This is a comprehensive technical guide to the FAW J6P Activate The Handle system (front enclosure lock) for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck. This deconstruction analyzes the 7 serviceable component types, detailing the remote handle, cable, latches, and hardware that form this critical access and safety mechanism.

The FAW J6P Activate The Handle refers to the complete system used to unlatch the heavy front enclosure panel (grille) of the J6P cab-over-engine design. This system is not a luxury; it is an essential mechanism for daily operations. It allows the driver to remotely release the two main locks securing the front panel, enabling it to pivot open for routine maintenance checks such as inspecting coolant, washer fluid, and oil levels.

This deconstruction will analyze the three core logic groups of the FAW J6P Activate The Handle system: the in-cab driver interface (the handle itself), the mechanical linkage (the cable and clamps), and the latching mechanism (the lock bodies and pins). This entire assembly must be incredibly robust, as it must hold the front panel secure against highway-speed wind forces and extreme off-road vibration, yet release smoothly and reliably on command. A failure in the FAW J6P Activate The Handle system can lead to either a panel detaching at speed or, more commonly, a seized panel that prevents critical engine access, leading to vehicle downtime.

This group of components represents the starting point of the FAW J6P Activate The Handle system. It is the only part of the mechanism the driver interacts with directly.

1. Component: ‘Opening handle assy’ (5302530-A01) – Qty 1

This (Comp 4) is the physical handle located inside the cab, typically in the driver’s footwell or under the dashboard. The Ergonomic Logic requires this component to be durable, easily accessible, and provide enough mechanical leverage for any driver to easily pull and unlatch the heavy-duty locks. It is usually made of high-impact, reinforced ABS plastic.

2. Component: ‘Cross recessed pan head screw’ (Q2140620F6) – Qty 2

This (Comp 5) is the hardware used to mount the ‘Opening handle assy’ (Comp 4) to the cab’s interior panel. While seemingly minor, these fasteners are critical. If they become loose, the entire handle assembly will flex when pulled, rather than transferring all the force to the cable. This gives the FAW J6P Activate The Handle a “spongy” or “broken” feel and may prevent the locks from fully disengaging.

A common failure mode for this part of the FAW J6P Activate The Handle is the plastic handle itself cracking at its pivot point from years of repeated pulling, especially if the cable (Comp 6) becomes stiff or seized.

This group of components forms the mechanical link, transmitting the driver’s pull from the cab-mounted handle to the exterior lock mechanisms. This is the most common failure point in the FAW J6P Activate The Handle system.

1. Component: ‘Cable assy’ (5302550-A01) – Qty 1

This (Comp 6) is the core transmission component. The Tensile Logic is that this cable (a braided steel inner wire inside a low-friction plastic sheath) must transmit a pulling force over a distance, often around several bends. The sheath is anchored at both ends, allowing the inner wire to move freely. This is a critical part of the FAW J6P Activate The Handle.

The cable is highly susceptible to two main failure modes. First is stretching, where the inner wire permanently elongates over time, creating “slack” in the system and preventing the handle from pulling the latches far enough to release. Second, and more common, is seizing. The outer sheath can be chafed, allowing water and grit to enter. This corrodes the inner wire, causing it to bind or seize completely, making the FAW J6P Activate The Handle inoperable.

2. Component: ‘Tie strap clamp II’ (3724012-A01) – Qty 6

This (Comp 7) is arguably the most critical component for the cable’s lifespan. The Chafing Prevention Logic is vital. These six clamps secure the outer sheath of the cable (Comp 6) to the cab body and frame. They prevent the cable from vibrating, kinking, or rubbing against sharp metal edges. A single missing or broken clamp can allow the cable to rub, which will eventually wear a hole in the sheath, leading to the corrosion and failure of the entire FAW J6P Activate The Handle system.

This group of components forms the primary security mechanism of the FAW J6P Activate The Handle. This is the mechanical interface that physically secures the front enclosure panel.

1. Component: ‘Lock body assy – front enclosure’ (5302510-A01) – Qty 2

This (Comp 1) is the main latch mechanism, used in a pair for redundancy and stability. The Rotary Latch Logic is a robust design: when the ‘Lock pin’ (Comp 3) enters, it forces a rotary pawl (cam) to turn and lock behind it. This pawl is held in place by a spring, ensuring the FAW J6P Activate The Handle system cannot be shaken open by vibration. This assembly is mounted to the cab structure.

2. Component: ‘Lock pin assy – front enclosure’ (5302540-A01) – Qty 2

This (Comp 3) is the “striker” or pin. It is mounted on the moving front enclosure panel. This hardened steel pin is designed to align perfectly with the ‘Lock body’ (Comp 1). The Alignment Logic is critical; this pin must guide the heavy panel into the exact closed position. Misalignment of this FAW J6P Front Lock component will cause the panel to be difficult to close or to rattle.

3. Component: ‘Combination bolt’ (CQ1460820F6) – Qty 4

This (Comp 2) is the hardware used to mount the ‘Lock body’ (Comp 1). These are flanged bolts that distribute the clamping load, and they must be installed with thread-locking compound to ensure they do not vibrate loose. A loose lock body is a common source of panel misalignment and failure of the FAW J6P Activate The Handle system.

Maintenance of this part of the FAW J6P Activate The Handle involves periodically cleaning the old grease and debris from the latch (Comp 1) and applying a fresh coat of white lithium grease to ensure the pawl moves freely.

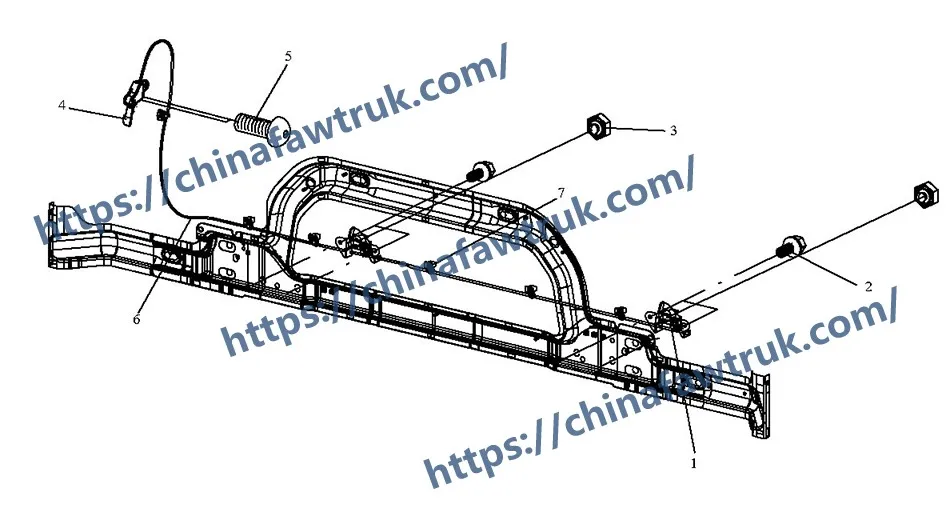

The following table provides the complete, detailed breakdown of all 7 component types in the FAW J6P Activate The Handle (front enclosure lock) assembly for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck. This list is essential for ordering spare parts and performing a complete service of the FAW J6P Activate The Handle.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 5302510-A01 | Lock body assy – front enclosure | 2 |

| 2 | CQ1460820F6 | Combination bolt | 4 |

| 3 | 5302540-A01 | Lock pin assy – front enclosure | 2 |

| 4 | 5302530-A01 | Opening handle assy | 1 |

| 5 | Q2140620F6 | Cross recessed pan head screw | 2 |

| 6 | 5302550-A01 | Cable assy | 1 |

| 7 | 3724012-A01 | Tie strap clamp II | 6 |

The specifications for the FAW J6P Activate The Handle are defined by its function as a remote-actuated, heavy-duty latching system for the cab’s front enclosure panel. A properly functioning FAW J6P Activate The Handle is essential for safety.

| Vehicle Application | FAW Jiefang CA3250P66K2L1T1E 6×4 Dump Truck |

| System Group | FAW J6P Activate The Handle (Front Lock System) |

| Primary Logic | Securing the front enclosure panel (grille) to the cab body |

| Actuation Method | Remote mechanical cable pull |

| Latch Component | ‘Lock body assy’ (5302510-A01) (Qty 2) |

| Striker Component | ‘Lock pin assy’ (5302540-A01) (Qty 2) |

| Release Mechanism | ‘Opening handle assy’ (5302530-A01) & ‘Cable assy’ (5302550-A01) |

| Cable Routing | ‘Tie strap clamp II’ (3724012-A01) (Qty 6) |

| Total Component Types | 7 |

| Associated System | Cab Exterior / Safety Systems. The FAW J6P Activate The Handle is a key safety device. |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.