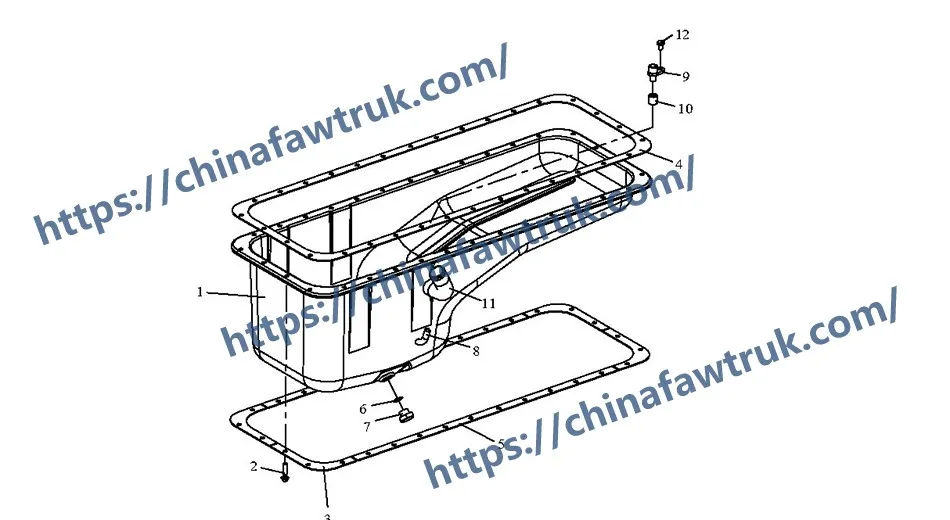

Welcome to this expert deconstruction of the FAW J6P Oil Pan (Main Assy P/N 1009010-70A). This is the core “lubrication reservoir” for the engine on the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck.

This is not a simple “pan”; it is a complex 12-component “Logic Assembly” engineered for three critical, non-negotiable tasks.

The “logic” of this FAW J6P Oil Pan is to: 1) Securely store the engine’s 20L+ oil supply; 2) Control oil “surge” during extreme vehicle movement; and 3) Provide a perfect, leak-proof seal for the engine’s crankcase.

The “Surge Control Logic” is the most critical and advanced feature of this FAW J6P Oil Pan. A heavy-duty dump truck operates on extreme inclines, declines, and off-camber terrain. This environment causes the oil in a simple pan to “slosh” violently.

If the oil pump’s pickup tube becomes uncovered for even a split second, the engine starves of oil, leading to catastrophic bearing failure. This is why the assembly includes four (4) ‘Baffle plates’ (Comp 3) and two (2) ‘Intermediate plates’ (Comp 5).

This internal “maze” logic is designed to trap oil at the pickup tube, guaranteeing 100% oil pressure, which is the most important “logic” in this FAW J6P Oil Pan assembly.

This technical guide is an essential resource for engine technicians, maintenance managers, and parts specialists. We will deconstruct the entire 12-component group into its four primary “logic” systems: the “Reservoir & Baffle Logic,” the “Sealing & Service Logic,” the “Fluid Interface Logic,” and the critical “Clamping Force Logic” for the FAW J6P Oil Pan.

This group forms the main body of the FAW J6P Oil Pan and its most important internal feature: the anti-surge system.

1. Component: ‘Oil pan assy’ (1009010-70A)

This (Comp 1) is the main “Reservoir Logic.” It is a large-volume pan, likely made from stamped steel or cast aluminum, designed to hold the 20L+ of oil required by a heavy-duty diesel engine.

Its “Cooling Logic” is its large surface area, which acts as a “heat sink,” allowing airflow under the truck to cool the engine oil. This is vital for maintaining lubrication viscosity and extending oil life. The FAW J6P Oil Pan is the primary storage unit for the engine’s lifeblood.

2. Components: ‘Baffle plate-oil pan’ (1009024-29D) & ‘Intermediate plate-oil pan’ (1009026-29D)

This is the “Surge Control Logic” and the most critical part of this FAW J6P Oil Pan. The list calls for four (4) ‘Baffle plates’ (Comp 3) and two (2) ‘Intermediate plates’ (Comp 5). This is a complex internal “maze.”

When the truck brakes hard, accelerates, or climbs a steep hill, these plates “corral” the oil. Their “logic” is to prevent the entire mass of oil from sloshing away from the oil pump pickup tube.

An uncovered pickup tube, even for one second, will suck air (“cavitation”), cause a total loss of oil pressure, and destroy the engine’s main bearings. This internal baffling system is a non-negotiable feature for a true heavy-duty FAW J6P Oil Pan.

This group’s “logic” is to provide a leak-proof seal for the FAW J6P Oil Pan and to allow for basic vehicle service.

1. Component: ‘Gasket-oil pan’ (1009031-29D)

This (Comp 4) is the “Perimeter Seal Logic.” This is not a cheap paper or cork gasket. It is a one-piece, “molded elastomer” (high-temperature, oil-resistant rubber) gasket.

Its “logic” is to be “crush-controlled.” It is designed with a specific shape and hardness to be compressed to a perfect, pre-determined thickness by the 32+ pan bolts (Comp 2). This provides a durable, flexible, and perfectly oil-tight seal that can withstand the engine’s vibrations and heat cycles, preventing leaks from the FAW J6P Oil Pan.

2. Components: ‘Hex head oil drain plug’ (1009022-29D) & ‘Seal gasket’ (CQ72320)

This (Comp 7) is the “Service Access Logic.” This plug is the single access point for draining the engine oil. The ‘Seal gasket’ (Comp 6) is its critical partner. This is a “crush washer” logic. It is a single-use washer (often copper or soft aluminum) that is designed to deform when the plug is tightened, creating a perfect metal-on-metal seal. Re-using this gasket is a primary cause of drain plug leaks.

This group’s “logic” is to allow other engine systems to “interface” with the oil supply stored in the FAW J6P Oil Pan.

1. Component: ‘Oil return pipe-oil-gas separator’ (1009043-70A)

This (Comp 8) is the “PCV Return Logic.” The engine’s crankcase ventilation (PCV) system (or ‘oil-gas separator’) removes oil vapor from the “blow-by” gas. This component is the “return pipe” that allows this captured, liquid oil to drain *back* into the FAW J6P Oil Pan, preventing oil loss and reducing emissions.

2. Components: ‘Oil dipstick tube joint assy’ (1009060-70A) & ‘Seal ring-oil dipstick tube’ (1009053-D1)

This (Comp 9) is the “Level Check Logic.” This is the “port” or “joint” that is welded or bolted to the FAW J6P Oil Pan, which holds the dipstick guide tube. Its “logic” is to provide a sealed path for the driver to check the oil level. The ‘Seal ring’ (Comp 10) is the O-ring or gasket that provides the leak-proof seal for this tube.

3. Component: ‘Joint’ (1009081-600-070A)

This (Comp 11) is the “Auxiliary Port Logic.” This is an additional fitting on the FAW J6P Oil Pan. Its “logic” is typically to serve as a “return” or “drain” port, most commonly for the turbocharger. The turbo is lubricated by high-pressure oil, and this “joint” is the port where that oil drains back into the pan.

This final group’s “logic” is to provide a secure, vibration-proof, and evenly-distributed clamping force to seal the FAW J6P Oil Pan to the engine block.

Components: ‘Hexagon flange bolt’ (Q1840820) & (Q1860816)

This is the “Clamping Logic.” The list calls for thirty-two (32) ‘Hexagon flange bolts’ (Comp 2) plus one (1) ‘large series’ bolt (Comp 12).

This massive number of bolts (33+ total) is not for “strength”—it’s for “evenness.” The “logic” is to distribute the clamping force perfectly across the entire ‘Gasket-oil pan’ (Comp 4). This even pressure is what prevents the gasket from failing and the pan flange from warping.

The “Flange Logic” of these bolts is also important. The “flange” is a built-in washer. This is superior because it spreads the load from the bolt head over a wider area of the FAW J6P Oil Pan‘s rail, preventing the bolts from “cracking” the pan flange or vibrating loose.

A properly torqued set of these fasteners is essential to a leak-free FAW J6P Oil Pan.

The following table provides the complete, detailed breakdown of all 12 component types identified in this FAW J6P Oil Pan assembly for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 1009010-70A (1009010B600-070A) | Oil pan assy | 1 |

| 2 | Q1840820 | Hexagon flange bolt | 32 |

| 3 | 1009024-29D | Baffle plate-oil pan | 4 |

| 4 | 1009031-29D (1009031-29DZ) | Gasket-oil pan (Fully interchangeable) | 1 |

| 5 | 1009026-29D | Intermediate plate-oil pan | 2 |

| 6 | CQ72320 (Q72320) | Seal gasket | 1 |

| 7 | 1009022-29D (1009022A29D) | Hex head oil drain plug | 1 |

| 8 | 1009043-70A (1009043-600-070A) | Oil return pipe-oil-gas separator | 1 |

| 9 | 1009060-70A (1009060-600-070A) | Oil dipstick tube joint assy | 1 |

| 10 | 1009053-D1 (1009053A29D) | Seal ring-oil dipstick tube | 1 |

| 11 | 1009081-600-070A (1009081-600-070A) | Joint | 1 |

| 12 | Q1860816 | Hexagon flange bolt-large series | 1 |

The specifications for the FAW J6P Oil Pan assembly are defined by its function as the primary reservoir and surge-control system for the engine’s lubrication.

| Vehicle Application | FAW Jiefang CA3250P66K2L1T1E 6×4 Dump Truck |

| System Group | FAW J6P Oil Pan Assembly |

| Main Pan Assembly P/N | 1009010-70A |

| Primary Logic | Oil Storage, Oil Cooling, Oil Surge Control |

| Baffle System | ‘Baffle plate’ (1009024-29D) – Qty 4 |

| Intermediate Baffle System | ‘Intermediate plate’ (1009026-29D) – Qty 2 |

| Sealing System | ‘Gasket-oil pan’ (1009031-29D) – Molded Elastomer |

| Fastener System | ‘Hexagon flange bolt’ (Q1840820) – Qty 32 |

| Service Port | ‘Hex head oil drain plug’ (1009022-29D) |

| Interface 1 (PCV) | ‘Oil return pipe-oil-gas separator’ (1009043-70A) |

| Interface 2 (Level Check) | ‘Oil dipstick tube joint assy’ (1009060-70A) |

| Interface 3 (Auxiliary) | ‘Joint’ (1009081-600-070A) – (e.g., Turbo Drain) |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.