Esta é uma desconstrução técnica completa do FAW J6P suspenso sistema (Capítulo 39). This is *not* the vehicle’s main suspension (Capítulo 50), mas o “Lógica de isolamento de vibração” system for the Charge Air Cooler (CAC) no FAW Jiefang CA3250P66K2L1T1E 6×4 caminhão despejando. Its sole purpose is to “suspend” the ‘Intercooler assy’ (Comp. 1), protegendo o “macio” aluminum core from “fatigue failure.”

O “Differential Movement Logic” is the problem this FAW J6P suspenso system solves. O “motor” (which twists on its mounts) e o “chassis” (which flexes over terrain) move *independently*. Bolting the rigid ‘Intercooler’ (Comp. 1) to both would “tear” it apart in days.

O FAW J6P suspenso sistema é o “Flexible Coupling Logic” que “bridges the gap.” Ele usa “ondulado” (bellows-style) mangueiras (Comp. 3, 12) e “high-temp” silicone hoses (Comp. 7) para “absorb” esse “differential movement.” A failure in this system—a loose clamp or a cracked hose—means a “aumentar o vazamento,” a catastrophic loss of power, and potential engine damage.

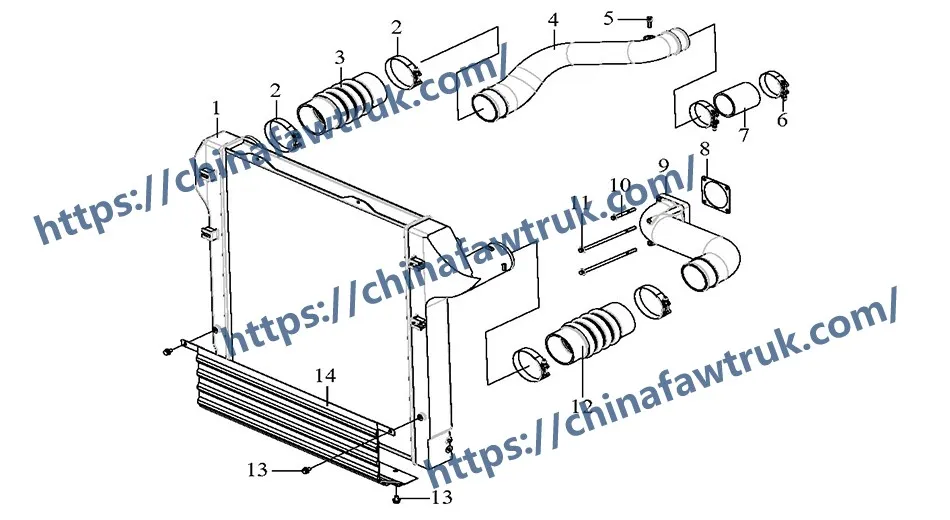

This guide is essential for all chassis technicians. We will deconstruct all 14 componentes, analisando o “Flexible Coupling Logic” (the corrugated hoses), o “Vulnerable Asset” (the intercooler itself), o “Boost-Proof Sealing Logic” (the heavy-duty clamps), e o “Physical Protection Logic” (the ‘Guard net assy’ que “suspends” in front of the core).

Este grupo representa o “coração” do FAW J6P suspenso sistema. Estes são os “flexible joints” that absorb the vibration.

1. Componente: ‘Inlet/Outlet corrugated connecting hose assy’ (1119050-50A, 1119060-50A)

Esses (Comp. 3, 12) são os “Lógica de isolamento de vibração” componentes. They are engineered as “ondulado” (bellows-style) couplers. Deles “lógica” é para “flexionar” in multiple axes.

Esse “Differential Movement Logic” é a chave. O “motor” (qual “reviravoltas” under torque) e o “chassis” (qual “flexiona” over rough terrain) são “de-coupled.” These hoses are the “flexible bridge” that allows the engine and chassis to “move independently” sem “stressing” the rigid intercooler.

2. Componente: ‘Turbocharger outlet hose’ (1119057A263)

Esse (Comp. 7) é o “High-Temp Flexible Logic.” It connects the “quente” (150°C+) turbocharger outlet to the ‘Inlet corrugated hose’ (Comp. 3).

This hose is a critical part of the FAW J6P suspenso “train.” It must be (A) “flexível” to absorb the high-frequency “vibração” do motor, e (B) made of “reinforced silicone” to withstand the “dual attack” of extreme heat and “oil mist” (from the turbo) that would “dissolve” a standard rubber hose.

Este é o “vulnerable asset” that the entire FAW J6P suspenso system is engineered to protect.

1. Componente: ‘Intercooler assy’ (1119010-70U)

Esse (Comp. 1) é o “Refrigerador de ar de carga” (CAC). Isso é “lógica” é para “legal” the hot turbo air to create “denso” (oxygen-rich) air for the engine.

Isso é “Vulnerability Logic” is its *construction*. It is made of “thin-walled aluminum” tubes and “plástico” ou “aluminum” tanques finais. This material is “macio” e “frágil” against “fatigue.” O “chassis flex” e “engine vibration” of a dump truck are “fatigue forces.”

O FAW J6P suspenso sistema (the flexible hoses, Comp. 3, 7, 12) “isolates” esse “vulnerable asset” (Comp. 1) from these “fatigue forces.” The intercooler is “mounted” para o (relatively stable) ‘Radiator assy’ (Capítulo 37), e o “mangueiras” são o que “preencher a lacuna” para o “vibrando” motor.

A “Lógica de falha” here is a “cracked end-tank” ou “cracked core” from vibration. Esse “aumentar o vazamento” (sibilando, loss of power, fumaça preta) é a “symptom” de um “failed” FAW J6P suspenso sistema (Por exemplo, a “bottomed-out” engine mount that transfers, rather than absorbs, vibração).

A “suspended” system is useless if it leaks. Esse “Smallest Serviceable Unit” (SSU) group is the “Lógica de Selagem” para o FAW J6P suspenso conjunto.

1. Componente: ‘Heavy duty hose clamp’ (T67610006A, T6767606A)

These six (6) braçadeiras (Comp. 2, 6) são os “Boost-Proof Logic.” O FAW J6P suspenso mangueiras (Comp. 3, 7, 12) must handle 30+ PSI of “aumentar a pressão,” que é “trying” para “blow them off” the pipes.

A standard “worm-gear” clamp would “tira” ou “vibrate loose.” Esses “T-Bolt” (ou “Heavy Duty”) clamps provide a “360-degree, alto torque” “clamping force.” Esse “fechaduras” o “flexível” hose to the “rígido” cano (Comp. 4, 9), criando um “selo” aquilo é “flexível” (to absorb vibration) but “à prova de vazamentos” (to hold boost).

2. Componente: ‘Inlet pipe gasket’ (1119064-50A)

Esse (Comp. 8) é o “Final Seal Logic.” Isto “vedações” the ‘Engine inlet pipe’ (Comp. 9) to the engine’s intake manifold. É o “final link” no FAW J6P suspenso “chain.” It must “compressa” to form a seal, but be “durável” enough to “suportar” the high-frequency “vibração” of the engine itself.

This final group “anchors” the rigid parts of the FAW J6P suspenso system and “protects” o “vulnerable asset.”

1. Componente: ‘Guard net assy’ (1310010A50AJ)

Esse (Comp. 14) é o “Physical Protection Logic.” The ‘Intercooler assy’ (Comp. 1) é “macio” e “delicate.” Isso é “suspended” at the front of the truck, “exposed” to road debris.

This ‘Guard net’ é a “sacrificial” tela. Isso é “bolted” (Comp. 13) in front of the ‘Intercooler’ (Comp. 1). Isso é “lógica” é para “absorb the impact” de “pedras, bugs, e detritos,” “sacrificing” itself to “protect” the expensive, “suspended” asset behind it. A “punctured” intercooler is an “instant failure” of the whole system.

2. O “Rigid” Encanamento & Fixadores (Comp. 4, 5, 9, 10, 11, 13)

Este é o “Anchoring Logic.” O ‘Intercooler inlet pipe’ (1119031-14B) e ‘Engine inlet pipe’ (1119062-14B) são os “rígido” pipes that are “anchored” to the chassis/engine.

O ‘Hexagon flange bolts’ (Comp. 5, 10), ‘Connecting bolts’ (Comp. 11), e 'Parafusos de combinação’ (Comp. 13) são os “Vibration-Proof Fastener Logic.” Esses “flangeado” (self-locking) parafusos “seguro” these rigid pipes and the ‘Guard net’ (Comp. 14) para o chassi, ensuring they *never* “rattle loose.” Esse “rigid anchoring” is what “forças” o “flexível” FAW J6P suspenso mangueiras (Comp. 3, 12) to do their job of “absorbing” the vibration.

A tabela a seguir fornece o completo, detalhamento de todos 14 tipos de componentes no FAW J6P suspenso (Refrigerador de ar de carga) conjunto (Capítulo 39) para o FAW Jiefang CA3250P66K2L1T1E 6×4 caminhão despejando.

| Marca | Parte não. | Nome da peça | Quantidade |

|---|---|---|---|

| 1 | 1119010-70U | Intercooler assy | 1 |

| 2 | T67610006A | Heavy duty hose clamp | 4 |

| 3 | 1119050-50A | Inlet corrugated connecting hose assy | 1 |

| 4 | 1119031-14B | Intercooler inlet pipe | 1 |

| 5 | Q1840825 | Parafuso de flange hexagonal | 1 |

| 6 | T6767606A | Heavy duty hose clamp | 2 |

| 7 | 1119057A263 | Turbocharger outlet hose | 1 |

| 8 | 1119064-50A | Inlet pipe gasket | 1 |

| 9 | 1119062-14B | Engine inlet pipe | 1 |

| 10 | Q1840870 | Parafuso de flange hexagonal | 2 |

| 11 | 1119063-50A | Parafuso de conexão | 2 |

| 12 | 1119060-50A | Outlet corrugated connecting hose assy | 1 |

| 13 | CQ1460816 | Parafuso de combinação | 4 |

| 14 | 1310010A50AJ | Guard net assy | 1 |

As especificações para o FAW J6P suspenso system are defined by its function as the vibration isolation coupling for the Charge Air Cooler.

| Aplicação em veículos | FAW Jiefang CA3250P66K2L1T1E 6×4 Caminhão basculante |

| Grupo de sistemas | FAW J6P suspenso (CAC) Conjunto |

| Lógica Primária | Isolamento de vibração (via Flexible Hoses) |

| Lógica Secundária | Differential Movement Compensation & Boost Pressure Sealing |

| Core Flexible Couplers | ‘Inlet corrugated hose’ (1119050-50A), ‘Outlet corrugated hose’ (1119060-50A) |

| Essencial “Quente” Coupler | ‘Turbocharger outlet hose’ (1119057A263) (Silicone) |

| Protected Asset | ‘Intercooler assy’ (1119010-70U) |

| Sealing Hardware | ‘Heavy duty hose clamp’ (T67610006A, T6767606A) – 6 Total |

| Protection Hardware | ‘Guard net assy’ (1310010A50AJ) |

| Sistema Associado | FAW J6P Turbocharger & Engine Intake |

Peças FAW, incluindo o conjunto do bloco de cilindros, são embalados com cuidado para garantir uma entrega segura. Cada componente é protegido por materiais de proteção para evitar danos durante o transporte. A rede logística garante envios pontuais em todo o mundo, apoiando operações de manutenção eficientes. Abaixo está uma imagem ilustrando a embalagem padrão para peças de caminhão FAW, mostrando a atenção aos detalhes no manuseio e armazenamento.

Esta abordagem de embalagem minimiza o risco de corrosão ou danos por impacto, garantindo que peças como o conjunto do bloco de cilindros FAW cheguem em perfeitas condições. Os clientes podem confiar na logística da FAW para obter qualidade e confiabilidade consistentes.