Bienvenidos a este análisis técnico definitivo del Tapa de culata FAW J6P (Main Assy P/N 1003031A600-000Z). Este es el principal “service door” para el motor en FAW Jiefang CA3250P66K2L1T1E 6×4 camión volcado.

This component is often mistaken for a simple “tapa,” but it is a complex, diseñado “Asamblea lógica” that is critical to engine health.

Its primary logic is twofold: it provides the final “Lógica de sellado” para todo el motor, keeping high-pressure oil in and all contaminants out. En segundo lugar, it is the core of the engine’s “Lógica de control de aceite,” housing the baffle system that manages crankcase vapors. Este Tapa de culata FAW J6P is essential for a clean, sin fugas, and efficient engine.

El “Sellando & Lógica NVH” del Tapa de culata FAW J6P es su función más obvia. es la final “techo” over the valvetrain. A failure of its ‘Seal ring’ (empaquetadora) is the most common source of engine oil leaks, which can damage belts and alternators below. Es “Lógica NVH” (Ruido, Vibración, Dureza) también es crítico. The cover is often made from a composite material or stamped steel with damping properties, designed specifically to absorb and muffle the high-frequency “clatter” del tren de válvulas, reducing operator fatigue in the cab.

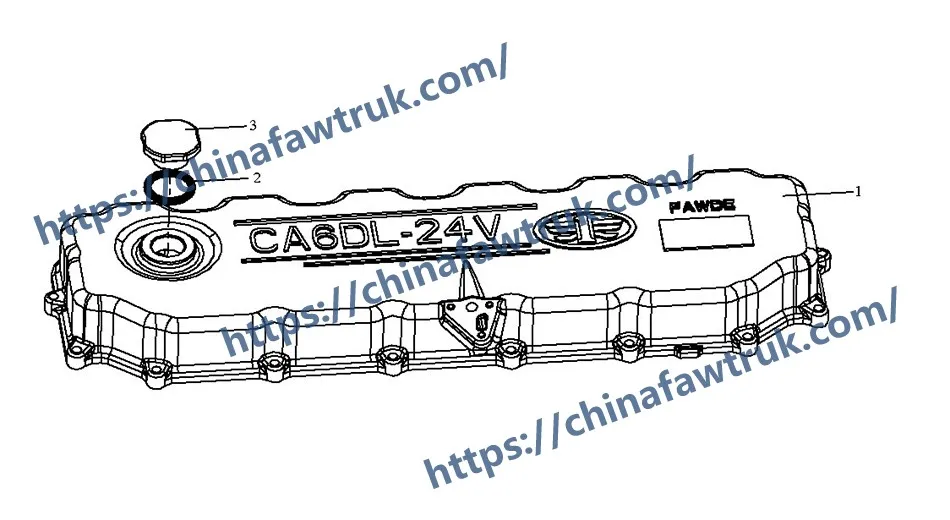

This expert guide is an essential resource for fleet technicians, engine specialists, y gerentes de repuestos. Deconstruiremos todo el grupo tipo 5 componentes.. Analizaremos el “Main Cover & Nvh” lógica (the cover itself), el critico “Oil Baffle & PCV” lógica (the internal ‘baffle plate’), y el “Sellando & Cierre” logic that ensures a perfect, long-lasting, vibration-proof seal for the Tapa de culata FAW J6P.

This component is the primary structural part of the assembly, the main cover itself.

1. Componente: ‘Cylinder head cover’ (1003031A600-000Z)

This is the main body of the Tapa de culata FAW J6P. Es “lógica” is to be a lightweight, yet perfectly rigid and flat “roof.” It is typically made from either a high-temperature composite plastic or a stamped steel alloy. El “lógica estructural” of this design is to provide a perfectly flat and stable sealing surface that will not warp under the engine’s intense heat cycles. Warping is the primary enemy of a good seal, so the cover is often designed with reinforcing ribs.

su segundo “lógica” es “Control NVH” (Ruido, Vibración, Dureza). A simple metal plate would act like a drum, amplifying the “clatter” del tren de válvulas (rocker arms and injectors). Este Tapa de culata FAW J6P is engineered to dampen those specific frequencies, often by using a composite “sándwich” material or by being “aislado” from the head by rubber-grommeted bolts. Esta es una clave “lógica de confort” componente, reducing the noise that reaches the operator in the cab and improving driver focus. It also serves as the main barrier protecting the valvetrain from external contaminants.

This is arguably the most complex and critical “lógica” in the entire Tapa de culata FAW J6P asamblea. It is not just a splash guard.

1. Componente: ‘Oil baffle assy’ (1003035-600-000z)

este componente, the ‘Oil baffle assy’, is the heart of the engine’s “Positive Crankcase Ventilation” (PCV) sistema. Aquí está el “PCV Logic”: All engines have “explosión,” which is combustion gas that escapes past the piston rings into the crankcase. This gas must be vented, but it is mixed with a heavy “neblina” de aceite caliente. El “lógica” of this baffle is to be a “maze.”

The blow-by gas, on its way to the PCV valve (which is usually on the cover), is forced to travel through this baffle. The gas itself can make the sharp turns, but the heavier liquid oil droplets cannot. They have too much inertia. Ellos “impacto” on the walls of the baffle, “juntarse” (form into larger drops), and then drip back down onto the valvetrain for lubrication. The now “limpio” gas (mostly vapor) exits the PCV valve and is fed back into the engine’s intake to be burned. Este “Lógica deflectora” es lo que hace que Tapa de culata FAW J6P an active emissions-control and efficiency device.

If this baffle fails or becomes clogged, el “lógica” breaks. Liquid oil will be sucked into the engine’s intake, conduciendo al humo azul, alto consumo de aceite, and rapid carbon buildup on the intake valves and turbocharger. Por lo tanto, this ‘baffle’ is a critical component of the Tapa de culata FAW J6P.

This group contains the components that physically seal the Tapa de culata FAW J6P and provide service access.

1. Componente: ‘Seal ring’ (1003036-29D)

This is the main perimeter gasket. Es “lógica” es “controlled compression.” It is not a flat paper gasket but an engineered “elastomer” (alta temperatura, oil-resistant rubber) sello. It is designed to sit in a groove in the Tapa de culata FAW J6P or the head itself. When the bolts are tightened, the gasket compresses to fill the groove perfectly, creating a 360-degree, durable, oil-tight seal that can flex and move with the engine’s vibrations.

2. Componente: ‘Cover’ (1003037-29D)

Este es el “Service Access Logic,” commonly known as the oil filler cap. Es “lógica” is to provide a reliable, tool-free access point for adding engine oil. It must provide a perfect seal to prevent oil splash and crankcase vapor leaks, which it does via its own integrated O-ring or gasket. It is a critical part of the Tapa de culata FAW J6P‘s user interface.

3. Componente: «Perno de brida hexagonal’ (Q1840510)

Este es el “Lógica de la fuerza de sujeción.” La lista pide 12 de estos pernos. El “flange logic” es critico: the flange is a built-in washer. This distributes the clamping load from the bolt head over a wider area of the composite or stamped-steel cover, evitando que se agriete. These bolts are often designed with “shoulders” (a specific unthreaded section) that act as a “stop.” Este “stop logic” prevents over-tightening, which would crush and destroy the ‘Seal ring’ (compensación 2). El “torque logic” is also vital; estos 12 bolts must be tightened in a specific sequence (P.EJ., center-out) to ensure the Tapa de culata FAW J6P gasket seats evenly.

La siguiente tabla proporciona la información completa, desglose detallado de todos 5 tipos de componentes identificados en este Tapa de culata FAW J6P group for the FAW Jiefang CA3250P66K2L1T1E 6×4 camión volcado.

| Marca | Número de pieza. | Nombre de la pieza | Cantidad |

|---|---|---|---|

| 1 | 1003031A600-000Z 1003035-600-000z Q1840510 |

Cylinder head cover Oil baffle assy Perno de brida hexagonal |

1 1 12 |

| 2 | 1003036-29D | Anillo de sello | 1 |

| 3 | 1003037-29D | Cubrir | 1 |

Las especificaciones para el Tapa de culata FAW J6P are defined by its function as the primary sealing and ventilation component for the valvetrain.

| Solicitud de vehículo | FAW Jiefang CA3250P66K2L1T1E 6×4 Camión de la basura |

| Grupo de sistema | Tapa de culata FAW J6P Asamblea |

| Main Cover Part No. | 1003031A600-000Z |

| Lógica primaria | Valvetrain Sealing & Protección, Amortiguación NVH |

| Lógica secundaria | La ventilación del cárter (PCV), Separación de petróleo/gas |

| Key Sub-Assembly | ‘Oil baffle assy’ (1003035-600-000z) |

| Main Gasket Type | ‘Seal ring’ (1003036-29D) – Engineered Elastomer |

| Sistema de sujeción | «Perno de brida hexagonal’ (Q1840510) – Cantidad 12 |

| Service Access | ‘Cover’ (1003037-29D) – Tapa de llenado de aceite |

| Sistema asociado | Lleno Tapa de culata FAW J6P |

piezas FAW, incluido el conjunto del bloque de cilindros, Se empaquetan con cuidado para garantizar una entrega segura.. Cada componente está asegurado con materiales protectores para evitar daños durante el transporte.. La red logística garantiza envíos puntuales en todo el mundo., apoyando operaciones de mantenimiento eficientes. A continuación se muestra una imagen que ilustra el embalaje estándar de las piezas de camiones FAW., mostrando la atención al detalle en el manejo y almacenamiento.

Este enfoque de embalaje minimiza el riesgo de corrosión o daños por impacto., asegurando que piezas como el conjunto de bloque de cilindros FAW lleguen en perfectas condiciones. Los clientes pueden confiar en la logística de FAW para obtener calidad y confiabilidad constantes.