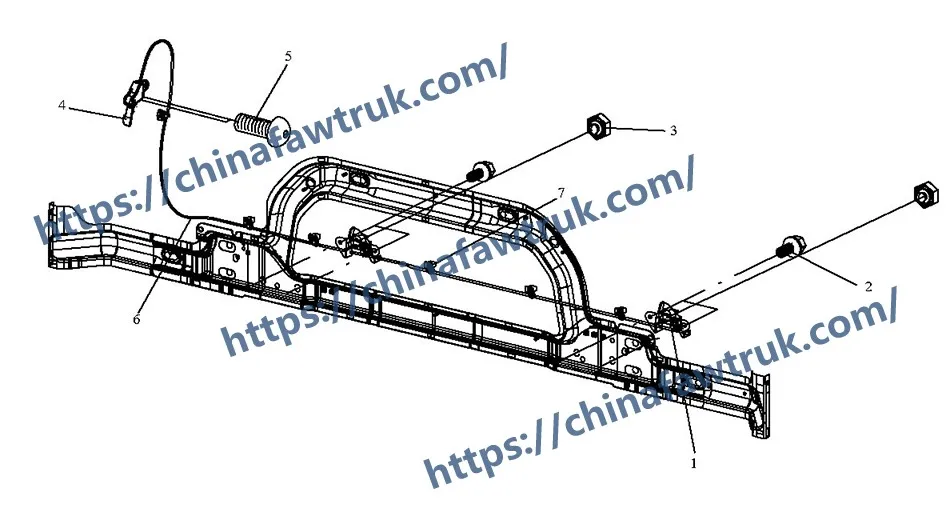

Il s'agit d'un guide technique complet sur le FAW J6P activer la poignée système (serrure du boîtier avant) Pour le FAW Jiefang CA3250P66K2L1T1E 6×4 tombereau. Cette déconstruction analyse 7 types de composants réparables, détaillant la poignée à distance, câble, loquets, et le matériel qui forment ce mécanisme d'accès et de sécurité critique.

Le FAW J6P activer la poignée fait référence au système complet utilisé pour déverrouiller le lourd panneau avant du boîtier (grille) de la conception J6P à cabine sur moteur. Ce système n'est pas un luxe; c'est un mécanisme essentiel pour les opérations quotidiennes. Il permet au conducteur de déverrouiller à distance les deux verrous principaux fixant la façade avant., lui permettant de pivoter pour les contrôles d'entretien de routine tels que l'inspection du liquide de refroidissement, liquide lave-glace, et niveaux d'huile.

Cette déconstruction analysera les trois groupes logiques fondamentaux du FAW J6P activer la poignée système: l'interface conducteur en cabine (la poignée elle-même), la liaison mécanique (le câble et les pinces), et le mécanisme de verrouillage (les corps de serrure et les goupilles). L’ensemble de cet ensemble doit être incroyablement robuste, car il doit maintenir le panneau avant en sécurité contre les forces du vent à vitesse élevée et les vibrations extrêmes hors route, tout en libérant en douceur et de manière fiable sur commande. Un échec dans le FAW J6P activer la poignée système peut conduire soit à un détachement rapide d'un panneau, soit à un, plus communément, un panneau grippé qui empêche l'accès critique au moteur, entraînant un arrêt du véhicule.

Ce groupe de composants représente le point de départ du FAW J6P activer la poignée système. C'est la seule partie du mécanisme avec laquelle le conducteur interagit directement.

1. Composant: « Ensemble de poignée d'ouverture’ (5302530-A01) – Quantité 1

Ce (Comp 4) est la poignée physique située à l'intérieur de la cabine, généralement dans le plancher du conducteur ou sous le tableau de bord. Le Logique ergonomique nécessite que ce composant soit durable, facilement accessible, et fournit suffisamment de levier mécanique pour que tout conducteur puisse facilement tirer et déverrouiller les verrous robustes.. Il est généralement constitué de matériaux à fort impact, plastique ABS renforcé.

2. Composant: « Vis à tête cylindrique à empreinte cruciforme’ (Q2140620F6) – Quantité 2

Ce (Comp 5) est le matériel utilisé pour monter l'ensemble de poignée d'ouverture’ (Comp 4) au panneau intérieur de la cabine. Bien qu'apparemment mineur, ces attaches sont essentielles. S'ils se détachent, l'ensemble de la poignée fléchira lorsqu'il sera tiré, plutôt que de transférer toute la force au câble. Cela donne le FAW J6P activer la poignée un “spongieux” ou “cassé” sentir et peut empêcher les verrous de se désengager complètement.

Un mode de défaillance courant pour cette partie du FAW J6P activer la poignée est-ce que la poignée en plastique elle-même se fissure à son point de pivotement après des années de traction répétée, surtout si le câble (Comp 6) devient raide ou grippé.

Cet ensemble de composants forme le lien mécanique, transmettre la traction du conducteur de la poignée montée sur la cabine aux mécanismes de verrouillage extérieurs. C'est le point de défaillance le plus courant dans le FAW J6P activer la poignée système.

1. Composant: 'Ensemble de câbles’ (5302550-A01) – Quantité 1

Ce (Comp 6) est le composant principal de la transmission. Le Logique de traction est-ce que ce câble (un fil intérieur en acier tressé à l'intérieur d'une gaine en plastique à faible friction) doit transmettre une force de traction sur une distance, souvent autour de plusieurs virages. La gaine est ancrée aux deux extrémités, permettant au fil intérieur de se déplacer librement. Il s'agit d'un élément essentiel du FAW J6P activer la poignée.

Le câble est très sensible à deux modes de défaillance principaux. Le premier est l'étirement, où le fil intérieur s'allonge de façon permanente avec le temps, créer “mou” dans le système et empêchant la poignée de tirer les loquets suffisamment loin pour les libérer. Deuxième, et plus commun, est en train de saisir. La gaine extérieure peut être irritée, permettant à l'eau et aux graviers d'entrer. Cela corrode le fil intérieur, le faisant se lier ou se saisir complètement, faire le FAW J6P activer la poignée inopérable.

2. Composant: « Pince à cravate II’ (3724012-A01) – Quantité 6

Ce (Comp 7) est sans doute le composant le plus critique pour la durée de vie du câble. Le Logique de prévention des frottements est vital. Ces six pinces fixent la gaine extérieure du câble (Comp 6) à la carrosserie et au châssis de la cabine. Ils empêchent le câble de vibrer, se tordre, ou en frottant contre des bords métalliques tranchants. Une seule pince manquante ou cassée peut permettre au câble de frotter, qui finira par porter un trou dans la gaine, conduisant à la corrosion et à la défaillance de l'ensemble FAW J6P activer la poignée système.

Ce groupe de composants constitue le principal mécanisme de sécurité du FAW J6P activer la poignée. Il s'agit de l'interface mécanique qui sécurise physiquement le panneau avant du boîtier..

1. Composant: « Ensemble de corps de serrure – boîtier avant’ (5302510-A01) – Quantité 2

Ce (Comp 1) est le mécanisme de verrouillage principal, utilisé par paire pour la redondance et la stabilité. Le Logique de verrouillage rotatif est une conception robuste: lorsque la « Goupille de verrouillage’ (Comp 3) entre, ça force un cliquet rotatif (came) tourner et se verrouiller derrière lui. Ce cliquet est maintenu en place par un ressort, Assurer le FAW J6P activer la poignée le système ne peut pas être secoué par les vibrations. Cet ensemble est monté sur la structure de la cabine.

2. Composant: « Ensemble de goupille de verrouillage – boîtier avant’ (5302540-A01) – Quantité 2

Ce (Comp 3) est le “gréviste” ou une épingle. Il est monté sur le panneau avant mobile du coffret. Cette goupille en acier trempé est conçue pour s'aligner parfaitement avec le corps de la serrure.’ (Comp 1). Le Logique d'alignement est critique; cette goupille doit guider le panneau lourd dans la position fermée exacte. Désalignement de ceci Serrure avant FAW J6P Le composant rendra le panneau difficile à fermer ou à trembler..

3. Composant: « Boulon combiné’ (CQ1460820F6) – Quantité 4

Ce (Comp 2) est le matériel utilisé pour monter le « corps de serrure »’ (Comp 1). Ce sont des boulons à bride qui répartissent la charge de serrage, et ils doivent être installés avec un composé frein-filet pour garantir qu'ils ne vibrent pas de manière lâche. Un corps de serrure desserré est une source courante de désalignement du panneau et de défaillance du FAW J6P activer la poignée système.

L'entretien de cette partie du FAW J6P activer la poignée implique de nettoyer périodiquement la vieille graisse et les débris du loquet (Comp 1) et appliquer une nouvelle couche de graisse blanche au lithium pour garantir que le cliquet bouge librement.

Le tableau suivant fournit l'intégralité, ventilation détaillée de tous 7 types de composants dans le FAW J6P activer la poignée (serrure du boîtier avant) assemblage pour le FAW Jiefang CA3250P66K2L1T1E 6×4 tombereau. Cette liste est indispensable pour commander des pièces de rechange et effectuer un service complet du FAW J6P activer la poignée.

| Marque | Partie no. | Nom de la pièce | Quantité |

|---|---|---|---|

| 1 | 5302510-A01 | Corps de serrure – boîtier avant | 2 |

| 2 | CQ1460820F6 | Boulon combiné | 4 |

| 3 | 5302540-A01 | Ensemble de goupille de verrouillage – boîtier avant | 2 |

| 4 | 5302530-A01 | Ensemble de poignée d'ouverture | 1 |

| 5 | Q2140620F6 | Vis de tête de casserole en retrait | 2 |

| 6 | 5302550-A01 | Ensemble de câbles | 1 |

| 7 | 3724012-A01 | Pince à cravate II | 6 |

Les spécifications pour le FAW J6P activer la poignée sont définis par sa fonction de télécommande, système de verrouillage robuste pour le panneau avant de l'enceinte de la cabine. Un bon fonctionnement FAW J6P activer la poignée est essentiel pour la sécurité.

| Demande de véhicule | FAW Jiefang CA3250P66K2L1T1E 6×4 Tombereau |

| Groupe système | FAW J6P activer la poignée (Système de verrouillage avant) |

| Logique primaire | Fixation du panneau avant du boîtier (grille) à la carrosserie de la cabine |

| Méthode d'actionnement | Tirage de câble mécanique à distance |

| Composant de verrouillage | « Ensemble de corps de serrure’ (5302510-A01) (Quantité 2) |

| Composant attaquant | « Ensemble de goupille de verrouillage’ (5302540-A01) (Quantité 2) |

| Mécanisme de libération | « Ensemble de poignée d'ouverture’ (5302530-A01) & 'Ensemble de câbles’ (5302550-A01) |

| Acheminement des câbles | « Pince à cravate II’ (3724012-A01) (Quantité 6) |

| Types de composants totaux | 7 |

| Système associé | Extérieur de la cabine / Systèmes de sécurité. Le FAW J6P activer la poignée est un dispositif de sécurité clé. |

Pièces FAW, y compris l'ensemble bloc-cylindres, sont emballés avec soin pour garantir une livraison en toute sécurité. Chaque composant est sécurisé dans des matériaux de protection pour éviter tout dommage pendant le transport. Le réseau logistique garantit des expéditions ponctuelles dans le monde entier, soutenir des opérations de maintenance efficaces. Vous trouverez ci-dessous une image illustrant l'emballage standard des pièces de camion FAW., mettant en valeur l’attention portée aux détails dans la manipulation et le stockage.

Cette approche d'emballage minimise le risque de corrosion ou de dommages causés par les chocs., s'assurer que les pièces comme l'ensemble bloc-cylindres FAW arrivent en parfait état. Les clients peuvent compter sur la logistique de FAW pour une qualité et une fiabilité constantes.