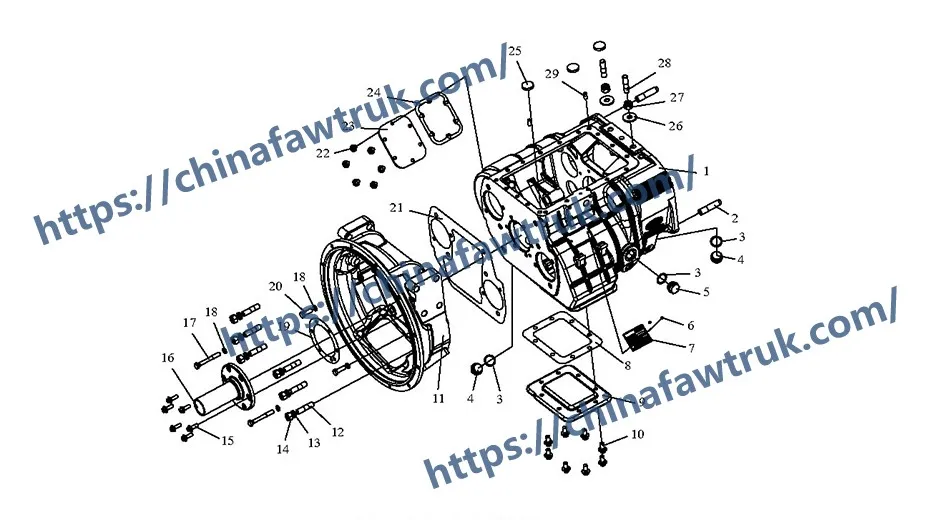

Welcome to this expert analysis of the FAW J6P Gearbox Housing, the foundational structure for the CA10TA160M transmission in the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck. This guide is for technicians, breaking down the 29 components that comprise the complete FAW J6P Gearbox Housing and clutch housing assembly, from the main case to the smallest gasket.

The FAW J6P Gearbox Housing is not just a “box”; it is a high-precision component responsible for perfect shaft alignment, oil sealing, and heat dissipation. Its structural integrity is the single most important factor for a long transmission service life. This guide will deconstruct this critical assembly into its functional subsystems.

This group represents the core “chassis” of the entire transmission. All other components, internal and external, mount to this one part. The FAW J6P Gearbox Housing is the literal foundation.

1. Component: ‘Gearbox body’ (1701031-A7G)

This (Comp 1) is the main case, the ‘Gearbox body’. This is the largest and most complex component, typically cast from high-strength iron or aluminum. Its logic is threefold: alignment, sealing, and heat dissipation.

The Alignment Logic is its most critical function. This main case has precisely bored holes for the input shaft, mainshaft, and countershaft(s) bearings. These bores must be perfectly parallel. Any warping or damage to the FAW J6P Gearbox Housing will cause shaft misalignment, leading to rapid gear and bearing failure.

The Sealing Logic is its obvious function. It acts as a large “sump” or “oil bath” for the entire gear set. It is designed with multiple machined faces for gaskets (like Comp 3, 8, 21, 24) to create a leak-proof enclosure.

The Heat Dissipation Logic is also vital. The entire FAW J6P Gearbox Housing acts as a giant heat sink. The hot transmission oil transfers its heat to the case, and the external fins (if present) and large surface area dissipate this heat to the surrounding air.

This component is the “adapter” that connects the FAW J6P Gearbox Housing to the engine. It is commonly known as the “bellhousing” and is a critical alignment component.

1. Component: ‘Clutch outer housing assy’ (1601010-A1K / 1601010D76A)

This (Comp 11) is the ‘Clutch Outer Housing Assembly’. This large, bell-shaped component bolts to the front of the ‘Gearbox body’ (Comp 1) and creates the “dry” enclosure for the clutch assembly. The two part numbers indicate an option, likely based on the simultaneous selection of 1701112-A7G, as noted.

The Engine Interface Logic is its primary role. This housing bolts to the back of the engine block. Its “alignment” is ensured by ‘Dowel pins’ (Comp 2, `定位销-副箱売` – Positioning pin-auxiliary box housing), which precisely locate it relative to the engine’s crankshaft. This ensures the FAW J6P Gearbox Housing input shaft is perfectly centered.

The Mechanism Mount Logic is its secondary role. This housing provides the mounting points for the clutch release fork and shaft (seen in the ‘Clutch Control Mechanism’ breakdown), allowing the external hydraulic force to be transferred inside. This part of the FAW J6P Gearbox Housing is essential for clutch operation.

This group includes all the components designed to seal the various “ports” or “windows” on the main FAW J6P Gearbox Housing. These ports allow for service, inspection, and the addition of auxiliary equipment.

1. The “PTO Port” Group (Comp 8, 9, 23, 24)

This group includes: ‘Gasket-PTO bottom port’ (Comp 8), ‘Cover-PTO bottom port’ (Comp 9), ‘Cover-PTO side port’ (Comp 23), and ‘Gasket-PTO side port’ (Comp 24).

The Modularity Logic is the purpose of these components. The FAW J6P Gearbox Housing is cast with standardized, 6-bolt or 8-bolt “windows” (PTO ports) on its sides and/or bottom. This allows for the easy installation of a Power Take-Off (PTO) unit to run hydraulic pumps or other equipment.

Since this truck uses a flange-connected PTO (as seen in the main gearbox assembly), these *other* ports are not needed. Therefore, simple ‘Covers’ and ‘Gaskets’ are used to securely seal them, preventing oil leaks from the FAW J6P Gearbox Housing.

2. The “Service Port” Group (Comp 4, 25)

This group includes: ‘Oil drain plug assy’ (Comp 4) and ‘Magnet’ (Comp 25). The ‘Oil drain plug’ is the primary service point for draining the old gear oil from the FAW J6P Gearbox Housing.

The Magnetic Logic is the function of the ‘Magnet’ (Comp 25). This magnet is either part of the ‘Oil drain plug assy’ or sits just inside it. Its critical job is to attract and capture any microscopic ferrous metal particles (from normal gear wear) circulating in the oil. Inspecting this magnet during an oil change is the best way to diagnose the internal health of the FAW J6P Gearbox Housing.

This group of components is responsible for holding the main shaft bearings in place and, most importantly, sealing the rotating shafts as they exit the FAW J6P Gearbox Housing.

1. Components: ‘Bearing – first shaft’ (1701141-A7G) & ‘Cover – first shaft bearing’ (1701142-A7G)

This (Comp 16 & 19) is the complete “input shaft” bearing and cover assembly. The ‘Bearing’ (Comp 16) is the main bearing that supports the input shaft, pressed into the front of the FAW J6P Gearbox Housing.

The Bearing Retainer Logic is the function of the ‘Cover’ (Comp 19). This cover bolts to the front of the FAW J6P Gearbox Housing (using bolts Comp 17 and 20). It has two jobs: 1) It acts as a “retainer,” physically holding the outer race of the bearing (Comp 16) and preventing it from moving. 2) It contains the all-important input shaft oil seal.

The Input Seal Logic is the most critical sealing function in the entire system. This seal (housed in Comp 19) is what keeps the high-temperature gear oil *inside* the FAW J6P Gearbox Housing and keeps the “dry” clutch housing free of oil. A failure of this one seal will immediately cause the clutch to slip and fail.

This final group includes all the specialized bolts, nuts, and gaskets used to assemble the FAW J6P Gearbox Housing. Their logic is to provide precise alignment, secure clamping force, and leak-proof static sealing.

1. The “Alignment” Group (Comp 2, 17, 20, 29)

This group includes ‘Dowel pin’ (Comp 2), ‘Hexagon head bolt with guide neck’ (Comp 17, 20), and ‘Cylindrical pin’ (Comp 29). The Precise Fit Logic is key. Dowel pins align the main housing (Comp 1) to the clutch housing (Comp 11). The “guide neck” bolts (Comp 17, 20) are used to perfectly align the ‘First shaft bearing cover’ (Comp 19) before the threads engage. This precision is non-negotiable for the FAW J6P Gearbox Housing.

2. The “Clamping” Group (Comp 10, 12, 14, 15, 22, 27, 28)

This is the main hardware for bolting the housings together. It includes ‘Hex flange bolts’ (Comp 10, 15, 22), ‘Double head bolts’ (Comp 12, 28), ‘Hex nuts’ (Comp 14), and ‘Type I all-metal hexagon flange locknuts’ (Comp 27).

The High-Tensile Logic of these fasteners ensures the entire FAW J6P Gearbox Housing can withstand the immense torque and twisting forces from the engine and drivetrain. The “locknuts” (Comp 27) are special, one-time-use nuts that are deformed to create a mechanical lock, preventing them from ever backing off.

3. The “Sealing” Group (Comp 3, 5, 8, 13, 18, 21, 24, 26)

This group includes all the static seals: ‘Gasket’ (Comp 3, 21), ‘Grommet’ (Comp 5), ‘Gasket-PTO…’ (Comp 8, 24), ‘Spring washer’ (Comp 13, 18), and ‘Large washer’ (Comp 26). The ‘Gaskets’ provide the primary paper/cork/metal seal between flat, machined surfaces of the FAW J6P Gearbox Housing. The ‘Spring washers’ provide the anti-vibration logic, ensuring the bolts maintain clamping force.

The following table provides the complete, detailed breakdown of all 29 component types in the FAW J6P Gearbox Housing and clutch housing assembly for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 1701031-A7G | Gearbox body | 1 |

| 2 | 1701052-A7G | Dowel pin – auxiliary box housing | 2 |

| 3 | 1701033-11 | Gasket | 3 |

| 4 | 1701030-A4H | Oil drain plug assy | 2 |

| 5 | 1701031-11 | Grommet | 1 |

| 6 | Q214046 | Cross recessed head screw | 2 |

| 7 | 1701046-A7G | Gearbox nameplate | 1 |

| 8 | 1701037-A7G | Gasket – PTO bottom port | 1 |

| 9 | 1701036-A7G | Cover – PTO bottom port | 1 |

| 10 | Q1841225S | Hexagon flange bolt | 8 |

| 11 | 1601010-A1K 1601010D76A | Clutch outer housing assy (Select simultaneously with 1701112-A7G) | 1 |

| 12 | 1701026-A7G | Double head bolt | 6 |

| 13 | Q40316 | Spring washer | 6 |

| 14 | CQ34116T | Hexagon nut | 6 |

| 15 | Q1841030S | Hexagon flange bolt | 6 |

| 16 | 1701141-A7G | Bearing – first shaft | 1 |

| 17 | CQ1601290TS | Hexagon head bolt with guide neck | 2 |

| 18 | Q40312 | Spring washer | 4 |

| 19 | 1701142-A7G | Cover – first shaft bearing | 1 |

| 20 | CQ1601235TS | Hexagon head bolt with guide neck | 2 |

| 21 | 1701022-A7G | Gasket | 1 |

| 22 | Q1841020S | Hexagon flange bolt | 6 |

| 23 | 1701043-A7G | Cover – PTO side port | 1 |

| 24 | 1701044-A7G | Gasket – PTO side port | 1 |

| 25 | 1701033-A7G | Magnet | 3 |

| 26 | Q40216 | Large washer | 2 |

| 27 | Q32916 | Type I all-metal hexagon flange locknut | 2 |

| 28 | CQ1211645S | Double head bolt | 2 |

| 29 | Q5221226 | Cylindrical pin | 2 |

The specifications for the FAW J6P Gearbox Housing are defined by its role as the primary structural and alignment component for the entire transmission assembly.

| Vehicle Application | FAW Jiefang CA3250P66K2L1T1E 6×4 Dump Truck |

| System Group | FAW J6P Gearbox Housing & Clutch Housing |

| Primary Logic | Structural Support & Shaft Alignment |

| Secondary Logic | Oil Containment, Heat Dissipation, PTO Port Sealing |

| Core Component | ‘Gearbox body’ (1701031-A7G) |

| Interface Component | ‘Clutch outer housing assy’ (1601010-A1K / 1601010D76A) |

| Input Shaft Sealing | ‘Cover – first shaft bearing’ (1701142-A7G) |

| Service Points | ‘Oil drain plug assy’ (1701030-A4H) |

| Debris Capture | ‘Magnet’ (1701033-A7G) – Qty 3 |

| PTO Port Covers | ‘Cover-PTO bottom port’ (1701036-A7G), ‘Cover-PTO side port’ (1701043-A7G) |

| Total Component Types | 29 |

| Associated System | CA10TA160M FAW J6P Gearbox Housing & Internal Gearing |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.