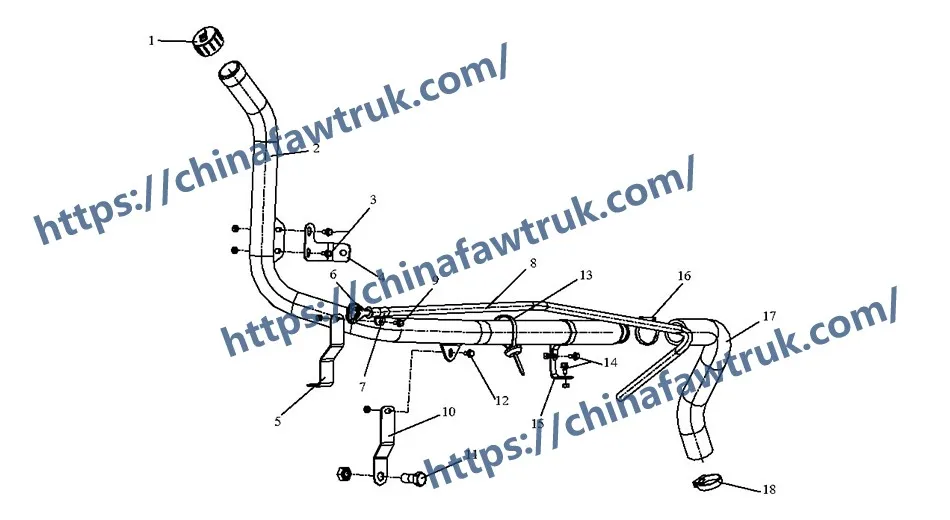

Bienvenue dans cette déconstruction experte du Bouchon de remplissage d'huile FAW J6P and Dipstick system (Chapitre 16). C'est le complet “Oil Service Port” assembly for the engine on the FAW Jiefang CA3250P66K2L1T1E 6×4 tombereau.

This 18-component group is not just a cap; c'est un complexe “Assemblage logique” that also includes the ‘Oil dipstick assy’ (Comp 6).

Le “logique” of this system is twofold: D'abord, le Bouchon de remplissage d'huile FAW J6P (Comp 1) provides a large, sécurisé, and contaminant-free port for adding oil. Deuxième, the ‘Oil dipstick’ (Comp 6) provides the means for accurate level measurement.

Le “Logique de durabilité” is the most critical feature of this entire assembly. Dans un camion-benne lourd, the engine vibrates violently. A simple, unsupported filler neck or dipstick tube would fracture from metal fatigue in weeks. Ce Bouchon de remplissage d'huile FAW J6P and dipstick system is a complex, multi-bracket assembly designed to *flex* and *move*. It uses a ‘Front support’ (Comp 4), ‘Rear support’ (Comp 10), and a ‘Soft hose’ (Comp 17) to create a system that is both rigid *and* isolated from the engine’s worst vibrations. This protects the Bouchon de remplissage d'huile FAW J6P assembly from premature failure.

This technical guide is an essential resource for fleet technicians, engine specialists, et gestionnaires de pièces. We will deconstruct the entire 18-component-type group. Nous analyserons le “Oil Filling Logic” (le Bouchon de remplissage d'huile FAW J6P, tube, and hose), le “Measurement Logic” (the dipstick and its guide tube), la critique “Logique de soutien structurel” (the multiple brackets that prevent fatigue), et le “Attache & Sécuriser la logique” qui contient la totalité Bouchon de remplissage d'huile FAW J6P assembly together.

Ce groupe “logique” is to provide a large, sécurisé, and flexible port for adding new oil to the engine. C'est la fonction première du Bouchon de remplissage d'huile FAW J6P assemblée.

1. Composant: ‘Oil filler cap assy’ (1009085-50UN)

Ce (Comp 1) est le “Primary Sealing Logic.” It is a complete assembly that includes the ‘Oil filler cap’ (1009086-50UN) et son 'Joint’ (1009087-50UN). C'est “logique” c'est être un “positive-lock” joint. It must be easy to open but must also provide a 100% airtight seal when closed. This is essential for the engine’s “Ventilation positive du carter” (PCV) système, which relies on a sealed crankcase to work correctly. A leaking Bouchon de remplissage d'huile FAW J6P est un “unmetered” air leak that can cause poor performance and oil leaks elsewhere.

2. Composants: ‘Oil filler tube’ (1009089-50UN) & ‘Oil filler soft hose’ (1009082-50UN)

C'est le “Flex Logic” and the core of the filler system’s durability. The ‘Oil filler tube’ (Comp 2) is the rigid, métal “cou” que le Bouchon de remplissage d'huile FAW J6P (Comp 1) attaches to. This tube, cependant, does not connect directly to the engine. It connects to the ‘Oil filler soft hose’ (Comp 17). Ce “logique” is intentional: the rigid tube is secured to the stable ‘Front support’ (Comp 4), Pendant que le “soft hose” flexes and moves with the vibrating engine. This isolates the rigid components from vibration, prévenir les fissures.

3. Composants: 'Serrer – B type’ (CQ67645B)

La liste en appelle à deux (2) of these clamps (Comp 16 & 18). Leur “logique” is to provide a 360-degree, high-pressure seal at both ends of the ‘Soft hose’ (Comp 17), ensuring no oil can leak from these joints. Il s'agit d'un élément essentiel du Bouchon de remplissage d'huile FAW J6P‘s plumbing.

Ce groupe “logique” is to provide an accurate oil level check, acting as the “service partner” au Bouchon de remplissage d'huile FAW J6P.

1. Composant: ‘Oil dipstick assy’ (1009095-50UN)

Ce (Comp 6) is the core ‘FAW J6P Oil Dipstick’. C'est “Measurement Logic” is its precise calibration, avec “MIN” et “MAX” marks that correspond to the exact oil level in the ‘Oil pan assy’. C'est “Logique d'étanchéité” is its handle, which features one or more O-rings. C'est critique: it doesn’t just rest in the tube; il “bouchons” il, preventing crankcase pressure from escaping and stopping dirt and water from entering the engine.

2. Composant: ‘Oil dipstick tube assy’ (1009090-50UN)

Ce (Comp 8) est le “Guide Logic.” This rigid metal tube provides a clean, safe path for the ‘Oil dipstick’ to travel from the top of the engine all the way down into the oil pan. C'est “logique” is to bypass all moving parts like the crankshaft counterweights. It must be perfectly sealed at the engine block to prevent a massive oil leak. This tube is a key part of the same service assembly as the Bouchon de remplissage d'huile FAW J6P.

C'est le “Anti-Fatigue Logic.” A long, unsupported tube (like the dipstick or filler tube) will be destroyed by engine vibration. Ce Bouchon de remplissage d'huile FAW J6P and dipstick assembly uses a “tripod” of brackets to create a robust, stable structure.

1. Composants: « Support avant’ (1009083-50UN) & ‘Rear support’ (1009084-50UN)

These two brackets (Comp 4 & 10) form the primary support for the rigid ‘Oil filler tube’ (Comp 2). The ‘Front support’ holds the “cou” of the tube (where the Bouchon de remplissage d'huile FAW J6P sits), while the ‘Rear support’ anchors the bottom. Ce “two-point” mounting logic holds the filler tube rigid and stable, so all the vibration is absorbed by the ‘Soft hose’ (Comp 17).

2. Composant: ‘Oil dipstick tube main support’ (1009081-50UN)

Ce (Comp 5) is the central “moyeu” of the support system. C'est “logique” is to act as the primary mounting point for the ‘Oil dipstick tube assy’ (Comp 8). It is a heavy-duty bracket designed to bolt securely to the engine block, providing a stable anchor point that also supports the ‘Oil dipstick clip’ (Comp 7). This ensures the entire Bouchon de remplissage d'huile FAW J6P and dipstick system is securely mounted.

Ce dernier groupe “logique” est de fournir une sécurité, résistant aux vibrations, and complete installation for the Bouchon de remplissage d'huile FAW J6P and dipstick systems.

1. Le “Serrage” Logique (Boulons, Noix, Rondelles)

The assembly uses multiple ‘Hexagon head bolts’ (Comp 3, 9, 11, 12, 14) with their associated ‘Washers’ and ‘Hexagon nuts’. Le “logique” of using a full bolt/nut/washer system (contre. a simple flange bolt) est de fournir un “through-bolt” clamp on the brackets, which is extremely resistant to vibration. This ensures all supports for the Bouchon de remplissage d'huile FAW J6P system remain secure.

2. Le “Sécurisation” Logique (Clips & Sangles)

C'est le “Secondary NVH Logic” for the flexible components.

Le tableau suivant fournit l'intégralité, ventilation détaillée de tous 18 types de composants dans le Bouchon de remplissage d'huile FAW J6P and Oil Dipstick assembly for the FAW Jiefang CA3250P66K2L1T1E 6×4 tombereau.

| Marque | Partie no. | Nom de la pièce | Quantité |

|---|---|---|---|

| 1 | 1009085-50UN 1009086-50UN 1009087-50UN | Oil filler cap assy Bouchage de remplissage d'huile Gasket-oil filler cap | 1 1 1 |

| 2 | 1009089-50UN | Oil filler tube | 1 |

| 3 | CQ1500620 Q40106 CQ34006 | Boulon à tête hexagonale Machine à laver Écrou hexagonal | 2 2 2 |

| 4 | 1009083-50UN | Front support-oil filler tube | 1 |

| 5 | 1009081-50UN | Oil dipstick tube main support | 1 |

| 6 | 1009095-50UN | Oil dipstick assy | 1 |

| 7 | 1009094-50UN | Oil dipstick clip | 1 |

| 8 | 1009090-50UN | Oil dipstick tube assy | 1 |

| 9 | CQ1500620 Q40106 CQ34006 | Boulon à tête hexagonale Machine à laver Écrou hexagonal | 1 1 1 |

| 10 | 1009084-50UN | Rear support-oil filler tube | 1 |

| 11 | CQ1501430 Q40114 CQ34014 | Boulon à tête hexagonale Machine à laver Écrou hexagonal | 1 1 1 |

| 12 | CQ1500620 Q40106 CQ34006 | Boulon à tête hexagonale Machine à laver Écrou hexagonal | 1 1 1 |

| 13 | 3724015-240 | Plastic strap assy | 3 |

| 14 | CQ1500620 Q40106 CQ34006 | Boulon à tête hexagonale Machine à laver Écrou hexagonal | 2 2 2 |

| 15 | 1009079-50UN | Oil filler tube clip | 1 |

| 16 | CQ67645B | Serrer – B type | 1 |

| 17 | 1009082-50UN | Oil filler soft hose | 1 |

| 18 | CQ67645B | Serrer – B type | 1 |

Les spécifications pour le Bouchon de remplissage d'huile FAW J6P and Dipstick assembly are defined by its function as the primary service interface for the engine’s lubrication system.

| Demande de véhicule | FAW Jiefang CA3250P66K2L1T1E 6×4 Tombereau |

| Groupe système | Bouchon de remplissage d'huile FAW J6P & Assemblage de la jauge |

| Logique primaire | Contaminant-Free Oil Filling, Accurate Oil Level Measurement |

| Logique secondaire | Anti-vibrations / Anti-Fatigue (Supports & Flex Hose) |

| Filler Seal Component | ‘Oil filler cap assy’ (1009085-50UN) |

| Filler Tube (Rigide) | ‘Oil filler tube’ (1009089-50UN) |

| Filler Tube (Flexible) | ‘Oil filler soft hose’ (1009082-50UN) |

| Measurement Component | ‘Oil dipstick assy’ (1009095-50UN) |

| Measurement Guide | ‘Oil dipstick tube assy’ (1009090-50UN) |

| Système d'assistance | ‘Front/Rear/Main supports’ (1009083-50UN, 1009084-50UN, 1009081-50UN) |

| Système de sécurisation | ‘Oil dipstick clip’ (1009094-50UN), ‘Plastic strap assy’ (3724015-240) |

| Système associé | Complet Bouchon de remplissage d'huile FAW J6P and Lubrication Service System |

Pièces FAW, y compris l'ensemble bloc-cylindres, sont emballés avec soin pour garantir une livraison en toute sécurité. Chaque composant est sécurisé dans des matériaux de protection pour éviter tout dommage pendant le transport. Le réseau logistique garantit des expéditions ponctuelles dans le monde entier, soutenir des opérations de maintenance efficaces. Vous trouverez ci-dessous une image illustrant l'emballage standard des pièces de camion FAW., mettant en valeur l’attention portée aux détails dans la manipulation et le stockage.

Cette approche d'emballage minimise le risque de corrosion ou de dommages causés par les chocs., s'assurer que les pièces comme l'ensemble bloc-cylindres FAW arrivent en parfait état. Les clients peuvent compter sur la logistique de FAW pour une qualité et une fiabilité constantes.