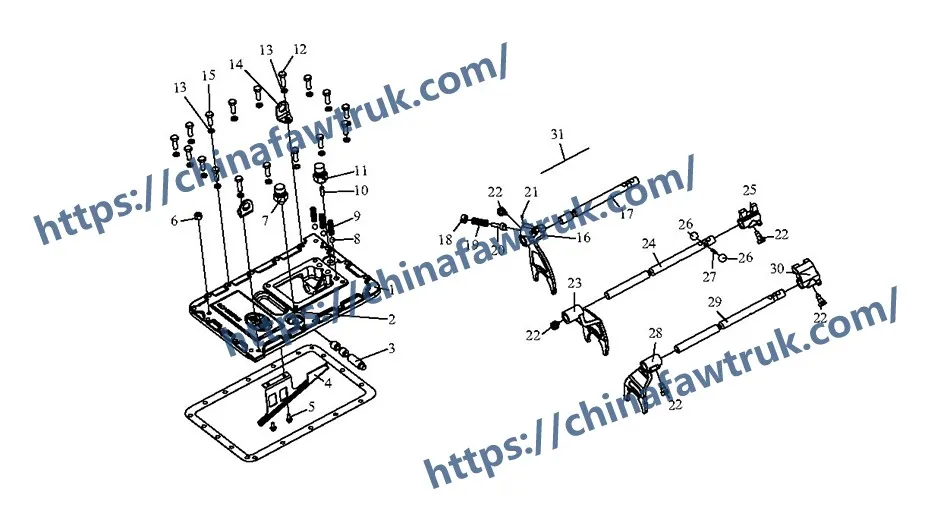

Bienvenue dans cette analyse technique complète du Couvercle supérieur FAW J6P assemblée, le “command and control” center for the CA10TA160M manual transmission. This guide is for the FAW Jiefang CA3250P66K2L1T1E 6×4 tombereau, tout déconstruire 31 composants, du principal Couvercle supérieur FAW J6P casting to every interlock pin and shift fork.

Le Couvercle supérieur FAW J6P est le “cerveau” of the manual gearbox. Its logic is to house the entire shift rail mechanism, translating the driver’s hand movements into the precise mechanical action of the shift forks. It also contains the critical interlock system that prevents mis-shifts and protects the gearbox from damage.

This group represents the foundational “châssis” of the entire shift mechanism. Tous 30 other components in this list are mounted *inside* or *onto* this single part, le Couvercle supérieur FAW J6P.

1. Composant: ‘Upper cover’ (1702026-A7G)

Ce (Comp 1) est le Couvercle supérieur FAW J6P lui-même. C'est un véhicule robuste, complex component, precision-cast from iron or aluminum. Sa logique est triple:

Le Logique d'alignement est sa fonction la plus critique. Le Couvercle supérieur FAW J6P is machined with multiple, perfectly parallel bores. These bores are the “tunnels” that support the three main “Shift fork shafts” (Comp 17, 24, 29). Any warping or damage to this cover will cause the shafts to bind, making shifting difficult or impossible.

Le Logique d'étanchéité is its second function. This component acts as the “couvercle” for the entire gearbox, sealing the top opening of the main case and keeping the high-temperature gear oil contained. This seal is created by a gasket and the numerous bolts (Comp 5, 12, 15) that provide clamping force.

Le Logique de montage is its third function. Le Couvercle supérieur FAW J6P provides the threaded holes and mounting bosses for all the system’s sensors, like the ‘Neutral indicator switch’ (Comp 7) and ‘Reverse light switch’ (Comp 11).

2. Composant: ‘Lifting lug’ (1702096-A7G)

Ce (Comp 14) is a heavy-duty steel bracket bolted to the Couvercle supérieur FAW J6P. C'est Logique de service est de fournir une forte, balanced attachment point for an engine hoist, allowing a technician to safely lift the entire, heavy transmission assembly out of the truck chassis.

3. Composant: ‘Oil guide groove’ (1702083-A7G) & 'Bouchons’ (Comp 2, 6)

The ‘Oil guide groove’ (Comp 4) is a small but clever component inside the Couvercle supérieur FAW J6P, designed to channel “splashed” oil directly onto the shift rails to keep them lubricated. The ‘Hex socket tapered plugs’ (Comp 2, 6) are used to seal any machining or service ports in the casting.

This group represents the complete mechanical assembly, housed within the Couvercle supérieur FAW J6P, that is responsible for engaging First and Reverse gears.

1. Composants: ‘Shift fork shaft – 1st/Rev’ (1702041-A7G) & 'Fourche de changement de vitesse – 1st/Rev’ (1702046-A7G)

Ce (Comp 17 & 16) is the core 1st/Reverse linkage. The ‘Shift fork shaft’ (Comp 17) is the hardened steel rod that slides fore-and-aft inside the Couvercle supérieur FAW J6P. The ‘Shift fork’ (Comp 16) is the rigid lever that is locked onto this shaft.

Le Logique d'actionnement c'est simple: the driver’s gear lever moves this shaft (Comp 17) forward or backward. The fork (Comp 16) moves with it, et son “dents” engage the ‘Sliding gear sleeve’ (on the Second Axis) to lock either the 1st gear or the Reverse gear.

2. Le “Detent” Groupe (Comp 18, 19, 20, 21)

Ce groupe comprend: ‘Plug – 1st/Rev shift fork’ (Comp 18), 'Printemps – plunger’ (Comp 19), ‘Plunger – 1st/Rev’ (Comp 20), and ‘Locking screw’ (Comp 21).

Le Logique de positionnement is the function of this sub-assembly. The ‘Shift fork shaft’ (Comp 17) has three small “V” grooves machined into it (one for 1st, one for Neutral, one for Reverse).

Le « printemps »’ (Comp 19) pushes the ‘Plunger’ (Comp 20) with high force into these grooves. C'est le “détente” that gives the shift lever its “instantané” et “click.” It holds the gear in place and prevents it from popping out under load. This entire assembly is threaded into the Couvercle supérieur FAW J6P.

This group contains the two remaining shift rails and forks, which are also precisely aligned by the Couvercle supérieur FAW J6P.

1. Le “2nd/3rd” Groupe (Comp 23, 24, 25)

Cela comprend: 'Fourche de changement de vitesse – 2nd/3rd’ (Comp 23), ‘Shift fork shaft – 2nd/3rd’ (Comp 24), and ‘Guide block – 2nd/3rd’ (Comp 25).

Le Logique d'actionnement is identical to the 1st/Rev rail. The ‘Shaft’ (Comp 24) slides within the Couvercle supérieur FAW J6P, moving the ‘Fork’ (Comp 23) to engage the 2nd/3rd synchronizer sleeve. The ‘Guide block’ (Comp 25) is a small key that locks the fork to the shaft, forcing them to move as one unit.

2. Le “4th/5th” Groupe (Comp 28, 29, 30)

Cela comprend: 'Fourche de changement de vitesse – 4th/5th’ (Comp 28), ‘Shift fork shaft – 4th/5th’ (Comp 29), and ‘Shift block – 4th/5th’ (Comp 30).

This is the final shift rail assembly. The ‘Shaft’ (Comp 29) slides in the Couvercle supérieur FAW J6P, moving the ‘Fork’ (Comp 28) and its ‘Shift block’ (Comp 30) to engage the 4th/5th synchronizer sleeve. The ‘Shift block’ est le “wear pad” that actually touches the ‘Sliding gear sleeve’.

This group contains the “sécurité” features of the Couvercle supérieur FAW J6P. Its logic is to A) provide feedback to the driver/ECU, and B) physically prevent a dangerous mis-shift.

1. Le “Interlock” Groupe (Comp 26, 27)

Ce groupe comprend: ‘Interlock steel ball’ (Comp 26, Quantité 2) and ‘Interlock pin’ (Comp 27). These components are *not* detents; they are the “verrouillage” système.

Le Logique de sécurité est leur fonction. These small pins and balls sit in special cross-drillings *between* the three shift rails (Comp 17, 24, 29) à l'intérieur du Couvercle supérieur FAW J6P. When one rail moves (Par exemple, to engage 3rd gear), it pushes these pins and balls sideways. Ce, à son tour, *physically blocks* the other two rails, making it *impossible* for them to move from their neutral position. Ce Couvercle supérieur FAW J6P interlock system is what prevents a driver from ever engaging two gears at once.

2. Le “Detent” Groupe (Comp 8, 9)

Cela comprend: ‘Self-lock steel ball’ (Comp 8, Quantité 3) and ‘Self-lock spring’ (Comp 9, Quantité 3). This is the *main* detent system (separate from the plunger in Core 2). One set is used for each of the three shift rails. The springs (Comp 9) push the balls (Comp 8) into the V-grooves on the shafts, fournissant le “instantané” et “cliquez” feel for all gears.

3. Le “Capteur” Groupe (Comp 7, 11)

Ce groupe comprend: ‘Neutral indicator switch’ (Comp 7) and ‘Reverse light switch assy’ (Comp 11).

Le Feedback Logic est leur fonction. These two sensors are threaded into the Couvercle supérieur FAW J6P. Their plungers rest against the shift rails. When the 1st/Rev rail moves to “Inverse,” it depresses the ‘Reverse light switch’ (Comp 11), turning on the truck’s reverse lights. When all rails are in their center position, the ‘Neutral indicator switch’ (Comp 7) is depressed, telling the truck’s ECU (and the driver) that it is safe to start the engine.

This final group contains all the remaining hardware that holds the Couvercle supérieur FAW J6P together and secures the internal components.

1. Le “Boulons principaux” (Comp 5, 12, 15)

Cela comprend: « Boulon à bride hexagonale’ (Comp 5, Quantité 2), ‘Hexagon bolt’ (Comp 12, Quantité 2), and ‘Hexagon bolt’ (Comp 15, Quantité 15).

Le Logique de serrage est leur fonction. These are the main bolts that fasten the Couvercle supérieur FAW J6P (Comp 1) to the main gearbox housing, compressing the gasket (non répertorié) to create the vital oil seal. The ‘Spring washer’ (Comp 13) works with these bolts to prevent them from vibrating loose.

2. Le “Internal Fasteners” (Comp 22, 31)

Cela comprend: ‘Fastening screw’ (Comp 22, Quantité 5) et « Ligne de verrouillage en fil d'acier’ (Comp 31, Quantité 5).

Le Critical Safety Logic is the function of this pair. The five ‘Fastening screws’ (Comp 22) are what lock the shift forks (Comp 16, 23, 28) to their respective shafts (Comp 17, 24, 29).

Because these screws are *inside* the Couvercle supérieur FAW J6P, if one backed out, it would cause a total shift failure. Pour éviter cela, ils sont “safety-wired.” The ‘Steel wire lock line’ (Comp 31) is threaded through holes in the heads of the screws (Comp 22) and twisted tight, making it physically *impossible* for the screws to ever vibrate loose.

Le tableau suivant fournit l'intégralité, ventilation détaillée de tous 31 types de composants dans le Couvercle supérieur FAW J6P and shift rail assembly for the FAW Jiefang CA3250P66K2L1T1E 6×4 tombereau.

| Marque | Partie no. | Nom de la pièce | Quantité |

|---|---|---|---|

| 1 | 1702026-A7G | Upper cover | 1 |

| 2 | Q61901 | Hex socket tapered plug | 1 |

| 3 | 1702076-A7G | Air valve shaft | 1 |

| 4 | 1702083-A7G | Oil guide groove | 1 |

| 5 | Q1840616S | Boulon à bride hexagonale | 2 |

| 6 | Q61903 | Hex socket tapered plug | 1 |

| 7 | 3774010-367 | Neutral indicator switch | 1 |

| 8 | Q967165 | Self-lock steel ball | 3 |

| 9 | 1702061-A7G | Self-lock spring | 3 |

| 10 | 1702086-A7G | Reverse indicator light switch | 1 |

| 11 | 3729100-71UN | Reverse light switch assy | 1 |

| 12 | CQ1501035S | Boulon hexagonal | 2 |

| 13 | Q40310 | Rondelle élastique | 17 |

| 14 | 1702096-A7G | Lifting lug | 2 |

| 15 | CQ1501030S | Boulon hexagonal | 15 |

| 16 | 1702046-A7G | Fourchette de changement de vitesse – 1st/Rev | 1 |

| 17 | 1702041-A7G | Shift fork shaft – 1st/Rev | 1 |

| 18 | 1702049-A7G | Prise – 1st/Rev shift fork | 1 |

| 19 | 1702048-A7G | Printemps – plunger | 1 |

| 20 | 1702047-A7G | Piston – 1st/Rev | 1 |

| 21 | 1702051-A7G | Locking screw | 1 |

| 22 | 1702056-A7G | Fastening screw | 5 |

| 23 | 1702037-A7G | Fourchette de changement de vitesse – 2nd/3rd | 1 |

| 24 | 1702036-A7G | Shift fork shaft – 2nd/3rd | 1 |

| 25 | 1702038-A7G | Bloc de guidage – 2nd/3rd | 1 |

| 26 | 1702063-A7G | Interlock steel ball | 2 |

| 27 | 1702064-A7G | Interlock pin | 1 |

| 28 | 1702032-A7G | Fourchette de changement de vitesse – 4th/5th | 1 |

| 29 | 1702031-A7G | Shift fork shaft – 4th/5th | 1 |

| 30 | 1702033-A7G | Shift block – 4th/5th | 1 |

| 31 | Q50512250 | Ligne de verrouillage en fil d'acier | 5 |

Les spécifications pour le Couvercle supérieur FAW J6P sont définis par sa fonction de système complet “centre de commande” for the manual, 5-speed main gearbox, housing all shift rails and interlock systems.

| Demande de véhicule | FAW Jiefang CA3250P66K2L1T1E 6×4 Tombereau |

| Groupe système | Couvercle supérieur FAW J6P & Shift Rail Assembly |

| Boîte de vitesses associée | CA10TA160M (10-Vitesse) |

| Logique primaire | Manual Shift Actuation, Scellage, and Rail Alignment |

| Composant principal | ‘Upper cover’ (1702026-A7G) |

| Shift Rail Systems | 1st/Reverse, 2nd/3rd, 4th/5th |

| Système de sécurité 1 (Detent) | ‘Self-lock steel ball’ (Q967165) & 'Printemps’ (1702061-A7G) |

| Système de sécurité 2 (Interlock) | ‘Interlock steel ball’ (1702063-A7G) & ‘Pin’ (1702064-A7G) |

| Système de sécurité 3 (Attache) | «Ligne de verrouillage en fil d'acier’ (Q50512250) for ‘Fastening screw’ (1702056-A7G) |

| Capteurs (Mounted to Cover) | ‘Neutral indicator switch’ & ‘Reverse light switch assy’ |

| Types de composants totaux | 31 |

| Système associé | Main Gearbox Internals (Synchronizers, Manches) |

Pièces FAW, y compris l'ensemble bloc-cylindres, sont emballés avec soin pour garantir une livraison en toute sécurité. Chaque composant est sécurisé dans des matériaux de protection pour éviter tout dommage pendant le transport. Le réseau logistique garantit des expéditions ponctuelles dans le monde entier, soutenir des opérations de maintenance efficaces. Vous trouverez ci-dessous une image illustrant l'emballage standard des pièces de camion FAW., mettant en valeur l’attention portée aux détails dans la manipulation et le stockage.

Cette approche d'emballage minimise le risque de corrosion ou de dommages causés par les chocs., s'assurer que les pièces comme l'ensemble bloc-cylindres FAW arrivent en parfait état. Les clients peuvent compter sur la logistique de FAW pour une qualité et une fiabilité constantes.