This is a technical deep-dive into the Tanque de expansão FAW J6P conjunto (Capítulo 38), o “pulmão” of the cooling system for the FAW Jiefang CA3250P66K2L1T1E 6×4 caminhão despejando. This is not a passive “overflow” bottle; it is an active, “lógica dupla” componente. Fornece “Thermal Expansion Logic” (managing coolant volume) e “Degassing Logic” (removing air), which is essential for protecting the engine.

O “Thermal Expansion Logic” é sua função principal. As coolant heats up, it expands in volume. O Tanque de expansão FAW J6P provides a “safe-zone” for this hot, expanded coolant, preventing pressure from blowing out seals or cracking the radiator. As the engine cools, isto “draws back” this coolant, keeping the system 100% full.

O “Degassing Logic” is its most critical safety function. Air is the #1 enemy of a cooling system. Air bubbles cause “steam pockets” (levando ao superaquecimento) e “cavitação” (which erodes the water pump). O Tanque de expansão FAW J6P acts as the central “air-trap,” allowing scavenged air bubbles to be separated from the coolant and vented safely.

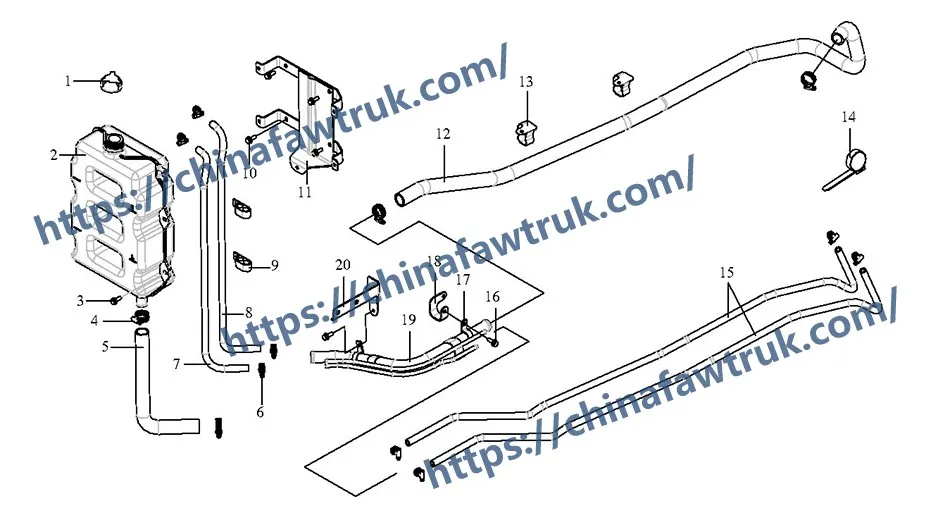

This guide is a vital resource for chassis technicians and parts specialists. We will deconstruct all 20 componentes, analisando o “Lógica Central” (the tank and pressure cap), o “Encanamento & Degassing Logic” (the network of hoses and pipes), e o “Montagem & Anti-Chafe Logic” (the brackets, braçadeiras, and zip ties that ensure long-term, vibration-proof integrity).

Este grupo representa o “coração” do Tanque de expansão FAW J6P sistema. These two parts work together to control the physics of the entire cooling circuit.

1. Componente: ‘Expansion tank assy’ (1311020-76A)

Esse (Comp. 2) é o principal “Reservoir Logic.” Este é o Tanque de expansão FAW J6P em si. É um “flow-through” tanque, não é um “dead-end” overflow. Coolant and scavenged air are constantly flowing *through* it.

Made from a “heat-stabilized polymer,” isso é “Thermal Buffer Logic” allows it to safely hold expanding, 90°C+ coolant. Interno “defletores” (not visible) help “separar” the air bubbles from the liquid coolant, allowing the air to rise to the top while the air-free coolant is drawn from the bottom. O “MIN/MAX” lines on its side are a critical daily check for technicians.

2. Componente: ‘Pressure cap assy’ (1304010-50A)

Esse (Comp. 1) é o “Boiling Point Logic” and the system’s “Safety Valve.” A modern diesel engine runs *above* the normal 100°C (212° f) boiling point of water. This cap “vedações” o sistema.

Isso é “Pressurization Logic” (Por exemplo, holding 1.0 bar / 15 PSI) raises the coolant’s boiling point to ~120°C (~250°F), prevenindo “flash boiling” inside the engine head. This cap is a “dual-action” válvula:

Pressure Valve (Out): If pressure exceeds 15 PSI (Por exemplo, from a head gasket leak), a spring-loaded valve opens, venting pressure *out* to prevent the radiator or hoses from bursting.

Vacuum Valve (Em): When the engine cools, the coolant contracts, criando um “vacuum.” A second, smaller valve opens to allow air/coolant *in*, preventing the ‘Radiator outlet hose’ (Capítulo 37) de “collapsing” under suction.

Este grupo é o “arterial network” that connects the Tanque de expansão FAW J6P to the engine and radiator. Isso é “lógica” is to move both “ar” e “coolant.”

1. O “Air Scavenger” Lógica (Componentes 7, 8, 15)

Este é o “Air-Free Logic” rede. Inclui ‘Degas hose’ (1311068-61B) (Comp. 7), ‘Rear degas hose’ (1311069-61B) (Comp. 8), e ‘Degas hose’ (1311036-14B) (Comp. 15).

These small-bore hoses connect to the *highest points* of the cooling system (like the top of the ‘Radiator assy’, Capítulo 37). Deles “Scavenging Logic” is to continuously “sangrar” any trapped air bubbles *away* from the engine and *to* the Tanque de expansão FAW J6P, where they are safely separated.

2. O “Coolant Return” Lógica (Componentes 5, 12, 19)

Este é o “Plumbing Logic.” Inclui ‘Rear return water hose’ (1311033-61B) (Comp. 5), ‘Mangueira de retorno de água’ (1311033-14B) (Comp. 12), e o ‘Rear return water steel pipe assy’ (1311065-14B) (Comp. 19).

This network’s “lógica” is to take the now “de-aerated” coolant from the bottom of the Tanque de expansão FAW J6P e “retornar” it to the “frio” ou “sucção” side of the cooling system (Por exemplo, near the water pump). This ensures the water pump only ever receives a 100% sólido, air-free “cobrar” of coolant, prevenindo “cavitação” damage.

Este grupo representa o “Smallest Serviceable Units” (SSU) that are essential for the survival of the Tanque de expansão FAW J6P in a high-vibration dump truck environment.

1. O “Montagem Estrutural” Lógica (Componentes 11, 18, 20)

Este grupo forma o “Vibration Isolation Logic.” O ‘Expansion tank bracket assy’ (1311040-61C) (Comp. 11), ‘Bracket assy’ (1311070-14B) (Comp. 18), e ‘Bracket assy’ (1311075-14B) (Comp. 20) create a rigid “steel cage.” Esse “jaula” bolts to the chassis frame and securely holds the “polímero” Tanque de expansão FAW J6P (Comp. 2), isolating it from the worst of the chassis “flexionar” and engine vibration.

2. O “Selagem” Lógica (Componentes 4, 6, 13)

Este é o “Leak-Proof Logic.” O ‘Banjo-type hose clamp B model’ (CQ67640B, CQ67622B) (Comp. 4, 6) e 'Braçadeira de mangueira’ (1311077-61B) (Comp. 13) are the most critical SSUs.

O “Banjo-type” (T-Bolt) clamps provide 360-degree, alto torque “clamping force” on the main hoses. A “worm-gear” clamp would loosen under vibration. A failure of a single clamp (Por exemplo, Comp. 6) means a “catastrophic coolant loss” and engine seizure.

3. O “Anti-Chafe” Lógica (Componentes 9, 14, 17)

Este é o “Routing Protection Logic.” Este grupo inclui ‘Dual pipe clamp assy’ (1311060-61B) (Comp. 9), ‘Plastic zip tie’ (T67420376) (Comp. 14), e ‘Single pipe clamp’ (1311071A377) (Comp. 17).

O “lógica” of these parts is to “âncora” the flexible degas hoses (Comp. 7, 8, 15). O #1 killer of hoses is “chafing” (rubbing against a sharp metal bracket or hot engine part). The six ‘Plastic zip ties’ (Comp. 14) are not a “fix”; eles são “Deliberate Engineering Logic” to secure these lines, ensuring they never rub or vibrate, guaranteeing the integrity of the Tanque de expansão FAW J6P‘s plumbing.

4. O “Fixador” Lógica (Componentes 3, 10, 16)

O 'Parafuso combinado’ (CQ1460825) é o “Hardware Logic.” Esses 11 parafusos (5 + 4 + 2) are used to “seguro” the brackets (Comp. 11, 18, 20) to the truck’s chassis, completing the mounting system.

A tabela a seguir fornece o completo, detalhamento de todos 20 tipos de componentes no Tanque de expansão FAW J6P conjunto (Capítulo 38) para o FAW Jiefang CA3250P66K2L1T1E 6×4 caminhão despejando.

| Marca | Parte não. | Nome da peça | Quantidade |

|---|---|---|---|

| 1 | 1304010-50A | Pressure cap assy | 1 |

| 2 | 1311020-76A | Expansion tank assy | 1 |

| 3 | CQ1460825 | Parafuso de combinação | 5 |

| 4 | CQ67640B | Banjo-type hose clamp B model | 4 |

| 5 | 1311033-61B | Rear return water hose | 1 |

| 6 | CQ67622B | Banjo-type hose clamp B model | 8 |

| 7 | 1311068-61B | Degas hose | 1 |

| 8 | 1311069-61B | Rear degas hose | 1 |

| 9 | 1311060-61B | Dual pipe clamp assy | 2 |

| 10 | CQ1460825 | Parafuso de combinação | 4 |

| 11 | 1311040-61C | Expansion tank bracket assy | 1 |

| 12 | 1311033-14B | Mangueira de retorno de água | 1 |

| 13 | 1311077-61B | Grampo de mangueira | 2 |

| 14 | T67420376 | Gravata plástica com zíper | 6 |

| 15 | 1311036-14B | Degas hose | 2 |

| 16 | CQ1460825 | Parafuso de combinação | 2 |

| 17 | 1311071A377 | Braçadeira de tubo único | 2 |

| 18 | 1311070-14B | Bracket assy | 1 |

| 19 | 1311065-14B | Rear return water steel pipe assy | 1 |

| 20 | 1311075-14B | Bracket assy | 1 |

As especificações para o Tanque de expansão FAW J6P system are defined by its dual function of managing coolant volume and actively degassing the engine.

| Aplicação em veículos | FAW Jiefang CA3250P66K2L1T1E 6×4 Caminhão basculante |

| Grupo de sistemas | Tanque de expansão FAW J6P, Encanamento & Montagem |

| Lógica Primária | Thermal Expansion Compensation & System Pressurization |

| Lógica Secundária | Continuous Air Degassing & Scavenging |

| Core Tank Assembly | ‘Expansion tank assy’ (1311020-76A) |

| Controle de pressão | ‘Pressure cap assy’ (1304010-50A) |

| Degas Hoses (Scavengers) | 1311068-61B, 1311069-61B, 1311036-14B |

| Return Hoses/Pipes (Feed) | 1311033-61B, 1311033-14B, 1311065-14B |

| Core Mounting Hardware | ‘Expansion tank bracket assy’ (1311040-61C) |

| Anti-Chafe Hardware | ‘Plastic zip tie’ (T67420376) – Quantidade 6, ‘Dual pipe clamp’ (1311060-61B) |

Peças FAW, incluindo o conjunto do bloco de cilindros, são embalados com cuidado para garantir uma entrega segura. Cada componente é protegido por materiais de proteção para evitar danos durante o transporte. A rede logística garante envios pontuais em todo o mundo, apoiando operações de manutenção eficientes. Abaixo está uma imagem ilustrando a embalagem padrão para peças de caminhão FAW, mostrando a atenção aos detalhes no manuseio e armazenamento.

Esta abordagem de embalagem minimiza o risco de corrosão ou danos por impacto, garantindo que peças como o conjunto do bloco de cilindros FAW cheguem em perfeitas condições. Os clientes podem confiar na logística da FAW para obter qualidade e confiabilidade consistentes.