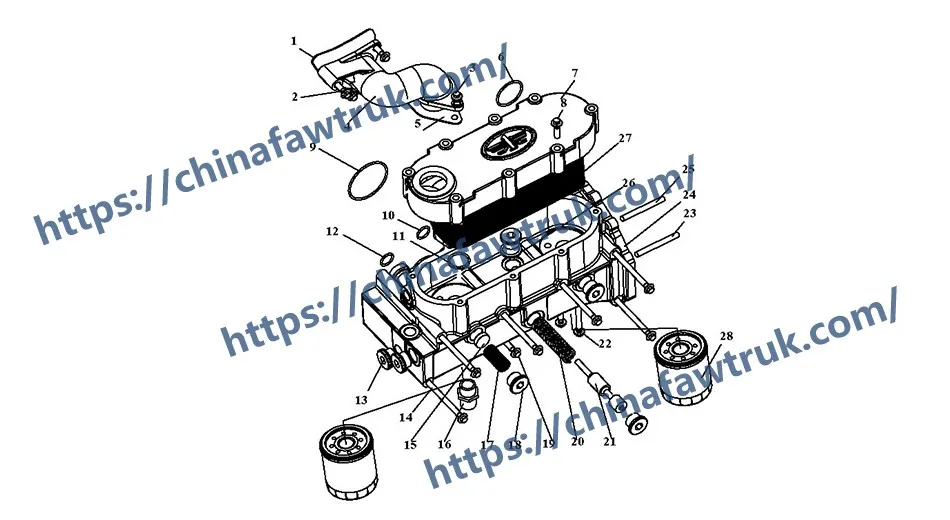

Welcome to this expert deconstruction of the FAW J6P Engine Oil Cooler (Main Assy P/N 1013010-36D). This is the complete “Lubrication & Thermal Management Module” for the engine on the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck.

This is not just a simple radiator; it is a highly complex “Logic Assembly” of 28 component types, integrating the oil cooler, the oil filter mounts, and multiple pressure-control valves.

The “logic” of this FAW J6P Engine Oil Cooler is to be the “life-support” system for the engine’s oil, performing three tasks: cooling, filtering, and regulating pressure.

The “Thermal Logic” of this FAW J6P Engine Oil Cooler is its most obvious function. Engine oil does more than lubricate; it actively *cools* the pistons and turbocharger. This module is a “liquid-to-liquid” heat exchanger. It runs hot engine oil through a “stack” of plates, while running cold engine coolant through alternating plates. This massive surface area efficiently *transfers heat from the oil to the coolant*, where the truck’s main radiator can dissipate it. This “logic” is the only thing that prevents the oil from overheating, “coking,” and destroying the turbo.

This technical guide is an essential resource for engine rebuilders, machine shop technicians, and fleet parts managers. We will deconstruct the entire 28-component group into its four primary “logic” systems: the “Heat Exchange Logic” (the cooler core and body), the “Filtration Interface Logic” (the filter mounts), the critical “Fluid Regulation Logic” (the bypass, safety, and pressure valves), and the “Sealing & Fastener Logic” that connects the entire FAW J6P Engine Oil Cooler module to the engine.

This group forms the core purpose of the FAW J6P Engine Oil Cooler: to remove heat from the lubrication circuit.

1. Components: ‘Oil cooler assy’ (1013010-36D) & ‘Oil cooler body’ (1013011-36D)

This is the “Plate-Stack Logic.” The ‘Oil cooler assy’ (Comp 27) is the complete “core”—a sealed “stack” of numerous thin aluminum plates. Its “logic” is to create a massive surface area in a small space. Hot oil flows through one set of plates, while cool engine coolant flows through an alternating set. This is far more efficient than an old “tube-and-fin” cooler. The ‘Oil cooler body’ (Comp 24) is the cast aluminum “housing” that this core stack is inserted into. It provides the main

structure, the mounting points, and all the fluid ports for the FAW J6P Engine Oil Cooler.

2. Component: ‘Oil cooler cover plate’ (1013021-29D)

This (Comp 7) is the “Access & Sealing Logic.” This plate is what holds the ‘Oil cooler assy’ (the core) inside the ‘Body’ (Comp 24). It is sealed with a large O-ring (Comp 9) and is held on by multiple bolts (Comp 8). This “logic” makes the FAW J6P Engine Oil Cooler “serviceable”—a technician can remove this cover to replace just the cooler core if it becomes clogged or leaks, without replacing the entire expensive housing.

This group’s “logic” is to integrate the engine’s oil filters directly into the FAW J6P Engine Oil Cooler module, saving space and simplifying plumbing.

1. Component: ‘Oil filter assy’ (1012010-36D)

This (Comp 28) is the main “Filtration Logic.” The list calls for two (2) of these “spin-on” filters. The “logic” of the FAW J6P Engine Oil Cooler body is to act as the “docking station” for these filters. Clean oil from the pump flows *into* these filters, passes through the media, and *then* flows to the cooler and the engine.

2. Component: ‘Nut-oil filter connector’ (1013022-29D)

This (Comp 16) is the “Mounting Logic.” The list calls for two (2) of these. These are the hollow, threaded “nipples” or “connectors” that are screwed into the cooler body (Comp 24). The ‘Oil filter assy’ (Comp 28) spins onto these connectors. Their “hollow logic” is what allows the oil to flow in and out of the filter. They are held in place by ‘Hex flange nuts’ (Comp 11).

This is the “brain” of the FAW J6P Engine Oil Cooler. It contains three separate valves to manage oil flow in all conditions.

1. The “Cold Start” Logic: ‘Bypass valve – oil cooler’ (1013027-29D)

This (Comp 15) is the “Cold Oil Logic.” On a -20°C startup, oil is thick as honey. Forcing it through the tiny plates of the FAW J6P Engine Oil Cooler would create massive back-pressure and starve the engine. This “thermal-bypass” valve “logic” senses this high pressure (or temperature) and *opens*, allowing the cold, thick oil to *go around* (bypass) the cooler core and flow directly to the engine bearings. As the oil warms up, this valve closes, forcing oil back

through the cooler.

2. The “Pressure Regulation” Logic: ‘Pressure regulating valve core’ (1013023-29D) & ‘Spring’ (1013024-29D)

This (Comp 20 & 21) is the “Master Pressure Logic.” The engine’s oil pump is “positive displacement,” meaning its pressure increases with RPM. This valve’s “logic” is to set the *maximum* oil pressure for the entire engine. When pressure exceeds the spring’s rating (e.g., 70 PSI), it pushes the ‘Valve core’ (Comp 21) open, bleeding excess oil back to the oil pan. This is what protects the engine’s seals from blowing out at high RPM.

3. The “Safety Valve” Logic: ‘Safety valve spring’ (1013028-29D) & ‘Plug’ (1013026-29D)

This (Comp 17 & 18) is the “Failsafe Logic.” What if the oil filter (Comp 28) becomes completely clogged? This “safety” or “filter bypass” valve’s “logic” is to open under that extreme pressure. It allows *unfiltered*, dirty oil to bypass the filter and flow to the engine. While dirty oil is bad, “no oil” (from a blocked filter) is instantly catastrophic. This valve in the FAW J6P Engine Oil Cooler is designed to choose the “lesser of two evils” to save the engine.

This final group’s “logic” is to provide all the “plumbing” and “hardware” to connect the FAW J6P Engine Oil Cooler to the block and seal all internal passages.

1. The “Plumbing” Logic: ‘Connecting pipe’ (1013031-36D) & ‘Gaskets’ (1013037-1-29D, 1013036-29D)

This (Comp 1, 4, 5) is the “External Interface Logic.” The ‘Connecting pipe’ is the main “jumper” that moves fluid (likely coolant) from the engine block *to* the cooler module. The ‘Gaskets’ are the critical, high-temperature seals that prevent this fluid from leaking at the connection points.

2. The “Internal Sealing” Logic: (O-rings & Plugs)

This group seals the internal, high-pressure passages. The various ‘O-rings’ (Comp 6, 9, 10, 11, 12) are the “Static Seal Logic.” They are used to seal the cooler core (Comp 27) inside the body (Comp 24) and to seal the various valve plugs (Comp 18). These are what keep the oil and coolant *separate*. The ‘Hex plugs’ (Comp 13) and ‘Copper gaskets’ (Comp 26) are the “Foundry Logic,” sealing the holes drilled during manufacturing.

3. The “Fastener” Logic: (Bolts & Studs)

The assembly uses a mix of ‘Hex flange bolts’ (Comp 2, 8), ‘Bolts’ (Comp 14), and ‘Double-ended studs’ (Comp 3, 19, 22, 23, 25). The “Stud Logic” is superior for a heavy, high-vibration component like the FAW J6P Engine Oil Cooler. The studs are threaded into the engine block, the module is slid on, and nuts are used to clamp it. This provides a more accurate and durable clamping force than simple bolts.

The following table provides the complete, detailed breakdown of all 28 component types identified in this FAW J6P Engine Oil Cooler and Filter Module for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 1013037-1-29D | Gasket – connecting pipe | 1 |

| 2 | Q1840830 | Hexagon flange bolt | 3 |

| 3 | Q1820845 | Hexagon flange stud bolt | 2 |

| 4 | 1013031-36D | Connecting pipe | 1 |

| 5 | 1013036-29D | Gasket – connecting pipe | 1 |

| 6 | CQ7342545C | O-ring for pneumatic | 1 |

| 7 | 1013021-29D | Oil cooler cover plate | 1 |

| 8 | Q1840830 | Hexagon flange bolt | 6 |

| 9 | CQ7342710C | O-ring for pneumatic | 1 |

| 10 | CQ7342300C | O-ring for pneumatic | 1 |

| 11 | CQ7342300C | O-ring for pneumatic | 2 |

| 12 | CQ734180C | O-ring for pneumatic | 4 |

| 13 | Q/WC3410-1994 | Hex plug M24x1.5 | 5 |

| 14 | 1013033-29D | Bolt – oil cooler body | 7 |

| 15 | 1013027-29D | Bypass valve – oil cooler | 1 |

| 16 | 1013022-29D | Nut – oil filter connector | 2 |

| 17 | 1013028-29D | Safety valve spring | 1 |

| 18 | 1013026-29D | Safety valve plug | 1 |

| 19 | Q1820840 | Hexagon flange stud bolt | 2 |

| 20 | 1013024-29D | Pressure regulating valve spring | 1 |

| 21 | 1013023-29D | Pressure regulating valve core | 1 |

| 22 | Q1820870 | Hexagon flange stud bolt | 4 |

| 23 | CQ1200840 | Double-ended stud | 2 |

| 24 | 1013011-36D | Oil cooler body | 1 |

| 25 | CQ1200870 | Double-ended stud | 1 |

| 26 | Q/WC3403-1994 | Copper gasket 24×30 | 6 |

| 27 | 1013010-36D | Oil cooler assy | 1 |

| 28 | 1012010-36D | Oil filter assy | 2 |

The specifications for the FAW J6P Engine Oil Cooler are defined by its function as an integrated thermal, filtration, and pressure-regulation module.

| Vehicle Application | FAW Jiefang CA3250P66K2L1T1E 6×4 Dump Truck |

| System Group | FAW J6P Engine Oil Cooler & Filtration Module |

| Main Cooler Assembly P/N | 1013010-36D |

| Main Housing P/N | 1013011-36D |

| Primary Logic | Thermal Management (Liquid-to-Liquid Heat Exchange) |

| Secondary Logic | Oil Filtration & Oil Pressure Regulation |

| Cooler Type | Plate-Stack Heat Exchanger |

| Filtration Capacity | ‘Oil filter assy’ (1012010-36D) – Qty 2 (Dual Filter) |

| Regulation Valve 1 | ‘Pressure regulating valve’ (1013023-29D) – Master Pressure |

| Regulation Valve 2 | ‘Bypass valve – oil cooler’ (1013027-29D) – Cold Oil Bypass |

| Regulation Valve 3 | ‘Safety valve’ (1013028-29D/1013026-29D) – Filter Clog Failsafe |

| Associated System | Complete FAW J6P Engine Oil Cooler Module |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.