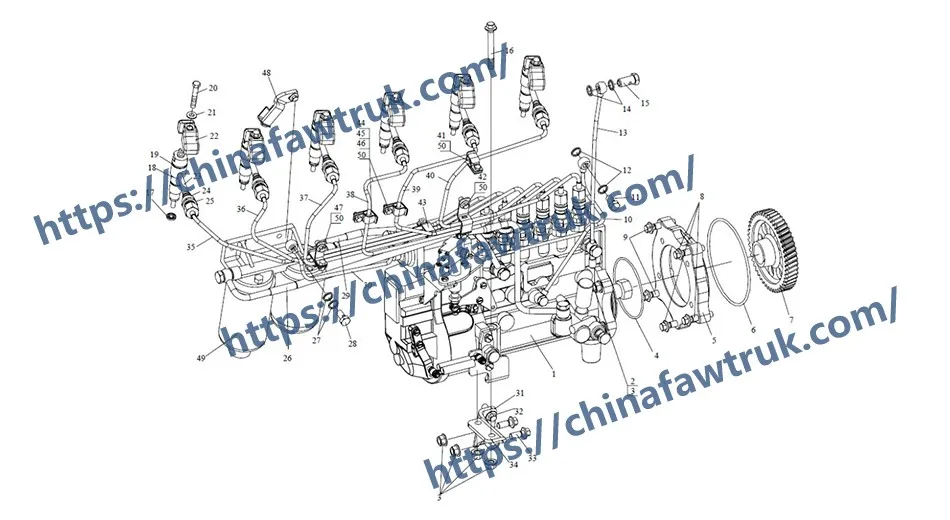

Bienvenue dans cette déconstruction experte du Système d'alimentation en carburant FAW J6P (Chapitre 23). C'est le complet “Rail commun haute pression” (Hpcr) assemblage pour le FAW Jiefang CA3250P66K2L1T1E 6×4 tombereau.

This is not a simple fuel line; c'est un complexe “Assemblage logique” de 50 types de composants, engineered for one purpose: to create and control immense pressure.

Le “logique” de ceci Système d'alimentation en carburant FAW J6P is to draw fuel, filter it, pressurize it to over 25,000 psi, and inject it as a microscopic, atomized mist directly into the cylinders at the precise microsecond it is needed.

Le “Common Rail Logic” is what defines this Système d'alimentation en carburant FAW J6P. Unlike old systems, the ‘Fuel injection pump’ (Comp 1) does not *time* the injection; it only “generates pressure.” This immense pressure is stored in the “common rail” (the high-pressure pipes, Comp 35-42). Ce “logique” allows the ‘Injectors’ (Comp 18) to be electronically controlled, independent of the pump. Ce “Multi-Shot Injection Logic” (firing multiple, tiny injections per power stroke) is what gives the engine its quiet operation, its low-end torque, its fuel efficiency, and its low emissions.

This expert guide is an essential resource for engine technicians, fuel system specialists, et gestionnaires de pièces. We will deconstruct the entire 50-component group into its four primary “logique” systèmes: le “Basse pression & Filtration Logic” (the priming pump and filter), le “High-Pressure Generation Logic” (the main injection pump), le “High-Pressure Distribution Logic” (the common rail pipes), et la critique “Injection & Logique de retour” (the injectors and return lines). Ceci est le guide complet du Système d'alimentation en carburant FAW J6P.

Ce groupe “logique” is to pull fuel from the tank, “prime” le système, and provide “Absolute Filtration” before the fuel ever reaches the expensive high-pressure pump.

1. Composant: ‘Rotary-style hand-priming pump assy’ (1117010-29D)

Ce (Comp 49) est le “Serviceability Logic.” Le Système d'alimentation en carburant FAW J6P est “self-bleeding” during normal operation, but after a filter change, the lines are full of air. Ce “hand-priming” pump’s “logique” is to allow a technician to manually *pull* fuel from the tank, *push* it through the ‘Fuel filter’ (Comp 28), and *bleed* all the air out of the system. Starting the engine with air in the lines can damage the high-pressure pump.

2. Composant: ‘Fuel filter assy’ (1012010-36D)

Ce (Comp 28) est le “System Protection Logic.” C'est le “gatekeeper” pour l'ensemble Système d'alimentation en carburant FAW J6P. Rail commun haute pression (Hpcr) components have tolerances measured in *microns*. A single grain of sand or a drop of water will *instantly* destroy the ‘Fuel injection pump’ (Comp 1) or the ‘Injectors’ (Comp 18). Ce “Absolute Filtration Logic” means this filter must remove 99.9% of all water (via an integrated separator) and all particulate matter down to 2-5 microns. A cheap, low-quality filter is the number one cause of Système d'alimentation en carburant FAW J6P échec.

Ce groupe représente le “muscle” de la Système d'alimentation en carburant FAW J6P. Its sole function is to generate over 25,000 PSI of fuel pressure.

1. Composant: ‘Fuel injection pump assy’ (1111010C31E)

Ce (Comp 1) est le “Pressure Logic.” This is a high-precision, “positive displacement” pompe (likely a 3-piston radial pump). Il faut le “low-pressure” (60-90 psi) fuel from the filter (Comp 28) and compresses it to an immense 25,000+ psi. C'est “self-lubrication” logic is that it uses the diesel fuel itself as its *only* lubricant. This is another reason why the ‘Fuel filter’ (Comp 28) is so critical.

2. Composant: ‘Fuel injector drive gear’ (1111216-59D)

Ce (Comp 7) est le “Drive Logic.” This high-pressure pump is not electric. It is “gear-driven” directly from the engine’s internal “Train à engrenages de synchronisation.” Ce “Gear-Drive Logic” est un “durée de vie du moteur” solution, as it is 100% reliable and perfectly timed with the engine’s rotation.

3. Composants: ‘Support-fuel injection pump’ (1111101-31E) & 'Support’ (1111102-29D)

These brackets (Comp 31 & 34) sont les “Alignment Logic.” The ‘Drive gear’ (Comp 7) must mesh *perfectly* with the engine’s timing gear. These heavy-duty, cast brackets bolt to the engine block and provide a rigid, precision-machined mounting flange that guarantees this perfect alignment.

4. Composants: ‘Lube oil pipe assy’ (1104060-29D) & ‘Hollow bolt’ (1104066-367)

Ce (Comp 10 & 11) est le “Pump Lubrication Logic.” While the *pumping* side of the HPCR pump is fuel-lubricated, c'est “conduire” côté (with its own bearings and camshaft) is lubricated by *engine oil*. This pipe’s “logique” est de “robinet” clean oil from the engine block and feed it directly to the pump’s bearings, ensuring its long-term durability. This is a critical link for the Système d'alimentation en carburant FAW J6P.

This group forms the “Rampe commune” lui-même. C'est “logique” est d'agir comme un “pressure reservoir” ou “accumulator,” storing the 25,000+ PSI from the pump and distributing it to all six injectors.

1. Composants: ‘High-pressure fuel pipe assy’ (Cym 1-6) (1129010… à …1129060-31E)

Ces (Comp 35-40) are the six individual “injector lines.” These are the most critical pipes in the Système d'alimentation en carburant FAW J6P. Leur “logique” est “Identical Length.” They are *all* precisely bent to be the exact same length. This is crucial. If one pipe were shorter, le “pressure waves” from the injector firing would be different, causing Cyl 1 to get a different pressure “impulsion” than Cyl 6. By making them identical, le “pressure-wave logic” is balanced, ensuring every cylinder gets the *exact* same fuel, for a smooth, balanced engine.

2. Composants: ‘High-pressure fuel pipe clip/base/gasket’ (1129100-29D, etc.)

This group (Comp 41-48) est le “Nvh & Safety Logic.” The six high-pressure pipes (Comp 35-40) “throb” violently with every injection event. If allowed to touch each other or the engine, they would “irriter,” vibrer, and develop a “fatigue crack.” A high-pressure fuel leak at 25,000 PSI is not a “drip”—it is an *atomized*, highly-flammable mist that will instantly cause a massive engine fire. Le “logique” of these clips and brackets is to hold every pipe perfectly rigid and isolated, preventing this critical failure in the Système d'alimentation en carburant FAW J6P.

Ce dernier groupe “logique” is to perform the “final event”: injecting the high-pressure fuel into the cylinder.

1. Composant: ‘Injector’ (1112010-31E)

Ce (Comp 18) est le “Atomization Logic.” It is a high-speed, electronically-controlled (solenoid or piezo) needle valve. When the ECU commands, it opens for a few *microseconds*. Le 25,000+ PSI pressure forces the fuel through microscopic holes in its nozzle, “atomizing” it into a vapor-like mist that ignites instantly for maximum power.

2. Le “Scellage” Logique: ‘Injector gasket’ (1112306-29D) & 'Joint torique’ (1112014-29D)

The injector (Comp 18) must be sealed from two things. Le « Joint »’ (Comp 17) is a copper “rondelle d'écrasement” en bas. C'est “logique” is to seal the 2000+ PSI of *combustion pressure* out. The ‘O-ring’ (Comp 19) is a rubber seal at the top. C'est “logique” is to seal the low-pressure “fuel return” *in*, preventing fuel from leaking onto the hot engine.

3. Le “Serrage” Logique: ‘Injector presser plate’ (1112013-29D) & 'Boulon’ (1112011-29D)

Ce “Logique de serrage” is what holds the injector in its bore. The ‘Bolt’ (Comp 21) pulls up on the ‘Presser plate’ (Comp 20), which pivots and creates a high “downward” force on the injector. This force is what “écrase” the ‘Gasket’ (Comp 17) to create the combustion-proof seal.

4. Le “Return” Logique: ‘Fuel injector return pipe assy’ (1104050-29D)

Ce (Comp 13) est le “Bypass Cooling Logic.” The HPCR pump and injectors “by-pass” a large amount of fuel to cool and lubricate their own moving parts. This ‘Return pipe’ “logique” is to collect all this “used” fuel from the injectors and the pump and route it safely back to the fuel tank. This is a vital part of the Système d'alimentation en carburant FAW J6P‘s thermal management.

Le tableau suivant fournit l'intégralité, ventilation détaillée de tous 50 types de composants dans le Système d'alimentation en carburant FAW J6P Pour le FAW Jiefang CA3250P66K2L1T1E 6×4 tombereau.

| Marque | Partie no. | Nom de la pièce | Quantité |

|---|---|---|---|

| 1 | 1111010C31E (1111010-675-0000TH) | Ensemble de pompe d'injection de carburant | 1 |

| 2 | CQ1201030 | Double-ended stud | 4 |

| 3 | CQ39610 | Noix de bride hexagone | 4 |

| 4 | CQ73421000C | O-ring for pneumatic | 1 |

| 5 | 1111228-30E (1111228-633-0000) | Check valve – pompe à carburant | 1 |

| 6 | CQ73421500C | O-ring for pneumatic | 1 |

| 7 | 1111216-59D (1111216-630-0000) | Fuel injector drive gear | 1 |

| 8 | Q1841045 | Boulon à bride hexagonale | 3 |

| 9 | Q1841030 | Boulon à bride hexagonale | 2 |

| 10 | 1104060-29D | Lube oil pipe assy | 1 |

| 11 | 1104066-367 | Boulon creux – lube oil pipe assy | 1 |

| 12 | CQ72310T5 | Joint | 1 |

| 13 | 1104050-29D | Fuel injector return pipe assy | 1 |

| 14 | CQ72314T5 | Joint | 2 |

| 15 | 1104073-D6 | Boulon creux – oil return pipe | 1 |

| 16 | Q1821090 | Hexagon flange stud bolt | 2 |

| 17 | 1112306-29D | Injector gasket | 6 |

| 18 | 1112010-31E (1112010-610-0000J.) | Injecteur | 6 |

| 19 | 1112014-29D | Joint torique | 6 |

| 20 | 1112013-29D | Injector presser plate | 6 |

| 21 | GB 849 8 | Spherical gasket | 6 |

| 22 | 1112011-29D | Injector presser plate | 6 |

| 23 | 1112030-29D | High pressure pipe joint assy | 6 |

| 24 | 1112032-29D | Joint torique | 6 |

| 25 | 1112031-29D | Intermediate pressure sealing ring – high pressure pipe joint | 6 |

| 26 | 1104030-29D | Assy de tuyau de carburant (je) | 1 |

| 27 | CQ72312T5 | Joint | 2 |

| 28 | 1111069-29D | Clamping bolt | 1 |

| 29 | 1104040-29D | Assy de tuyau de carburant (II) | 1 |

| 30 | 1111 055-29D | Turbocharger fuel pipe assy | 1 |

| 31 | 1111102-29D | Bracket-fuel injection pump | 1 |

| 32 | Q1841025 | Boulon à bride hexagonale | 2 |

| 33 | Q1841020 | Boulon à bride hexagonale | 2 |

| 34 | 1111101-31E (1111101-63J.-0000) | Support-fuel injection pump | 1 |

| 35 | 1129010-31E (1129010A63J-0000) | First high-pressure fuel pipe assy | 1 |

| 36 | 1129020-31E (1129020A63J-0000) | Second high-pressure fuel pipe assy | 1 |

| 37 | 1129030-31E (1129030A63J-0000) | Third high-pressure fuel pipe assy | 1 |

| 38 | 1129040-31E (1129040A63J-0000) | Fourth high-pressure fuel pipe assy | 1 |

| 39 | 1129050-31E (1129050A63J-0000) | Fifth high-pressure fuel pipe assy | 1 |

| 40 | 1129060-31E (1129060A63J-0000) | Sixth high-pressure fuel pipe assy | 1 |

| 41 | 1129100-29D | High-pressure fuel pipe clip assy (je) | 1 |

| 42 | 1129150-29D | High-pressure fuel pipe clip assy (Vi) | 1 |

| 43 | 1129130-29D | High-pressure fuel pipe clip assy (IV) | 1 |

| 44 | 1129123-29D | High-pressure fuel pipe base plate (III) | 1 |

| 45 | 1129127-29D | High-pressure fuel pipe presser plate (III) | 1 |

| 46 | 1129129-29D | High-pressure fuel pipe gasket (III) | 1 |

| 47 | 1129110-29D | High-pressure fuel pipe clip assy (II) | 1 |

| 48 | 1129140-29D | High-pressure fuel pipe clip assy (V) | 1 |

| 49 | 1117010-29D | Rotary-style hand-priming pump assy | 1 |

| 50 | CQ1460810 | Boulon combiné | 5 |

Les spécifications pour le Système d'alimentation en carburant FAW J6P are defined by its function as a high-pressure common rail (Hpcr) système d'injection.

| Demande de véhicule | FAW Jiefang CA3250P66K2L1T1E 6×4 Tombereau |

| Groupe système | Système d'alimentation en carburant FAW J6P (Hpcr) |

| Type de système | Rail commun haute pression (Hpcr) |

| Logique primaire | Pressurization (Pump), Stockage (Rail), Atomization (Injecteur) |

| High Pressure Pump | ‘Fuel injection pump assy’ (1111010C31E) |

| Pump Drive System | ‘Fuel injector drive gear’ (1111216-59D) – Entraîné par engrenage |

| Injector Component | ‘Injector’ (1112010-31E) – Quantité 6 |

| Étanchéité de l'injecteur (Combustion) | ‘Injector gasket’ (1112306-29D) – Quantité 6 |

| Injector Clamping | ‘Injector presser plate’ (1112013-29D) – Quantité 6 |

| High Pressure Lines | ‘High-pressure fuel pipe assy’ (1129010… à …060-31E) – Quantité 6 |

| Line Securing System | ‘High-pressure fuel pipe clip/base/gasket’ (11291xx-29D series) |

| Filtration & Priming | ‘Fuel filter assy’ (1012010-36D), ‘Hand-priming pump’ (1117010-29D) |

| Système de retour | ‘Fuel injector return pipe assy’ (1104050-29D) |

Pièces FAW, y compris l'ensemble bloc-cylindres, sont emballés avec soin pour garantir une livraison en toute sécurité. Chaque composant est sécurisé dans des matériaux de protection pour éviter tout dommage pendant le transport. Le réseau logistique garantit des expéditions ponctuelles dans le monde entier, soutenir des opérations de maintenance efficaces. Vous trouverez ci-dessous une image illustrant l'emballage standard des pièces de camion FAW., mettant en valeur l’attention portée aux détails dans la manipulation et le stockage.

Cette approche d'emballage minimise le risque de corrosion ou de dommages causés par les chocs., s'assurer que les pièces comme l'ensemble bloc-cylindres FAW arrivent en parfait état. Les clients peuvent compter sur la logistique de FAW pour une qualité et une fiabilité constantes.