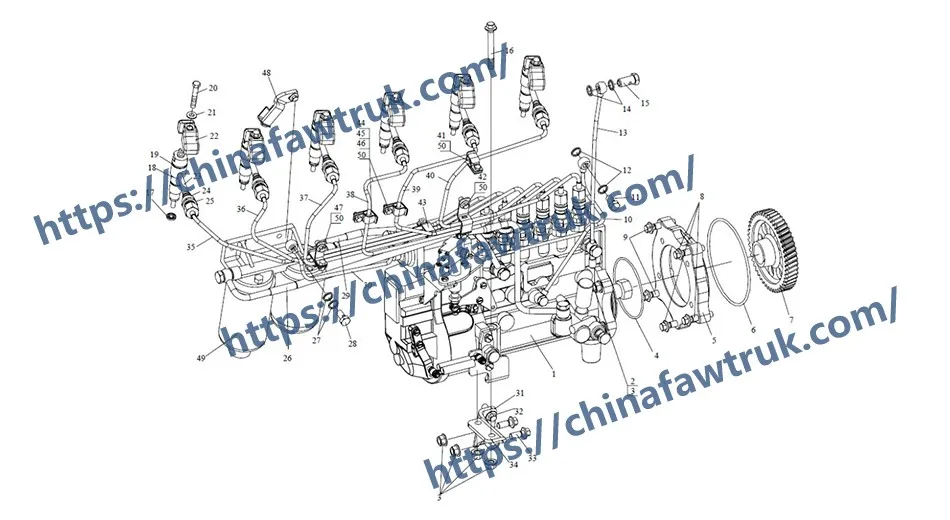

Добро пожаловать на эту экспертную деконструкцию Система подачи топлива FAW J6P (Глава 23). Это полный “Common Rail высокого давления” (HPCR) сборка для FAW Jiefang CA3250P66K2L1T1E 6×4 самосвал.

Это не простой топливопровод; это комплекс “Логическая сборка” из 50 типы компонентов, созданный для одной цели: создавать и контролировать огромное давление.

The “логика” этого Система подачи топлива FAW J6P это забрать топливо, отфильтровать это, надавить на него слишком сильно 25,000 пси, и ввести его как микроскопический, распыленный туман непосредственно в цилиндры в ту микросекунду, которая необходима.

The “Логика Common Rail” это то, что определяет это Система подачи топлива FAW J6P. В отличие от старых систем, «Топливный насос высокого давления»’ (Комп 1) не *время* инъекции; это только “создает давление.” Это огромное давление сохраняется в “Common Rail” (трубы высокого давления, Комп 35-42). Этот “логика” позволяет «Инжекторы’ (Комп 18) иметь электронное управление, не зависит от насоса. Этот “Логика многократных инъекций” (стрельба несколькими, крошечные впрыски за рабочий ход) это то, что обеспечивает бесшумную работу двигателя, его низкий крутящий момент, его топливная экономичность, и низкий уровень выбросов.

Это экспертное руководство является важным ресурсом для специалистов по двигателям., специалисты по топливным системам, и менеджеры по запчастям. Мы разложим всю группу из 50 компонентов на четыре основных. “логика” система: а “Низкое давление & Логика фильтрации” (подкачивающий насос и фильтр), а “Логика генерации высокого давления” (главный ТНВД), а “Логика распределения высокого давления” (трубы Common Rail), и критический “Инъекция & Возвратная логика” (форсунки и обратка). Это полное руководство по Система подачи топлива FAW J6P.

Эта группа “логика” это выкачать топливо из бака, “основной” система, и предоставить “Абсолютная фильтрация” прежде чем топливо достигнет дорогого насоса высокого давления.

1. Компонент: 'Роторный ручной подкачивающий насос в сборе’ (1117010-29Д)

Этот (Комп 49) это “Логика обслуживания.” The Система подачи топлива FAW J6P является “самокровотечение” во время нормальной работы, но после замены фильтра, линии полны воздуха. Этот “ручное грунтование” насос “логика” заключается в том, чтобы позволить технику вручную *вытягивать* топливо из бака, *протолкните* его через «Топливный фильтр»’ (Комп 28), и *выпустить* весь воздух из системы. Запуск двигателя при наличии воздуха в магистралях может привести к повреждению насоса высокого давления..

2. Компонент: 'Топливный фильтр в сборе’ (1012010-36Д)

Этот (Комп 28) это “Логика защиты системы.” Это “привратник” на весь Система подачи топлива FAW J6P. Common Rail высокого давления (HPCR) компоненты имеют допуски, измеряемые в *микронах*. Одна песчинка или капля воды *мгновенно* разрушит топливный насос высокого давления.’ (Комп 1) или «Инжекторы’ (Комп 18). Этот “Абсолютная логика фильтрации” означает, что этот фильтр необходимо удалить 99.9% всей воды (через встроенный сепаратор) и все твердые частицы вплоть до 2-5 микроны. Дешевый, некачественный фильтр – причина номер один Система подачи топлива FAW J6P отказ.

Эта группа представляет “мышца” принадлежащий Система подачи топлива FAW J6P. Его единственная функция — генерировать более 25,000 PSI давления топлива.

1. Компонент: 'Топливный насос высокого давления в сборе’ (1111010C31E)

Этот (Комп 1) это “Логика давления.” Это высокоточный, “положительное смещение” насос (скорее всего 3-поршневой радиальный насос). Это занимает “низкого давления” (60-90 пси) топливо из фильтра (Комп 28) и сжимает его до огромных размеров 25,000+ пси. Его “самосмазка” Логика в том, что он использует само дизельное топливо в качестве *единственной* смазки.. Это еще одна причина, по которой «Топливный фильтр»’ (Комп 28) это так критично.

2. Компонент: «Привод топливной форсунки’ (1111216-59Д)

Этот (Комп 7) это “Логика привода.” Этот насос высокого давления не электрический.. Это “с зубчатым приводом” непосредственно из внутренней части двигателя “Зубчатая передача.” Этот “Логика зубчатого привода” является а “срок службы двигателя” решение, как есть 100% надежный и идеально синхронизированный с вращением двигателя.

3. Компоненты: ‘Опорный ТНВД’ (1111101-31Э) & «Кронштейн’ (1111102-29Д)

Эти скобки (Комп 31 & 34) являются “Логика выравнивания.” «Приводная шестерня’ (Комп 7) должен *идеально* совпадать с зубчатым колесом двигателя. Эти сверхмощные, литые кронштейны крепятся болтами к блоку двигателя и обеспечивают жесткую, точно обработанный монтажный фланец, гарантирующий идеальное выравнивание.

4. Компоненты: 'Трубка смазочного масла в сборе’ (1104060-29Д) & «Полый болт’ (1104066-367)

Этот (Комп 10 & 11) это “Логика смазки насоса.” В то время как *насосная* сторона насоса HPCR смазывается топливом., его “водить машину” сторона (со своими подшипниками и распределительным валом) смазывается *моторным маслом*. Эта трубка “логика” это “кран” очистите масло из блока двигателя и подайте его непосредственно к подшипникам насоса, обеспечение его длительной долговечности. Это важнейшее звено для Система подачи топлива FAW J6P.

Эта группа образует “Общий рельс” сам. Его “логика” заключается в том, чтобы действовать как “резервуар под давлением” или “аккумулятор,” хранение 25,000+ PSI от насоса и распределение его на все шесть форсунок..

1. Компоненты: ‘Топливная трубка высокого давления в сборе’ (Цил 1-6) (1129010… к …1129060-31Э)

Эти (Комп 35-40) шесть человек “линии инжекторов.” Это самые ответственные трубы в Система подачи топлива FAW J6P. Их “логика” является “Идентичная длина.” Они *все* точно согнуты и имеют одинаковую длину.. Это очень важно. Если бы одна труба была короче, а “волны давления” от форсунки работа будет отличаться, вызывая Сила 1 чтобы получить другое давление “пульс” чем Сил 6. Сделав их идентичными, а “логика волны давления” сбалансирован, обеспечение *точного* одинакового топлива в каждый цилиндр, для гладкого, сбалансированный двигатель.

2. Компоненты: «Хомутик/основание/прокладка топливной трубки высокого давления’ (1129100-29Д, и т. д.)

Эта группа (Комп 41-48) это “ШВХ & Логика безопасности.” Шесть труб высокого давления (Комп 35-40) “пульсировать” яростно при каждой инъекции. Если разрешено касаться друг друга или двигателя, они бы “раздражать,” вибрировать, и разработать “усталостная трещина.” Утечка топлива под высоким давлением 25,000 PSI не является “капать”— это *атомизированный*, легковоспламеняющийся туман, который мгновенно вызовет масштабный пожар в двигателе.. The “логика” Эти зажимы и кронштейны должны удерживать каждую трубу абсолютно жесткой и изолированной., предотвращение этого критического сбоя в Система подачи топлива FAW J6P.

Эта последняя группа “логика” заключается в выполнении “финальное событие”: впрыск топлива под высоким давлением в цилиндр.

1. Компонент: «Инжектор’ (1112010-31Э)

Этот (Комп 18) это “Логика атомизации.” Это высокоскоростной, с электронным управлением (соленоид или пьезоэлектрический) игольчатый клапан. Когда ЭБУ дает команду, он открывается на несколько *микросекунд*. The 25,000+ Давление PSI заставляет топливо проходить через микроскопические отверстия в сопле., “распыление” он превращается в пар, который мгновенно воспламеняется для максимальной мощности..

2. The “Уплотнение” Логика: «Прокладка форсунки’ (1112306-29Д) & 'Уплотнительное кольцо’ (1112014-29Д)

Инжектор (Комп 18) должен быть запечатан от двух вещей. «Прокладка»’ (Комп 17) это медь “раздавить шайбу” внизу. Его “логика” заключается в том, чтобы запечатать 2000+ PSI *давления сгорания* на выходе. Уплотнительное кольцо’ (Комп 19) это резиновый уплотнитель сверху. Его “логика” заключается в герметизации низкого давления “возврат топлива” *в*, предотвращение вытекания топлива на горячий двигатель.

3. The “Зажим” Логика: «Прижимная пластина форсунки’ (1112013-29Д) & 'Болт’ (1112011-29Д)

Этот “Логика зажима” это то, что удерживает форсунку в отверстии. «Болт»’ (Комп 21) подтягивается к прижимной пластине’ (Комп 20), который вращается и создает высокую “вниз” усилие на форсунке. Эта сила – это то, что “давит” «Прокладка»’ (Комп 17) для создания герметичного уплотнения.

4. The “Возвращаться” Логика: 'Обратный трубопровод топливной форсунки в сборе’ (1104050-29Д)

Этот (Комп 13) это “Логика байпасного охлаждения.” Насос HPCR и форсунки “обойти” большое количество топлива для охлаждения и смазки собственных движущихся частей. Эта «обратная труба»’ “логика” это все это собрать “использовал” топливо из форсунок и насоса и безопасно направьте его обратно в топливный бак.. Это жизненно важная часть Система подачи топлива FAW J6Pтермический менеджмент.

В следующей таблице представлена полная, подробная разбивка всех 50 типы компонентов в Система подачи топлива FAW J6P для FAW Jiefang CA3250P66K2L1T1E 6×4 самосвал.

| Отметка | Часть №. | Наименование | Количество |

|---|---|---|---|

| 1 | 1111010C31E (1111010-675-0000ТД) | Аспирация насоса впрыскивания топлива | 1 |

| 2 | CQ1201030 | Двусторонняя шпилька | 4 |

| 3 | CQ39610 | Шестигранная фланцевая гайка | 4 |

| 4 | CQ73421000C | Уплотнительное кольцо для пневматики | 1 |

| 5 | 1111228-30Э (1111228-633-0000) | Обратный клапан – топливный насос | 1 |

| 6 | CQ73421500C | Уплотнительное кольцо для пневматики | 1 |

| 7 | 1111216-59Д (1111216-630-0000) | Шестерня привода топливной форсунки | 1 |

| 8 | Q1841045 | Шестигранный фланцевый болт | 3 |

| 9 | Q1841030 | Шестигранный фланцевый болт | 2 |

| 10 | 1104060-29Д | Трубка смазочного масла в сборе | 1 |

| 11 | 1104066-367 | Полый болт – смазочная масляная трубка в сборе | 1 |

| 12 | CQ72310T5 | Прокладка | 1 |

| 13 | 1104050-29Д | Обратный трубопровод топливной форсунки в сборе | 1 |

| 14 | CQ72314T5 | Прокладка | 2 |

| 15 | 1104073-D6 | Полый болт – трубка возврата масла | 1 |

| 16 | Q1821090 | Шпилька с шестигранным фланцем | 2 |

| 17 | 1112306-29Д | Прокладка форсунки | 6 |

| 18 | 1112010-31Э (1112010-610-0000Дж) | Инжектор | 6 |

| 19 | 1112014-29Д | уплотнительное кольцо | 6 |

| 20 | 1112013-29Д | Прижимная пластина форсунки | 6 |

| 21 | ГБ 849 8 | Сферическая прокладка | 6 |

| 22 | 1112011-29Д | Прижимная пластина форсунки | 6 |

| 23 | 1112030-29Д | Узел соединения труб высокого давления в сборе | 6 |

| 24 | 1112032-29Д | уплотнительное кольцо | 6 |

| 25 | 1112031-29Д | Уплотнительное кольцо промежуточного давления – соединение труб высокого давления | 6 |

| 26 | 1104030-29Д | Топливная труба обшивка (я) | 1 |

| 27 | CQ72312T5 | Прокладка | 2 |

| 28 | 1111069-29Д | Зажимной болт | 1 |

| 29 | 1104040-29Д | Топливная труба обшивка (II) | 1 |

| 30 | 1111 055-29Д | Топливопровод турбокомпрессора в сборе | 1 |

| 31 | 1111102-29Д | Кронштейн-ТНВД | 1 |

| 32 | Q1841025 | Шестигранный фланцевый болт | 2 |

| 33 | Q1841020 | Шестигранный фланцевый болт | 2 |

| 34 | 1111101-31Э (1111101-63Дж-0000) | Опорный топливный насос высокого давления | 1 |

| 35 | 1129010-31Э (1129010A63J-0000) | Первый топливный трубопровод высокого давления в сборе | 1 |

| 36 | 1129020-31Э (1129020A63J-0000) | Второй топливный трубопровод высокого давления в сборе | 1 |

| 37 | 1129030-31Э (1129030A63J-0000) | Третий топливный трубопровод высокого давления в сборе | 1 |

| 38 | 1129040-31Э (1129040A63J-0000) | Четвертый топливный трубопровод высокого давления в сборе | 1 |

| 39 | 1129050-31Э (1129050A63J-0000) | Пятый топливный трубопровод высокого давления в сборе | 1 |

| 40 | 1129060-31Э (1129060A63J-0000) | Шестой топливный трубопровод высокого давления в сборе | 1 |

| 41 | 1129100-29Д | Хомут топливной трубки высокого давления в сборе (я) | 1 |

| 42 | 1129150-29Д | Хомут топливной трубки высокого давления в сборе (VI) | 1 |

| 43 | 1129130-29Д | Хомут топливной трубки высокого давления в сборе (IV) | 1 |

| 44 | 1129123-29Д | Опорная пластина топливного трубопровода высокого давления (III) | 1 |

| 45 | 1129127-29Д | Прижимная пластина топливной трубки высокого давления (III) | 1 |

| 46 | 1129129-29Д | Прокладка топливной трубки высокого давления (III) | 1 |

| 47 | 1129110-29Д | Хомут топливной трубки высокого давления в сборе (II) | 1 |

| 48 | 1129140-29Д | Хомут топливной трубки высокого давления в сборе (В) | 1 |

| 49 | 1117010-29Д | Роторный ручной подкачивающий насос в сборе | 1 |

| 50 | CQ1460810 | Комбинированный болт | 5 |

Технические характеристики Система подачи топлива FAW J6P определяются по своей функции в качестве общей магистрали высокого давления. (HPCR) система впрыска.

| Приложение для автомобиля | FAW Цзефан CA3250P66K2L1T1E 6×4 Самосвал |

| Системная группа | Система подачи топлива FAW J6P (HPCR) |

| Тип системы | Common Rail высокого давления (HPCR) |

| Первичная логика | Наддув (Насос), Хранилище (Железнодорожный), Распыление (Инжектор) |

| Насос высокого давления | 'Топливный насос высокого давления в сборе’ (1111010C31E) |

| Система привода насоса | «Привод топливной форсунки’ (1111216-59Д) – с зубчатым приводом |

| Компонент инжектора | «Инжектор’ (1112010-31Э) – Кол-во 6 |

| Уплотнение инжектора (Горение) | «Прокладка форсунки’ (1112306-29Д) – Кол-во 6 |

| Зажим форсунки | «Прижимная пластина форсунки’ (1112013-29Д) – Кол-во 6 |

| Линии высокого давления | ‘Топливная трубка высокого давления в сборе’ (1129010… к …060-31Э) – Кол-во 6 |

| Система крепления линии | «Хомутик/основание/прокладка топливной трубки высокого давления’ (11291серия хх-29Д) |

| Фильтрация & Грунтовка | 'Топливный фильтр в сборе’ (1012010-36Д), «Ручной насос’ (1117010-29Д) |

| Система возврата | 'Обратный трубопровод топливной форсунки в сборе’ (1104050-29Д) |

Запчасти ФАВ, включая блок цилиндров в сборе, тщательно упакованы, чтобы обеспечить безопасную доставку. Каждый компонент закреплен защитными материалами для предотвращения повреждений при транспортировке.. Логистическая сеть гарантирует своевременную доставку по всему миру., поддержка эффективных операций по техническому обслуживанию. Ниже приведено изображение, иллюстрирующее стандартную упаковку запчастей для грузовиков FAW., демонстрация внимания к деталям в обращении и хранении.

Такой подход к упаковке сводит к минимуму риск коррозии или ударного повреждения., обеспечение доставки таких деталей, как блок цилиндров FAW в сборе, в идеальном состоянии.. Клиенты могут положиться на логистику FAW для обеспечения стабильного качества и надежности..