Welcome to this expert deconstruction of the Refrigerador de óleo do motor FAW J6P (Main Assy P/N 1013010-36D). Este é o completo “Lubrificação & Thermal Management Module” for the engine on the FAW Jiefang CA3250P66K2L1T1E 6×4 caminhão despejando.

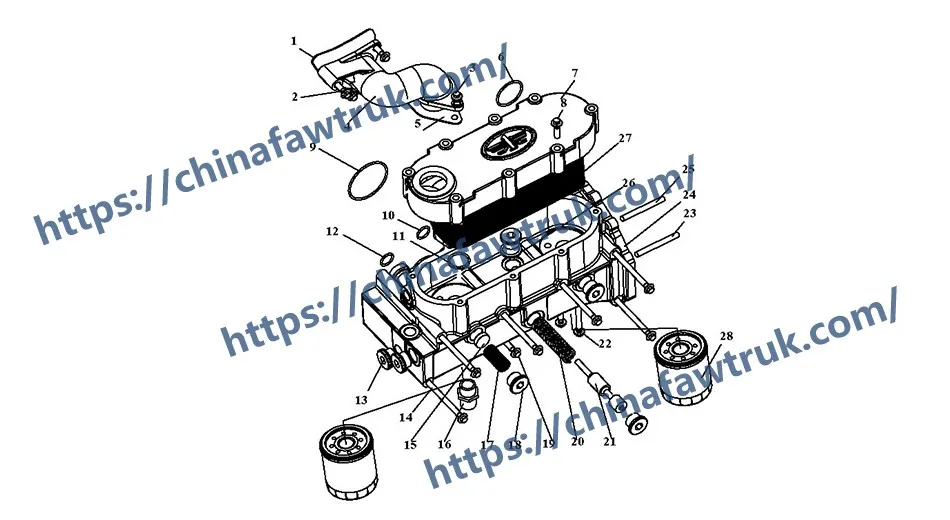

This is not just a simple radiator; it is a highly complex “Logic Assembly” de 28 tipos de componentes, integrating the oil cooler, the oil filter mounts, and multiple pressure-control valves.

O “lógica” disso Refrigerador de óleo do motor FAW J6P é ser o “life-support” system for the engine’s oil, performing three tasks: resfriamento, filtering, and regulating pressure.

O “Thermal Logic” disso Refrigerador de óleo do motor FAW J6P is its most obvious function. Engine oil does more than lubricate; it actively *cools* the pistons and turbocharger. This module is a “liquid-to-liquid” heat exchanger. It runs hot engine oil through a “stack” of plates, while running cold engine coolant through alternating plates. This massive surface area efficiently *transfers heat from the oil to the coolant*, where the truck’s main radiator can dissipate it. Esse “lógica” is the only thing that prevents the oil from overheating, “coking,” and destroying the turbo.

This technical guide is an essential resource for engine rebuilders, machine shop technicians, and fleet parts managers. We will deconstruct the entire 28-component group into its four primary “lógica” sistemas: o “Heat Exchange Logic” (the cooler core and body), o “Filtration Interface Logic” (the filter mounts), o crítico “Fluid Regulation Logic” (the bypass, segurança, and pressure valves), e o “Selagem & Lógica do Fixador” that connects the entire Refrigerador de óleo do motor FAW J6P module to the engine.

This group forms the core purpose of the Refrigerador de óleo do motor FAW J6P: to remove heat from the lubrication circuit.

1. Componentes: ‘Oil cooler assy’ (1013010-36D) & ‘Oil cooler body’ (1013011-36D)

Este é o “Plate-Stack Logic.” The ‘Oil cooler assy’ (Comp. 27) é o completo “essencial”—a sealed “stack” of numerous thin aluminum plates. Isso é “lógica” is to create a massive surface area in a small space. Hot oil flows through one set of plates, while cool engine coolant flows through an alternating set. This is far more efficient than an old “tube-and-fin” cooler. The ‘Oil cooler body’ (Comp. 24) is the cast aluminum “habitação” that this core stack is inserted into. It provides the main

structure, the mounting points, and all the fluid ports for the Refrigerador de óleo do motor FAW J6P.

2. Componente: ‘Oil cooler cover plate’ (1013021-29D)

Esse (Comp. 7) é o “Acesso & Sealing Logic.” This plate is what holds the ‘Oil cooler assy’ (o núcleo) inside the ‘Body’ (Comp. 24). It is sealed with a large O-ring (Comp. 9) and is held on by multiple bolts (Comp. 8). Esse “lógica” makes the Refrigerador de óleo do motor FAW J6P “serviceable”—a technician can remove this cover to replace just the cooler core if it becomes clogged or leaks, without replacing the entire expensive housing.

Este grupo “lógica” is to integrate the engine’s oil filters directly into the Refrigerador de óleo do motor FAW J6P módulo, saving space and simplifying plumbing.

1. Componente: ‘Oil filter assy’ (1012010-36D)

Esse (Comp. 28) é o principal “Filtration Logic.” A lista pede dois (2) destes “spin-on” filtros. O “lógica” do Refrigerador de óleo do motor FAW J6P body is to act as the “docking station” for these filters. Clean oil from the pump flows *into* these filters, passes through the media, and *then* flows to the cooler and the engine.

2. Componente: ‘Nut-oil filter connector’ (1013022-29D)

Esse (Comp. 16) é o “Mounting Logic.” A lista pede dois (2) destes. These are the hollow, rosqueado “nipples” ou “conectores” that are screwed into the cooler body (Comp. 24). The ‘Oil filter assy’ (Comp. 28) spins onto these connectors. Deles “hollow logic” is what allows the oil to flow in and out of the filter. They are held in place by ‘Hex flange nuts’ (Comp. 11).

Este é o “cérebro” do Refrigerador de óleo do motor FAW J6P. It contains three separate valves to manage oil flow in all conditions.

1. O “Cold Start” Lógica: ‘Bypass valve – refrigerador de óleo’ (1013027-29D)

Esse (Comp. 15) é o “Cold Oil Logic.” On a -20°C startup, oil is thick as honey. Forcing it through the tiny plates of the Refrigerador de óleo do motor FAW J6P would create massive back-pressure and starve the engine. Esse “thermal-bypass” válvula “lógica” senses this high pressure (or temperature) and *opens*, allowing the cold, thick oil to *go around* (bypass) the cooler core and flow directly to the engine bearings. As the oil warms up, this valve closes, forcing oil back

through the cooler.

2. O “Pressure Regulation” Lógica: ‘Pressure regulating valve core’ (1013023-29D) & ‘Spring’ (1013024-29D)

Esse (Comp. 20 & 21) é o “Master Pressure Logic.” The engine’s oil pump is “positive displacement,” meaning its pressure increases with RPM. This valve’s “lógica” is to set the *maximum* oil pressure for the entire engine. When pressure exceeds the spring’s rating (Por exemplo, 70 PSI), it pushes the ‘Valve core’ (Comp. 21) abrir, bleeding excess oil back to the oil pan. This is what protects the engine’s seals from blowing out at high RPM.

3. O “Safety Valve” Lógica: ‘Safety valve spring’ (1013028-29D) & ‘Plug’ (1013026-29D)

Esse (Comp. 17 & 18) é o “Failsafe Logic.” What if the oil filter (Comp. 28) becomes completely clogged? Esse “segurança” ou “filter bypass” valve’s “lógica” is to open under that extreme pressure. It allows *unfiltered*, dirty oil to bypass the filter and flow to the engine. While dirty oil is bad, “no oil” (from a blocked filter) is instantly catastrophic. This valve in the Refrigerador de óleo do motor FAW J6P is designed to choose the “lesser of two evils” to save the engine.

Este grupo final “lógica” is to provide all the “encanamento” e “hardware” to connect the Refrigerador de óleo do motor FAW J6P to the block and seal all internal passages.

1. O “Plumbing” Lógica: ‘Connecting pipe’ (1013031-36D) & ‘Gaskets’ (1013037-1-29D, 1013036-29D)

Esse (Comp. 1, 4, 5) é o “External Interface Logic.” The ‘Connecting pipe’ é o principal “jumper” that moves fluid (likely coolant) from the engine block *to* the cooler module. The ‘Gaskets’ are the critical, high-temperature seals that prevent this fluid from leaking at the connection points.

2. O “Internal Sealing” Lógica: (O-rings & Plugs)

This group seals the internal, high-pressure passages. The various ‘O-rings’ (Comp. 6, 9, 10, 11, 12) são os “Static Seal Logic.” They are used to seal the cooler core (Comp. 27) inside the body (Comp. 24) and to seal the various valve plugs (Comp. 18). These are what keep the oil and coolant *separate*. The ‘Hex plugs’ (Comp. 13) and ‘Copper gaskets’ (Comp. 26) são os “Foundry Logic,” sealing the holes drilled during manufacturing.

3. O “Fixador” Lógica: (Parafusos & Pregos)

The assembly uses a mix of ‘Hex flange bolts’ (Comp. 2, 8), ‘Bolts’ (Comp. 14), and ‘Double-ended studs’ (Comp. 3, 19, 22, 23, 25). O “Stud Logic” is superior for a heavy, high-vibration component like the Refrigerador de óleo do motor FAW J6P. The studs are threaded into the engine block, the module is slid on, and nuts are used to clamp it. This provides a more accurate and durable clamping force than simple bolts.

A tabela a seguir fornece o completo, detalhamento de todos 28 tipos de componentes identificados neste Refrigerador de óleo do motor FAW J6P and Filter Module for the FAW Jiefang CA3250P66K2L1T1E 6×4 caminhão despejando.

| Marca | Parte não. | Nome da peça | Quantidade |

|---|---|---|---|

| 1 | 1013037-1-29D | Junta – tubo de conexão | 1 |

| 2 | Q1840830 | Parafuso de flange hexagonal | 3 |

| 3 | Q1820845 | Hexagon flange stud bolt | 2 |

| 4 | 1013031-36D | Connecting pipe | 1 |

| 5 | 1013036-29D | Junta – tubo de conexão | 1 |

| 6 | CQ7342545C | O-ring for pneumatic | 1 |

| 7 | 1013021-29D | Oil cooler cover plate | 1 |

| 8 | Q1840830 | Parafuso de flange hexagonal | 6 |

| 9 | CQ7342710C | O-ring for pneumatic | 1 |

| 10 | CQ7342300C | O-ring for pneumatic | 1 |

| 11 | CQ7342300C | O-ring for pneumatic | 2 |

| 12 | CQ734180C | O-ring for pneumatic | 4 |

| 13 | P/WC3410-1994 | Hex plug M24x1.5 | 5 |

| 14 | 1013033-29D | Parafuso – oil cooler body | 7 |

| 15 | 1013027-29D | Válvula de desvio – refrigerador de óleo | 1 |

| 16 | 1013022-29D | Noz – oil filter connector | 2 |

| 17 | 1013028-29D | Safety valve spring | 1 |

| 18 | 1013026-29D | Safety valve plug | 1 |

| 19 | Q1820840 | Hexagon flange stud bolt | 2 |

| 20 | 1013024-29D | Pressure regulating valve spring | 1 |

| 21 | 1013023-29D | Pressure regulating valve core | 1 |

| 22 | Q1820870 | Hexagon flange stud bolt | 4 |

| 23 | CQ1200840 | Double-ended stud | 2 |

| 24 | 1013011-36D | Oil cooler body | 1 |

| 25 | CQ1200870 | Double-ended stud | 1 |

| 26 | Q/WC3403-1994 | Copper gasket 24×30 | 6 |

| 27 | 1013010-36D | Oil cooler assy | 1 |

| 28 | 1012010-36D | Oil filter assy | 2 |

As especificações para o Refrigerador de óleo do motor FAW J6P are defined by its function as an integrated thermal, filtração, and pressure-regulation module.

| Aplicação em veículos | FAW Jiefang CA3250P66K2L1T1E 6×4 Caminhão basculante |

| Grupo de sistemas | Refrigerador de óleo do motor FAW J6P & Filtration Module |

| Main Cooler Assembly P/N | 1013010-36D |

| Carcaça Principal P/N | 1013011-36D |

| Lógica Primária | Thermal Management (Liquid-to-Liquid Heat Exchange) |

| Lógica Secundária | Oil Filtration & Oil Pressure Regulation |

| Cooler Type | Plate-Stack Heat Exchanger |

| Filtration Capacity | ‘Oil filter assy’ (1012010-36D) – Quantidade 2 (Dual Filter) |

| Regulation Valve 1 | ‘Pressure regulating valve’ (1013023-29D) – Master Pressure |

| Regulation Valve 2 | ‘Bypass valve – refrigerador de óleo’ (1013027-29D) – Desvio de óleo frio |

| Regulation Valve 3 | ‘Safety valve’ (1013028-29D/1013026-29D) – Filter Clog Failsafe |

| Sistema Associado | Completo Refrigerador de óleo do motor FAW J6P Módulo |

Peças FAW, incluindo o conjunto do bloco de cilindros, são embalados com cuidado para garantir uma entrega segura. Cada componente é protegido por materiais de proteção para evitar danos durante o transporte. A rede logística garante envios pontuais em todo o mundo, apoiando operações de manutenção eficientes. Abaixo está uma imagem ilustrando a embalagem padrão para peças de caminhão FAW, mostrando a atenção aos detalhes no manuseio e armazenamento.

Esta abordagem de embalagem minimiza o risco de corrosão ou danos por impacto, garantindo que peças como o conjunto do bloco de cilindros FAW cheguem em perfeitas condições. Os clientes podem confiar na logística da FAW para obter qualidade e confiabilidade consistentes.