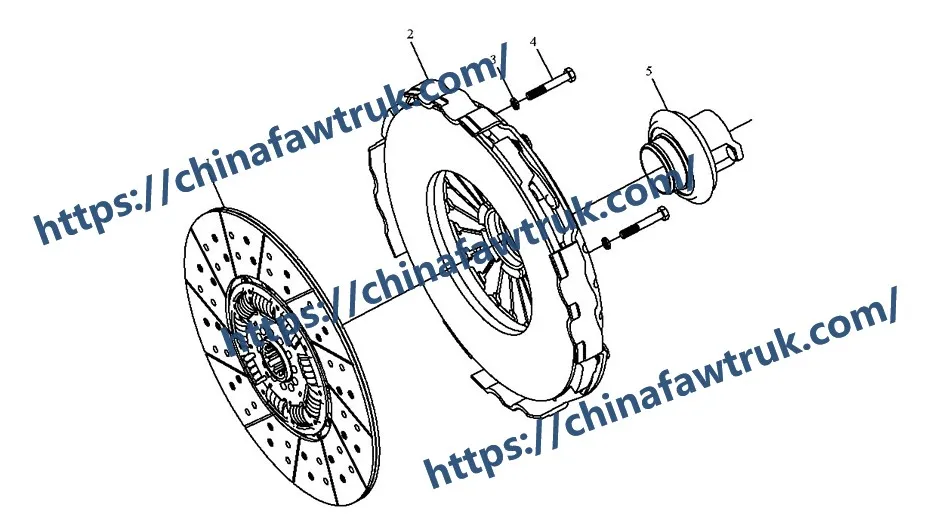

Welcome to this essential technical breakdown of the FAW J6P Clutch assembly, the core component for transmitting engine power in the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck. This guide is built for professional technicians and parts specialists, deconstructing the 5 critical components that make up the entire FAW J6P Clutch system, from the pressure plate to the release bearing.

The FAW J6P Clutch is the critical “switch” that engages and disengages the engine from the transmission. In a high-torque, stop-and-go dump truck environment, its reliability is paramount for ensuring smooth starts, protecting the transmission from shock, and providing a long service life. This deconstruction is key to understanding its operation and maintenance.

This component is the literal “center” of the FAW J6P Clutch. It is the only part that connects to the transmission, and it is the primary “wear” item in the entire system.

1. Component: ‘Clutch driven plate assy’ (1601210-1909-C00)

This (Comp 1) is the ‘Clutch Driven Plate Assembly’, often just called the “clutch disc.” Its logic is twofold: friction and damping.

The Friction Logic is its primary purpose. The disc is lined on both sides with a high-coefficient friction material (such as an organic-ceramic mix). This material is designed to be “grabbed” with immense force, locking it against the engine’s flywheel and the ‘Clutch cover assy’ (Comp 2). This high-grip, high-temperature material is what allows the FAW J6P Clutch to transfer thousands of newton-meters of torque without slipping.

The Splined Hub Logic is how it transfers power. The center of the disc is a hardened steel hub with internal splines. This hub slides directly onto the *input shaft* of the truck’s transmission. When the disc is “grabbed” by the pressure plate, it spins, and these splines turn the transmission input shaft, moving the truck.

The Torsional Damping Logic is its most critical, and often hidden, function. The central hub is not rigidly fixed to the outer friction plate. It is connected via a series of large, heavy-duty coil springs. These springs are “torsional dampers.”

A heavy-duty diesel engine does not spin smoothly; it “fires” in violent pulses. These springs in the FAW J6P Clutch disc act like a “shock absorber,” compressing and expanding by a few degrees with every engine pulse. This “damping” action smooths out the power delivery, protecting the transmission’s gears, the driveshafts, and the differentials from this shock. This feature is essential for drivetrain longevity in the FAW J6P Clutch system.

This component is the “muscle” of the FAW J6P Clutch. It bolts to the engine and provides the massive, constant force required to lock the clutch disc in place.

1. Component: ‘Clutch cover assy’ (1601310-1908-C00)

This (Comp 2) is the ‘Clutch Cover Assembly’, universally known as the “pressure plate.” This entire assembly bolts directly to the engine’s *flywheel* (using Comp 4) and spins *with the engine* at all times.

The Diaphragm Spring Logic is its core technology. Inside the heavy steel cover is a single, massive, cone-shaped spring called a “diaphragm spring.” In its natural, resting state, this spring exerts *thousands of pounds* of clamping force.

This Clamping Logic is what makes the FAW J6P Clutch work. This immense spring force pushes a heavy, cast-iron pressure ring forward. This action “squeezes” the ‘Driven plate’ (Comp 1) against the flat surface of the engine’s flywheel. This “sandwich” creates a solid, locked connection, allowing the engine’s rotation to be transferred to the ‘Driven plate’ and thus to the transmission.

The Release Logic is how the system disengages. When the driver presses the clutch pedal, the ‘Release bearing’ (Comp 5) is pushed forward by the ‘Clutch Control Mechanism’. This bearing presses on the *center* fingers of the diaphragm spring.

This “over-center” action acts like a lever, causing the *outer* edge of the spring to pull *backwards*, retracting the pressure ring. This retraction *releases* the clamping force on the ‘Driven plate’, allowing it to spin freely and disconnecting the engine from the transmission. This is the “disengaged” state of the FAW J6P Clutch.

This component is the “messenger” or “actuator” in the FAW J6P Clutch system. It is the part that physically bridges the gap between the stationary clutch fork and the spinning pressure plate.

1. Component: ‘Clutch release bearing assy (long bearing)’ (1601430BA0H)

This (Comp 5) is the ‘Clutch Release Bearing Assembly’. This component is held by the ‘Release fork’ (from the ‘Clutch Control Mechanism’) and slides back and forth on a sleeve.

The Rotational Interface Logic is its sole purpose. The ‘Clutch cover assy’ (Comp 2) is spinning at engine RPM (e.g., 2000 RPM). The clutch fork is stationary. This bearing is the interface. One side of it (the “cup”) is static and held by the fork. The other side (the “face”) is a high-speed bearing designed to make contact with the spinning diaphragm fingers and spin *with* them to prevent catastrophic friction and heat.

The Push Logic is how it actuates. This is a “push-type” bearing. When the driver presses the pedal, the fork pushes this bearing *forward* (towards the engine). This forward movement is what presses on the diaphragm fingers to disengage the FAW J6P Clutch.

The Specification Logic is critical: ‘(long bearing)’. This “long bearing” designation is a precise-fit item. It means the bearing is a specific height to match the geometry of the ‘Clutch Control Mechanism’ and the FAW J6P Clutch cover. Using a “short bearing” in its place would result in a pedal that goes to the floor without disengaging the clutch. This part is replaced every time the FAW J6P Clutch is serviced.

This final group is the hardware that holds the entire FAW J6P Clutch assembly together. Its failure means a total and catastrophic loss of drive.

1. Components: ‘Hexagon head bolt with guide neck’ (CQ1501070T, Qty 12) & ‘Spring washer’ (Q40310, Qty 12)

These (Comp 3 & 4) are the 12 critical fasteners that bolt the ‘Clutch cover assy’ (Comp 2) directly to the engine’s flywheel, “sandwiching” the ‘Driven plate’ (Comp 1) inside.

The High-Tensile Logic is paramount. These are not standard bolts. They are high-tensile (e.g., Grade 10.9 or 12.9) fasteners engineered to withstand the full rotational torque of the engine *and* the immense, constant clamping force from the diaphragm spring.

The Guide Neck Logic is a precision feature. The ‘guide neck’ on the bolt (Comp 4) is a non-threaded shoulder section. Its logic is to fit snugly into the mounting holes of the FAW J6P Clutch cover *before* the threads engage in the flywheel. This provides perfect alignment and concentricity, which is essential for preventing vibration.

The Anti-Vibration Logic is the job of the ‘Spring washers’ (Comp 3). A heavy-duty diesel engine produces intense, low-frequency vibrations that can easily loosen bolts. These high-tension spring washers provide constant pre-load, pushing against the bolt heads and preventing them from backing out. This ensures the FAW J6P Clutch remains securely mounted.

The following table provides the complete, detailed breakdown of all 5 component types in the FAW J6P Clutch assembly for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck.

| Part No. | Part Name | Quantity |

|---|---|---|

| 1601210-1909-C00 | Clutch driven plate assy | 1 |

| 1601310-1908-C00 | Clutch cover assy | 1 |

| Q40310 | Spring washer | 12 |

| CQ1501070T | Hexagon head bolt with guide neck | 12 |

| 1601430BA0H | Clutch release bearing assy (long bearing) | 1 |

The specifications for the FAW J6P Clutch assembly are defined by its function as the primary torque transfer component, engineered for high-load capacity and long-term durability in a dump truck application.

| Vehicle Application | FAW Jiefang CA3250P66K2L1T1E 6×4 Dump Truck |

| System Group | FAW J6P Clutch Assembly |

| Primary Logic | Engine Torque Transfer (Engagement/Disengagement) |

| Core Component (Friction) | ‘Clutch driven plate assy’ (1601210-1909-C00) |

| Driven Plate Feature | Torsional Damper Springs (Shock Absorption) |

| Core Component (Force) | ‘Clutch cover assy’ (1601310-1908-C00) |

| Cover / Pressure Plate Type | Diaphragm Spring (High Clamping Force) |

| Core Component (Actuation) | ‘Clutch release bearing assy’ (1601430BA0H) |

| Bearing Type | Push-type, (Long bearing) Specification |

| Mounting Hardware | 12x ‘Hexagon head bolt with guide neck’ (CQ1501070T) |

| Vibration Hardware | 12x ‘Spring washer’ (Q40310) |

| Associated System | FAW J6P Clutch Control Mechanism |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.