Bienvenue dans cette analyse technique définitive du FAW J6P Couvre-culasse (Main Assy P/N 1003031A600-000Z). C'est le primaire “service door” for the engine on the FAW Jiefang CA3250P66K2L1T1E 6×4 tombereau.

This component is often mistaken for a simple “couvercle,” but it is a complex, ingéré “Assemblage logique” that is critical to engine health.

Its primary logic is twofold: it provides the final “Logique d'étanchéité” for the entire engine, keeping high-pressure oil in and all contaminants out. Deuxièmement, it is the core of the engine’s “Oil Control Logic,” housing the baffle system that manages crankcase vapors. Ce FAW J6P Couvre-culasse is essential for a clean, sans fuite, and efficient engine.

Le “Scellage & Logique NVH” de la FAW J6P Couvre-culasse is its most obvious function. C'est la finale “roof” over the valvetrain. A failure of its ‘Seal ring’ (joint) is the most common source of engine oil leaks, which can damage belts and alternators below. C'est “Logique NVH” (Bruit, Vibration, Dureté) est également critique. The cover is often made from a composite material or stamped steel with damping properties, designed specifically to absorb and muffle the high-frequency “bruit” of the valvetrain, reducing operator fatigue in the cab.

This expert guide is an essential resource for fleet technicians, engine specialists, et gestionnaires de pièces. We will deconstruct the entire 5-component-type group. Nous analyserons le “Main Cover & Nvh” logique (the cover itself), la critique “Oil Baffle & PCV” logique (the internal ‘baffle plate’), et le “Scellage & Attache” logic that ensures a perfect, longue durée, vibration-proof seal for the FAW J6P Couvre-culasse.

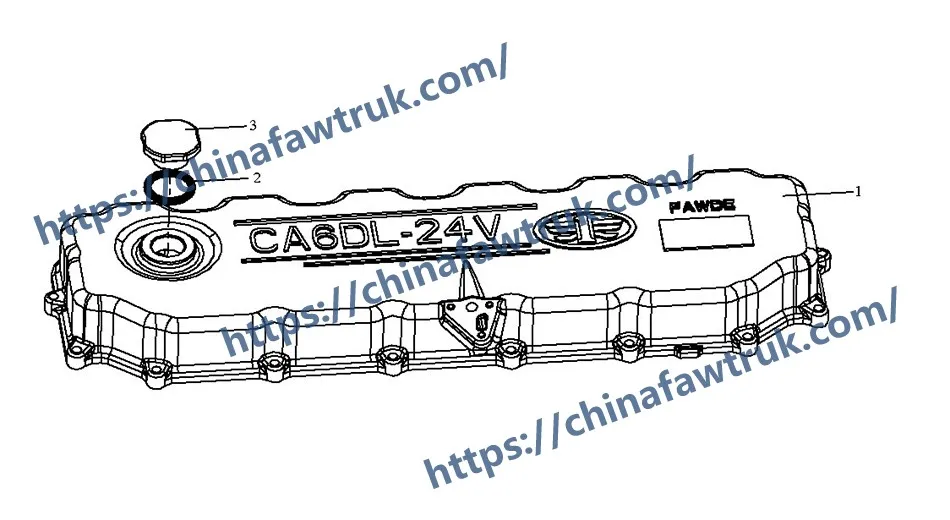

This component is the primary structural part of the assembly, the main cover itself.

1. Composant: ‘Cylinder head cover’ (1003031A600-000Z)

This is the main body of the FAW J6P Couvre-culasse. C'est “logique” is to be a lightweight, yet perfectly rigid and flat “toit.” It is typically made from either a high-temperature composite plastic or a stamped steel alloy. Le “logique structurelle” of this design is to provide a perfectly flat and stable sealing surface that will not warp under the engine’s intense heat cycles. Warping is the primary enemy of a good seal, so the cover is often designed with reinforcing ribs.

C'est la deuxième “logique” est “Contrôle NVH” (Bruit, Vibration, Dureté). A simple metal plate would act like a drum, amplifying the “bruit” of the valvetrain (rocker arms and injectors). Ce FAW J6P Couvre-culasse is engineered to dampen those specific frequencies, often by using a composite “sandwich” material or by being “isolated” from the head by rubber-grommeted bolts. This is a key “logique de confort” composant, reducing the noise that reaches the operator in the cab and improving driver focus. It also serves as the main barrier protecting the valvetrain from external contaminants.

This is arguably the most complex and critical “logique” in the entire FAW J6P Couvre-culasse assemblée. It is not just a splash guard.

1. Composant: ‘Oil baffle assy’ (1003035-600-000Z)

Ce composant, the ‘Oil baffle assy’, is the heart of the engine’s “Ventilation positive du carter” (PCV) système. Voici le “PCV Logic”: All engines have “soufflé,” which is combustion gas that escapes past the piston rings into the crankcase. This gas must be vented, but it is mixed with a heavy “mist” of hot oil. Le “logique” of this baffle is to be a “maze.”

The blow-by gas, on its way to the PCV valve (which is usually on the cover), is forced to travel through this baffle. The gas itself can make the sharp turns, but the heavier liquid oil droplets cannot. They have too much inertia. Ils “impact” on the walls of the baffle, “se fondre” (form into larger drops), and then drip back down onto the valvetrain for lubrication. The now “faire le ménage” gaz (mostly vapor) exits the PCV valve and is fed back into the engine’s intake to be burned. Ce “Baffle Logic” c'est ce qui fait que FAW J6P Couvre-culasse an active emissions-control and efficiency device.

If this baffle fails or becomes clogged, le “logique” breaks. Liquid oil will be sucked into the engine’s intake, leading to blue smoke, high oil consumption, and rapid carbon buildup on the intake valves and turbocharger. Donc, this ‘baffle’ is a critical component of the FAW J6P Couvre-culasse.

This group contains the components that physically seal the FAW J6P Couvre-culasse and provide service access.

1. Composant: ‘Seal ring’ (1003036-29D)

This is the main perimeter gasket. C'est “logique” est “controlled compression.” It is not a flat paper gasket but an engineered “elastomer” (haute température, oil-resistant rubber) joint. It is designed to sit in a groove in the FAW J6P Couvre-culasse or the head itself. When the bolts are tightened, the gasket compresses to fill the groove perfectly, creating a 360-degree, durable, oil-tight seal that can flex and move with the engine’s vibrations.

2. Composant: 'Couverture’ (1003037-29D)

C'est le “Service Access Logic,” commonly known as the oil filler cap. C'est “logique” is to provide a reliable, tool-free access point for adding engine oil. It must provide a perfect seal to prevent oil splash and crankcase vapor leaks, which it does via its own integrated O-ring or gasket. It is a critical part of the FAW J6P Couvre-culasse‘s user interface.

3. Composant: « Boulon à bride hexagonale’ (Q1840510)

C'est le “Logique de force de serrage.” La liste réclame 12 de ces boulons. Le “flange logic” est critique: the flange is a built-in washer. This distributes the clamping load from the bolt head over a wider area of the composite or stamped-steel cover, preventing it from cracking. These bolts are often designed with “shoulders” (a specific unthreaded section) that act as a “stop.” Ce “stop logic” prevents over-tightening, which would crush and destroy the ‘Seal ring’ (Comp 2). Le “torque logic” est également vital; ces 12 bolts must be tightened in a specific sequence (Par exemple, center-out) to ensure the FAW J6P Couvre-culasse gasket seats evenly.

Le tableau suivant fournit l'intégralité, ventilation détaillée de tous 5 types de composants identifiés dans ce FAW J6P Couvre-culasse groupe pour le FAW Jiefang CA3250P66K2L1T1E 6×4 tombereau.

| Marque | Partie no. | Nom de la pièce | Quantité |

|---|---|---|---|

| 1 | 1003031A600-000Z 1003035-600-000Z Q1840510 |

Cylinder head cover Oil baffle assy Boulon à bride hexagonale |

1 1 12 |

| 2 | 1003036-29D | Bague d'étanchéité | 1 |

| 3 | 1003037-29D | Couverture | 1 |

Les spécifications pour le FAW J6P Couvre-culasse are defined by its function as the primary sealing and ventilation component for the valvetrain.

| Demande de véhicule | FAW Jiefang CA3250P66K2L1T1E 6×4 Tombereau |

| Groupe système | FAW J6P Couvre-culasse Assemblée |

| Main Cover Part No. | 1003031A600-000Z |

| Logique primaire | Valvetrain Sealing & Protection, NVH Damping |

| Logique secondaire | Ventilation du carter (PCV), Oil/Gas Separation |

| Key Sub-Assembly | ‘Oil baffle assy’ (1003035-600-000Z) |

| Main Gasket Type | ‘Seal ring’ (1003036-29D) – Engineered Elastomer |

| Système de fixation | « Boulon à bride hexagonale’ (Q1840510) – Quantité 12 |

| Service Access | 'Couverture’ (1003037-29D) – Oil Filler Cap |

| Système associé | Complet FAW J6P Couvre-culasse |

Pièces FAW, y compris l'ensemble bloc-cylindres, sont emballés avec soin pour garantir une livraison en toute sécurité. Chaque composant est sécurisé dans des matériaux de protection pour éviter tout dommage pendant le transport. Le réseau logistique garantit des expéditions ponctuelles dans le monde entier, soutenir des opérations de maintenance efficaces. Vous trouverez ci-dessous une image illustrant l'emballage standard des pièces de camion FAW., mettant en valeur l’attention portée aux détails dans la manipulation et le stockage.

Cette approche d'emballage minimise le risque de corrosion ou de dommages causés par les chocs., s'assurer que les pièces comme l'ensemble bloc-cylindres FAW arrivent en parfait état. Les clients peuvent compter sur la logistique de FAW pour une qualité et une fiabilité constantes.