Welcome to the definitive guide on the FAW J6P Front Seat for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck. This is not just a passenger seat; it’s a critical safety component. This article deconstructs the 2 key parts—the main seat assembly and its high-strength mounting hardware—vital for passenger security and durability.

The FAW J6P Front Seat serves a different role than its driver-side counterpart. While the driver’s seat focuses on pneumatic, adjustable control, the passenger seat is engineered for absolute durability, structural integrity, and occupant safety in a high-vibration environment.

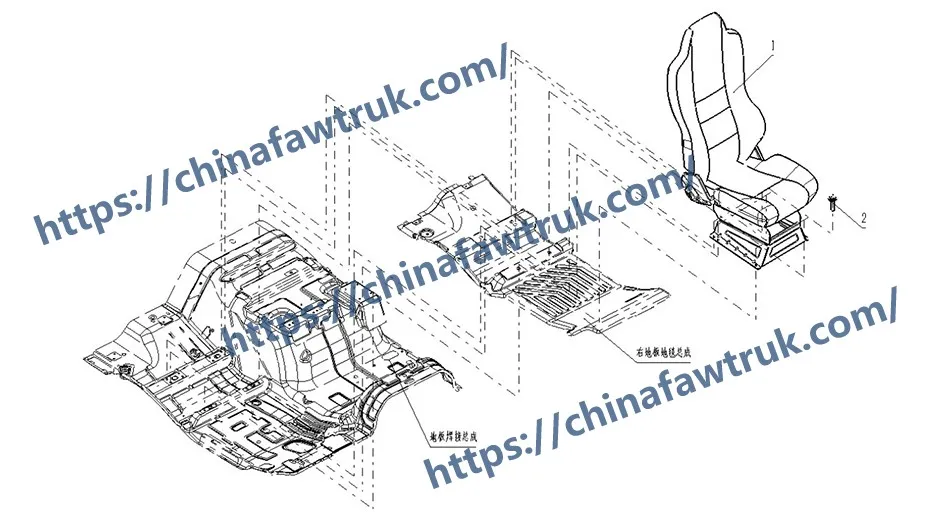

This teardown of the FAW J6P Front Seat (Part No. 6900010AB35-C00) analyzes its static, high-strength frame, its heavy-duty upholstery, and the critical mounting system that anchors it to the cab floor. For technicians, understanding this assembly is key for replacements, safety inspections, and ensuring cab integrity.

The CA3250P66K2L1T1E operates in extreme conditions, from quarries to construction sites. The FAW J6P Front Seat is designed to handle this abuse, providing a secure, stable platform for the passenger, which is essential for both comfort and safety during off-road travel. We will explore the non-negotiable components of this system.

This is the primary component of the FAW J6P Front Seat system. It is a complete, pre-assembled unit designed for passenger safety and durability, rather than the complex pneumatic adjustments of the driver’s side.

1. Component: ‘Front Seat Assy’ (6900010AB35-C00) – Qty 1

This (Mark 1) is the complete passenger seat assembly. The ‘Assy’ (总成) designation confirms it is a fully integrated, non-serviceable unit, including the frame, foam, and upholstery. It is engineered as a complete safety system.

The Static Frame Logic: Unlike the driver’s pneumatic seat, the FAW J6P Front Seat is built on a high-strength, fixed steel frame. Its primary logic is structural integrity. The frame is designed to withstand extreme forces, particularly those experienced during a collision, and to safely transfer the occupant’s load to the cab structure.

This fixed design eliminates the moving parts of a suspension seat, maximizing rigidity and strength. The steel is treated for corrosion resistance to ensure a long service life within the cab environment. This frame is the core of the seat’s passive safety.

The frame itself is constructed from high-gauge stamped steel, robotically welded for perfect consistency and strength at every seam. This is critical, as any flaw in a weld could become a failure point during an impact.

After welding, the frame for the FAW J6P Front Seat undergoes a full e-coating (electrophoretic deposition) process. This is not just paint; it is a complete immersion process that coats every surface, inside and out, with a durable, anti-corrosion layer. This prevents rust from forming in the humid, high-condensation environment of a truck cab.

The Ergonomic Logic: While static, the FAW J6P Front Seat provides essential comfort for the passenger. The frame is ergonomically shaped to provide support during long hauls on rough terrain. The foam used is a high-density, closed-cell polyurethane.

This foam is specifically engineered with a high “rebound factor.” This means it resists ‘packing down’ or taking a permanent set over time, providing firm, consistent support for years. This is unlike cheap foams that collapse and offer no support after a few months of use.

The upholstery is a heavy-duty, flame-retardant, and wear-resistant fabric. This material is specifically chosen for its high abrasion resistance, able to withstand the abuse of a construction or job-site environment, where personnel may enter the cab with tools or in dirty workwear. It is also easy to clean and maintains its integrity.

The Integrated Safety Logic: This FAW J6P Front Seat assembly is a critical component in the vehicle’s passive safety system. The seatbelt anchors (buckle) are often integrated directly into the seat frame itself. This is a crucial design choice.

By anchoring the belt to the seat, the geometry between the passenger’s hip and the anchor point remains constant, regardless of the passenger’s size. This ensures the seatbelt engages correctly across the pelvis, which is vital for preventing injury.

This design means the FAW J6P Front Seat frame is engineered to handle the immense, focused forces of the seatbelt during an emergency stop or impact. The load is then transferred from the seat frame, through the mounting bolts (Core 2), and into the reinforced cab floor.

The Service Logic: As an ‘Assy’, this part is replaced as a single unit. A technician should not attempt to repair a bent frame or re-upholster a torn seat. Doing so would compromise its safety certification and factory-engineered load paths.

Any damage to the frame or its mounting points, especially after an accident, necessitates a full replacement of the 6900010AB35-C00 assembly to guarantee passenger safety. This is a non-negotiable point of liability and safety.

A seat’s safety is entirely dependent on its connection to the vehicle. The mounting system for the FAW J6P Front Seat is identical to the driver’s side and is a non-negotiable safety-critical component.

1. Component: ‘Combination Bolt’ (CQ1460825F6) – Qty 6

This (Mark 2) is the set of six specialized, high-tensile bolts that physically secure the FAW J6P Front Seat assembly (Mark 1) to the reinforced bosses on the cab floor. They are the final link in the passenger safety chain.

The ‘Combination’ Logic: The name ‘Combination Bolt’ (组合螺栓) is specific. It means this is a pre-assembled component where a captive lock washer (specifically, a spring or “split” washer) and a flat washer are permanently attached to the bolt.

This design is essential in high-vibration applications. It makes installation foolproof, guaranteeing the lock washer is never forgotten. The spring washer exerts constant tension, preventing the bolt from backing out due to the constant, high-frequency vibrations of the truck’s chassis.

The Strength Logic: These are not standard hardware. They are high-tensile, automotive-grade steel bolts, typically Grade 10.9. This grade specifies a minimum tensile strength of 1040 MPa, meaning they can withstand enormous force before breaking.

These bolts are engineered to withstand massive shear forces (side-to-side) and tensile forces (pulling out) simultaneously. In a collision, these six bolts must manage the entire load of the passenger and the heavy FAW J6P Front Seat assembly, preventing the seat from breaking loose.

A loose FAW J6P Front Seat, felt as a ‘clunk’ or shift, is a critical safety failure. It indicates these bolts have lost torque and must be re-torqued or replaced immediately.

The Service Logic: These bolts have a specific, high-torque specification. A technician must *always* use a calibrated torque wrench for installation and tighten them in a cross-pattern to ensure the seat base mates flatly with the floor.

Critically, these bolts are often ‘Torque-to-Yield’ (TTY). This means they are designed to be stretched *once* to their elastic limit to achieve maximum clamping force. Once removed, they are permanently stretched and cannot be safely re-used.

It is mandatory to replace these bolts (CQ1460825F6) any time a FAW J6P Front Seat is replaced. Re-using old, stretched bolts is a serious safety risk, as they will not achieve the correct torque and can snap under load.

The following table provides the complete, detailed breakdown of all 2 component types specified for the FAW J6P Front Seat system on the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 6900010AB35-C00 | Front Seat Assy | 1 |

| 2 | CQ1460825F6 | Combination Bolt | 6 |

The specifications for the FAW J6P Front Seat are defined by its primary role as a structural safety component for the passenger.

| Vehicle Application | FAW Jiefang CA3250P66K2L1T1E 6×4 Dump Truck |

| System Group | FAW J6P Front Seat (Passenger Seat) |

| Primary Assembly | ‘Front Seat Assy’ (6900010AB35-C00) |

| Suspension Type | Static / Fixed (Non-Pneumatic) |

| Frame Construction | High-Strength, Robotically Welded Steel |

| Frame Coating | E-Coating (Electrophoretic) for Anti-Corrosion |

| Key Feature | Integrated Seatbelt Anchor Points |

| Upholstery | Heavy-Duty, Wear-Resistant Fabric |

| Mounting System | ‘Combination Bolt’ (CQ1460825F6) |

| Bolt Quantity | 6 |

| Bolt Type | High-Tensile (e.g., Grade 10.9), Combination |

| Total Component Types | 2 |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.