vase d'expansion FAW J6P assemblée (Chapitre 38) Pour le FAW Jiefang CA3250P66K2L1T1E 6×4 tombereau.

| Marque | Partie no. | Nom de la pièce | Quantité |

|---|---|---|---|

| 1 | 1304010-50UN | Pressure cap assy | 1 |

| 2 | 1311020-76UN | Expansion tank assy | 1 |

| 3 | CQ1460825 | Boulon combiné | 5 |

| 4 | CQ67640B | Banjo-type hose clamp B model | 4 |

| 5 | 1311033-61B | Rear return water hose | 1 |

| 6 | CQ67622B | Banjo-type hose clamp B model | 8 |

| 7 | 1311068-61B | Degas hose | 1 |

| 8 | 1311069-61B | Rear degas hose | 1 |

| 9 | 1311060-61B | Dual pipe clamp assy | 2 |

| 10 | CQ1460825 | Boulon combiné | 4 |

| 11 | 1311040-61C | Expansion tank bracket assy | 1 |

| 12 | 1311033-14B | Return water hose | 1 |

| 13 | 1311077-61B | Collier de serrage | 2 |

| 14 | T67420376 | Plastic zip tie | 6 |

| 15 | 1311036-14B | Degas hose | 2 |

| 16 | CQ1460825 | Boulon combiné | 2 |

| 17 | 1311071A377 | Collier de serrage simple | 2 |

| 18 | 1311070-14B | Bracket assy | 1 |

| 19 | 1311065-14B | Rear return water steel pipe assy | 1 |

| 20 | 1311075-14B | Bracket assy | 1 |

Les spécifications pour le Vase d'expansion FAW J6P system are defined by its dual function of managing coolant volume and actively degassing the engine.

| Demande de véhicule | FAW Jiefang CA3250P66K2L1T1E 6×4 Tombereau |

| Groupe système | Vase d'expansion FAW J6P, Plomberie & Montage |

| Logique primaire | Thermal Expansion Compensation & System Pressurization |

| Logique secondaire | Continuous Air Degassing & Scavenging |

| Core Tank Assembly | ‘Expansion tank assy’ (1311020-76UN) |

| Pressure Control | ‘Pressure cap assy’ (1304010-50UN) |

| Degas Hoses (Scavengers) | 1311068-61B, 1311069-61B, 1311036-14B |

| Return Hoses/Pipes (Feed) | 1311033-61B, 1311033-14B, 1311065-14B |

| Core Mounting Hardware | ‘Expansion tank bracket assy’ (1311040-61C) |

| Anti-Chafe Hardware | ‘Plastic zip tie’ (T67420376) – Quantité 6, ‘Dual pipe clamp’ (1311060-61B) |

Pièces FAW, y compris l'ensemble bloc-cylindres, sont emballés avec soin pour garantir une livraison en toute sécurité. Chaque composant est sécurisé dans des matériaux de protection pour éviter tout dommage pendant le transport. Le réseau logistique garantit des expéditions ponctuelles dans le monde entier, soutenir des opérations de maintenance efficaces. Vous trouverez ci-dessous une image illustrant l'emballage standard des pièces de camion FAW., mettant en valeur l’attention portée aux détails dans la manipulation et le stockage.

Cette approche d'emballage minimise le risque de corrosion ou de dommages causés par les chocs., s'assurer que les pièces comme l'ensemble bloc-cylindres FAW arrivent en parfait état. Les clients peuvent compter sur la logistique de FAW pour une qualité et une fiabilité constantes.