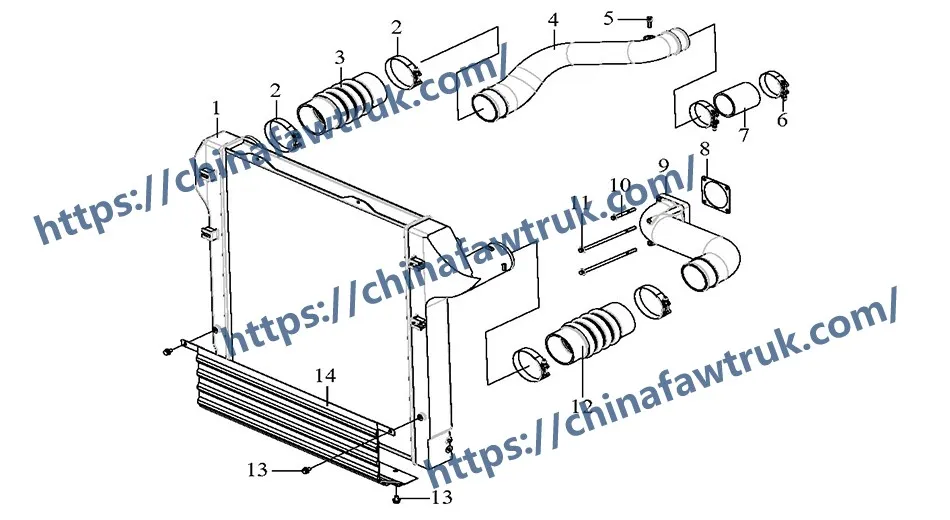

Il s'agit d'une déconstruction technique complète du FAW J6P suspendu système (Chapitre 39). This is *not* the vehicle’s main suspension (Chapitre 50), mais le “Logique d'isolation des vibrations” system for the Charge Air Cooler (CAC) sur le FAW Jiefang CA3250P66K2L1T1E 6×4 tombereau. Its sole purpose is to “suspend” the ‘Intercooler assy’ (Comp 1), protecting the “doux” aluminum core from “fatigue failure.”

Le “Differential Movement Logic” is the problem this FAW J6P suspendu system solves. Le “moteur” (which twists on its mounts) et le “châssis” (which flexes over terrain) move *independently*. Bolting the rigid ‘Intercooler’ (Comp 1) to both would “larme” it apart in days.

Le FAW J6P suspendu le système est le “Flexible Coupling Logic” que “bridges the gap.” Il utilise “corrugated” (bellows-style) tuyaux (Comp 3, 12) et “high-temp” silicone hoses (Comp 7) à “absorb” ce “differential movement.” A failure in this system—a loose clamp or a cracked hose—means a “boost leak,” a catastrophic loss of power, and potential engine damage.

This guide is essential for all chassis technicians. We will deconstruct all 14 composants, analyser le “Flexible Coupling Logic” (the corrugated hoses), le “Vulnerable Asset” (the intercooler itself), le “Boost-Proof Sealing Logic” (the heavy-duty clamps), et le “Physical Protection Logic” (the ‘Guard net assy’ que “suspends” in front of the core).

Ce groupe représente le “cœur” de la FAW J6P suspendu système. Ce sont les “flexible joints” that absorb the vibration.

1. Composant: ‘Inlet/Outlet corrugated connecting hose assy’ (1119050-50UN, 1119060-50UN)

Ces (Comp 3, 12) sont les “Logique d'isolation des vibrations” composants. They are engineered as “corrugated” (bellows-style) couplers. Leur “logique” est de “fléchir” in multiple axes.

Ce “Differential Movement Logic” est la clé. Le “moteur” (lequel “twists” under torque) et le “châssis” (lequel “fléchit” over rough terrain) sont “de-coupled.” These hoses are the “flexible bridge” that allows the engine and chassis to “move independently” sans “stressing” the rigid intercooler.

2. Composant: ‘Turbocharger outlet hose’ (1119057A263)

Ce (Comp 7) est le “High-Temp Flexible Logic.” It connects the “chaud” (150°C+) turbocharger outlet to the ‘Inlet corrugated hose’ (Comp 3).

This hose is a critical part of the FAW J6P suspendu “train.” It must be (UN) “flexible” to absorb the high-frequency “vibration” du moteur, et (B) made of “reinforced silicone” to withstand the “dual attack” of extreme heat and “oil mist” (from the turbo) that would “dissolve” a standard rubber hose.

C'est le “vulnerable asset” that the entire FAW J6P suspendu system is engineered to protect.

1. Composant: ‘Intercooler assy’ (1119010-70U)

Ce (Comp 1) est le “Charge Air Cooler” (CAC). C'est “logique” est de “cool” the hot turbo air to create “dense” (oxygen-rich) air for the engine.

C'est “Vulnerability Logic” is its *construction*. It is made of “thin-walled aluminum” tubes and “plastique” ou “aluminum” end-tanks. This material is “doux” et “brittle” against “fatigue.” Le “chassis flex” et “engine vibration” of a dump truck are “fatigue forces.”

Le FAW J6P suspendu système (the flexible hoses, Comp 3, 7, 12) “isolates” ce “vulnerable asset” (Comp 1) from these “fatigue forces.” The intercooler is “mounted” au (relatively stable) ‘Radiator assy’ (Chapitre 37), et le “tuyaux” are what “combler le fossé” au “vibrant” moteur.

UN “Logique d'échec” here is a “cracked end-tank” ou “cracked core” from vibration. Ce “boost leak” (sifflant, loss of power, fumée noire) est un “symptom” of a “échoué” FAW J6P suspendu système (Par exemple, un “bottomed-out” engine mount that transfers, rather than absorbs, vibration).

UN “suspended” system is useless if it leaks. Ce “Smallest Serviceable Unit” (SSU) group is the “Logique d'étanchéité” pour le FAW J6P suspendu assemblée.

1. Composant: ‘Heavy duty hose clamp’ (T67610006A, T6767606A)

These six (6) pinces (Comp 2, 6) sont les “Boost-Proof Logic.” Le FAW J6P suspendu tuyaux (Comp 3, 7, 12) must handle 30+ PSI of “pression de suralimentation,” qui est “trying” à “blow them off” the pipes.

Une norme “worm-gear” clamp would “bande” ou “vibrate loose.” Ces “T-Bolt” (ou “Heavy Duty”) clamps provide a “360-degré, couple élevé” “clamping force.” Ce “écluses” le “flexible” hose to the “rigide” tuyau (Comp 4, 9), créer un “joint” that is “flexible” (to absorb vibration) but “leak-proof” (to hold boost).

2. Composant: ‘Inlet pipe gasket’ (1119064-50UN)

Ce (Comp 8) est le “Final Seal Logic.” Il “scellés” the ‘Engine inlet pipe’ (Comp 9) to the engine’s intake manifold. C'est le “final link” dans le FAW J6P suspendu “chain.” It must “compress” to form a seal, but be “durable” enough to “résister à” the high-frequency “vibration” of the engine itself.

This final group “anchors” the rigid parts of the FAW J6P suspendu system and “protège” le “vulnerable asset.”

1. Composant: ‘Guard net assy’ (1310010A50AJ)

Ce (Comp 14) est le “Physical Protection Logic.” The ‘Intercooler assy’ (Comp 1) est “doux” et “delicate.” It is “suspended” at the front of the truck, “exposed” to road debris.

This ‘Guard net’ est un “sacrificiel” écran. It is “bolted” (Comp 13) in front of the ‘Intercooler’ (Comp 1). C'est “logique” est de “absorb the impact” de “rochers, bugs, et débris,” “sacrificing” itself to “protéger” the expensive, “suspended” asset behind it. UN “punctured” intercooler is an “instant failure” of the whole system.

2. Le “Rigide” Plomberie & Attaches (Comp 4, 5, 9, 10, 11, 13)

C'est le “Anchoring Logic.” Le ‘Intercooler inlet pipe’ (1119031-14B) et ‘Engine inlet pipe’ (1119062-14B) sont les “rigide” pipes that are “anchored” to the chassis/engine.

Le « Boulons à bride hexagonale’ (Comp 5, 10), ‘Connecting bolts’ (Comp 11), et ‘Combination bolts’ (Comp 13) sont les “Vibration-Proof Fastener Logic.” Ces “à bride” (autobloquant) boulons “sécurisé” these rigid pipes and the ‘Guard net’ (Comp 14) au châssis, ensuring they *never* “rattle loose.” Ce “rigid anchoring” c'est quoi “forces” le “flexible” FAW J6P suspendu tuyaux (Comp 3, 12) to do their job of “absorbing” the vibration.

Le tableau suivant fournit l'intégralité, ventilation détaillée de tous 14 types de composants dans le FAW J6P suspendu (Charge Air Cooler) assemblée (Chapitre 39) Pour le FAW Jiefang CA3250P66K2L1T1E 6×4 tombereau.

| Marque | Partie no. | Nom de la pièce | Quantité |

|---|---|---|---|

| 1 | 1119010-70U | Intercooler assy | 1 |

| 2 | T67610006A | Heavy duty hose clamp | 4 |

| 3 | 1119050-50UN | Inlet corrugated connecting hose assy | 1 |

| 4 | 1119031-14B | Tuyau d'entrée des refroidisseurs intermédiaires | 1 |

| 5 | Q1840825 | Boulon à bride hexagonale | 1 |

| 6 | T6767606A | Heavy duty hose clamp | 2 |

| 7 | 1119057A263 | Turbocharger outlet hose | 1 |

| 8 | 1119064-50UN | Joint de tuyau d'entrée | 1 |

| 9 | 1119062-14B | Tuyau d'entrée du moteur | 1 |

| 10 | Q1840870 | Boulon à bride hexagonale | 2 |

| 11 | 1119063-50UN | Boulon de connexion | 2 |

| 12 | 1119060-50UN | Outlet corrugated connecting hose assy | 1 |

| 13 | CQ1460816 | Boulon combiné | 4 |

| 14 | 1310010A50AJ | Guard net assy | 1 |

Les spécifications pour le FAW J6P suspendu system are defined by its function as the vibration isolation coupling for the Charge Air Cooler.

| Demande de véhicule | FAW Jiefang CA3250P66K2L1T1E 6×4 Tombereau |

| Groupe système | FAW J6P suspendu (CAC) Assemblée |

| Logique primaire | Isolation des vibrations (via Flexible Hoses) |

| Logique secondaire | Differential Movement Compensation & Boost Pressure Sealing |

| Core Flexible Couplers | ‘Inlet corrugated hose’ (1119050-50UN), ‘Outlet corrugated hose’ (1119060-50UN) |

| Cœur “Hot” Coupler | ‘Turbocharger outlet hose’ (1119057A263) (Silicone) |

| Protected Asset | ‘Intercooler assy’ (1119010-70U) |

| Sealing Hardware | ‘Heavy duty hose clamp’ (T67610006A, T6767606A) – 6 Total |

| Protection Hardware | ‘Guard net assy’ (1310010A50AJ) |

| Système associé | FAW J6P Turbocharger & Engine Intake |

Pièces FAW, y compris l'ensemble bloc-cylindres, sont emballés avec soin pour garantir une livraison en toute sécurité. Chaque composant est sécurisé dans des matériaux de protection pour éviter tout dommage pendant le transport. Le réseau logistique garantit des expéditions ponctuelles dans le monde entier, soutenir des opérations de maintenance efficaces. Vous trouverez ci-dessous une image illustrant l'emballage standard des pièces de camion FAW., mettant en valeur l’attention portée aux détails dans la manipulation et le stockage.

Cette approche d'emballage minimise le risque de corrosion ou de dommages causés par les chocs., s'assurer que les pièces comme l'ensemble bloc-cylindres FAW arrivent en parfait état. Les clients peuvent compter sur la logistique de FAW pour une qualité et une fiabilité constantes.