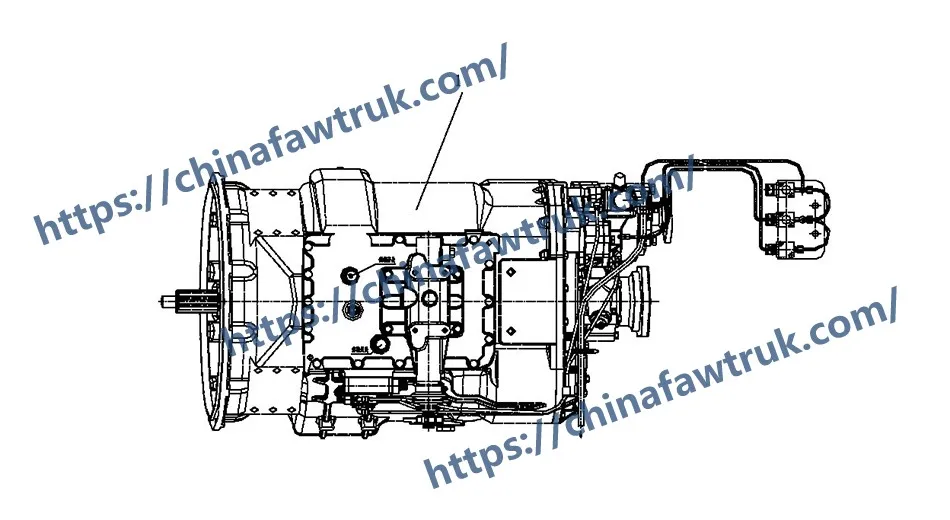

Welcome to this core analysis of the FAW J6P Gearbox, model CA10TA160M, as used in the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck. This is the central component of the drivetrain, responsible for multiplying engine torque to move heavy loads. This guide is for technicians, deconstructing the main assembly for a complete operational understanding of the FAW J6P Gearbox.

The FAW J6P Gearbox is a heavy-duty, multi-speed manual transmission. Its design, featuring a flange-connected PTO, is critical for the dump truck’s dual-role: providing massive torque for off-road traction and also powering the hydraulic system for the dump body. Understanding its internal logic is key to vehicle uptime and proper service.

This section covers the “front” of the FAW J6P Gearbox, the area responsible for connecting to the engine’s clutch and transferring 100% of the engine’s power into the gear sets. Its logic is about alignment, sealing, and input.

1. Component: Input Shaft (Main Drive Gear)

The Input Shaft Logic is its dual function. First, the externally splined shaft projects forward to engage with the ‘Clutch driven plate assy’. This is how it receives power from the FAW J6P Clutch. Second, the “gear” portion of this shaft resides *inside* the FAW J6P Gearbox, acting as the primary drive gear for the countershaft.

This shaft must be perfectly centered and supported by a high-load input bearing. This bearing, and its associated seal, are critical service items. A seal failure here will leak transmission oil directly into the dry bellhousing, contaminating and destroying the FAW J6P Clutch.

2. Component: Bellhousing & Bearing Retainer

The Alignment Logic is the bellhousing’s main purpose. This cast-iron or aluminum “bell” bolts to the back of the engine. It uses precision dowel pins to ensure the FAW J6P Gearbox input shaft is *perfectly* concentric with the engine’s crankshaft. Any misalignment would cause catastrophic vibration and bearing failure.

The Mounting Logic of the bearing retainer is also key. This retainer bolts to the front of the FAW J6P Gearbox, contains the input oil seal, and often provides the “guide tube” or “quill” that the clutch’s ‘Release bearing’ slides on. It is the structural “front door” of the transmission.

This is the “front box” or main case of the FAW J6P Gearbox. The model CA10TA160M signifies a 10-speed transmission. In a heavy-duty truck, this is almost always a “5×2” design: a 5-speed main box with a 2-speed auxiliary section. This core logic covers the main 5 speeds.

1. Component: Countershaft (or Layshaft)

The Countershaft Logic is “constant drive.” The countershaft is in constant mesh with the input shaft gear. Any time the FAW J6P Clutch is engaged and the engine is spinning, the countershaft is spinning. All the main “drive” gears are forged as a single piece onto this shaft.

In a heavy-duty FAW J6P Gearbox, there are often *two* countershafts (a “twin countershaft” design). This splits the engine’s torque, reducing the load on each individual gear tooth, which dramatically increases torque capacity and service life.

2. Component: Mainshaft & Gear Sets

The Mainshaft Logic is “selective engagement.” The mainshaft (or “output shaft” of this section) holds all the “driven” gears (e.g., 1st, 2nd, 3rd, 4th, 5th/Reverse). These gears are *not* fixed to the shaft. They are in constant mesh with the countershaft gears and spin freely on the mainshaft on needle bearings.

3. Component: Synchronizer Assemblies (Synchros)

The Synchronizer Logic is what makes the FAW J6P Gearbox “shiftable.” This is the “magic” of a modern manual transmission. A synchronizer is a splined “dog clutch” that sits on the mainshaft between two free-spinning gears.

When the driver moves the shift lever, they are moving a “shift fork,” which slides the synchronizer assembly. The Friction Logic of the synchro’s “blocker ring” (made of brass or carbon) first acts as a small clutch, physically speeding up or slowing down the free-spinning gear to match the *exact* speed of the mainshaft.

Once the speeds are matched (in a fraction of a second), the “dog teeth” of the synchro can slide and lock onto the gear. This action locks that specific gear to the mainshaft, and power flows. This “speed matching” is what prevents the grinding noise associated with old “crash box” transmissions. This is a critical system in the FAW J6P Gearbox.

This is the “back box” or auxiliary section of the FAW J6P Gearbox. Its logic is to act as a “multiplier” for the 5-speed main box, doubling the available gear ratios and giving the driver 10 speeds.

1. Component: Range Gear Set (Hi/Lo)

The Range Logic is typically a 2-speed planetary or simple gear set. It is mounted *after* the 5-speed mainshaft. This means it takes the output of the main box (e.g., “3rd gear”) and can route it through either a “Low” (direct drive or slight reduction) or “High” (overdrive) gear.

The Pneumatic Logic is how it is shifted. The driver does not use the main shift lever for this. They use a small switch on the gear knob. This switch controls an air-powered “range slave” or “range cylinder” mounted on the FAW J6P Gearbox. This cylinder, using air from the truck’s main system, shifts the range section between Hi and Lo.

This 5×2 setup is what gives the FAW J6P Gearbox its versatility. The “Lo” range (gears 1-5) provides the massive torque multiplication needed for starting on a steep hill or in deep mud. The driver then “range shifts” into “Hi” range and uses the same 5-gear pattern again (now gears 6-10) for highway cruising.

2. Component: Output Shaft & Flange

The Output Logic is the final stage. The output shaft of the auxiliary section is the final component. It is a heavy-duty, hardened shaft supported by a large output bearing and sealed by a main output seal. It terminates in a large “yoke” or “flange” (as noted in the PTO description) that connects to the truck’s main driveshaft.

This is a critical, specified feature of this FAW J6P Gearbox model (法兰联接取力器 – Flange-connected Power Take-Off). This system’s logic is to “take off” or “borrow” the engine’s power from the transmission to run auxiliary equipment.

1. Component: PTO Drive Gear

The Drive Logic starts with the PTO drive gear, which is typically on the main countershaft. This means the PTO gear is spinning *anytime* the FAW J6P Clutch is engaged.

2. Component: Power Take-Off (PTO) Unit

The PTO Unit is a separate, small, cast-iron gearbox that bolts to an “aperture” or “window” on the side of the main FAW J6P Gearbox case. It has its own sliding gear that is engaged by the driver (usually via an air-shift switch in the cab).

The Actuation Logic is key: the driver puts the main FAW J6P Gearbox in neutral (so the truck doesn’t move), engages the FAW J6P Clutch, and then flips the PTO switch. The air-shifter slides the PTO’s idler gear into mesh with the spinning countershaft gear. The driver then releases the clutch.

3. Component: Flange Connection

The Output Logic of the PTO is its own output shaft. As specified, this is a Flange Connection. This is a robust, universal joint flange that is perfect for connecting a short driveshaft.

On this CA3250P66K2L1T1E dump truck, this PTO flange is absolutely essential. It runs the driveshaft that powers the truck’s main hydraulic pump. This hydraulic pump is what provides the high-pressure fluid to the hydraulic cylinder that “dumps” the truck’s body. Without this PTO, the entire “dump” function is inoperable. This feature is a core part of the FAW J6P Gearbox system’s identity.

The following table lists the complete main assembly for the FAW J6P Gearbox, model CA10TA160M, as specified for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 1700945D50V | CA10TA160M Gearbox (Flange-connected Power Take-Off) | 1 |

The specifications for the FAW J6P Gearbox assembly are defined by its heavy-duty, multi-speed design, and its integrated support for auxiliary power systems.

| Vehicle Application | FAW Jiefang CA3250P66K2L1T1E 6×4 Dump Truck |

| System Group | FAW J6P Gearbox Assembly |

| Assembly Part No. | 1700945D50V |

| Model | CA10TA160M |

| Primary Logic | Engine Torque Multiplication |

| Speeds | 10-Speed (Implied, 5×2 Range) |

| Gearing Logic | Synchronized Main Box, Air-Shifted Range Box |

| Secondary Logic | Power Take-Off (PTO) Drive |

| PTO Feature | Flange-connected Power Take-Off |

| PTO Application | Powering Hydraulic Pump for Dump Body |

| Associated Systems | FAW J6P Clutch, Driveline, Hydraulic System |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.