Welcome to this expert deconstruction of the FAW J6P Air-Conditioning Compressor (Main Assy P/N 8103020-70A). This is the “comfort core” and primary “refrigerant pump” for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck.

This component is a “Logic Assembly” of 5 critical parts. Its “logic” is to convert rotational power from the engine’s accessory belt into high-pressure refrigerant, which is the “lifeblood” of the cab’s A/C system.

The “Parasitic Load Logic” is the key to this FAW J6P Air-Conditioning Compressor. This is the single *largest* “parasitic load” in the engine’s accessory drive system. It is driven by the ‘Multi-groove belt’ (P/N 1023021-36D) but features an “Electromagnetic Clutch Logic.” This “clutch” allows the compressor’s pulley to “free-spin” 99% of the time, creating almost no drag on the engine. When the driver presses the A/C button, this clutch “slams” shut, placing an *instant* 10-15 horsepower load on the engine. This “shock load” is what the ‘Automatic Tensioner’ (P/N 1023010-36D) is designed to handle.

This technical guide is an essential resource for chassis technicians, fleet maintenance managers, and parts specialists. We will deconstruct the entire 5-component-type group. We will analyze the “Refrigerant Compression Logic” (the main compressor assembly itself), the “Structural Support Logic” (the anti-vibration bracket), and the “Critical Fastener Logic” (the high-tensile hardware) that mounts the FAW J6P Air-Conditioning Compressor to the engine.

This component is the main assembly and the functional “heart” of the entire cab comfort system. The FAW J6P Air-Conditioning Compressor is a complex, high-pressure pump.

1. Component: ‘A/C compressor assy’ (8103020-70A)

This (Comp 1) is the complete assembly. Its “Refrigerant Logic” is to be a “positive displacement” pump. It sucks in *low-pressure, gaseous* refrigerant (like R134a) from the “evaporator” (the cold part in the dashboard). Internally, it uses a “Wobble Plate” or “Swash Plate” logic. The “logic” is that the engine’s belt spins a pulley, which turns a central shaft. This shaft has a “wobble plate” mounted at an angle. As this plate “wobbles,” it drives a series of 5 or 7 tiny “pistons” back and forth in their cylinders, compressing the refrigerant gas.

This “Compression Logic” turns the low-pressure gas into a *high-pressure, high-temperature* (superheated) gas. This “hot gas” is then sent to the “condenser” (the radiator at the front of the truck) where it releases its heat and turns back into a liquid, completing the cycle. The internal components of the FAW J6P Air-Conditioning Compressor are lubricated by a special “PAG oil” that circulates *with* the refrigerant, so a refrigerant leak is also an *oil leak* for the compressor.

2. The “Electromagnetic Clutch Logic” (Internal to Comp 1)

This is the “Interface Logic” for the FAW J6P Air-Conditioning Compressor. The pulley on the front of the compressor is not directly connected to the internal shaft. It “free-spins” on its own bearing. This “logic” means that when the A/C is off, the compressor is 100% disengaged and creates zero “parasitic” load on the engine.

When the driver presses the A/C button, an “electromagnet” is energized. This powerful magnet “pulls” a “clutch plate” outwards, “slamming” it against the spinning pulley. This “Clutch Logic” is what locks the pulley to the compressor’s internal shaft, engaging the pump. This “slam” or “shock load” is the most demanding event for the engine’s serpentine belt, and the *reason* a heavy-duty ‘Automatic tensioner’ is required for the FAW J6P Air-Conditioning Compressor to function without squealing or breaking the belt.

This component’s “logic” is to provide a rigid, perfectly aligned, and vibration-proof foundation for the FAW J6P Air-Conditioning Compressor.

1. Component: ‘Support – A/C compressor’ (8103061-70A)

This (Comp 2) is the “Anti-Fatigue Logic.” The FAW J6P Air-Conditioning Compressor (Comp 1) is a heavy component that also has internal oscillating pistons, creating its own vibration. It *cannot* be bolted directly to a thin “timing cover” or a weak point on the engine block.

This “Support” is a heavy-duty, cast-iron bracket. Its “logic” is to bolt to the main ‘Front-end system support’ (P/N 1023011-36D) or directly to the engine block’s structural “bosses.” This provides a “Shock-Proof Foundation” that can withstand the “slam” of the clutch engaging and the constant, high-frequency vibrations from the engine.

The “Alignment Logic” is its second, equally critical function. The serpentine belt must run with perfect “parallel” alignment. This ‘Support’ is machined to *guarantee* that the FAW J6P Air-Conditioning Compressor pulley is on the exact same plane as the crankshaft pulley, alternator pulley, and water pump pulley. A misaligned compressor (from a bent or cracked bracket) will “walk” the belt off the pulley or “shred” its edges in a matter of hours. This makes the ‘Support’ a precision-critical component.

This final group’s “logic” is to provide the high-tensile “clamping force” required to hold the entire FAW J6P Air-Conditioning Compressor assembly in place against all operational forces.

1. Components: ‘Hexagon head bolt’ (CQ15010110) & ‘Hexagon flange nut’ (CQ39610)

The list calls for two (2) bolts (Comp 3) and two (2) nuts (Comp 4). This “Through-Bolt Logic” is the strongest possible mounting method. This “logic” implies that the ‘Support’ bracket (Comp 2) is mounted to the *main* engine accessory bracket using two long “studs” or “through-bolts” that are secured by these nuts. This “Nut & Bolt” system provides a massive, vibration-resistant clamping force.

2. Component: ‘Hexagon flange bolt, coarse shank (standard type)’ (Q1841230)

The list calls for one (1) of these (Comp 5). This is the “Primary Compressor Mount Bolt.” Its “logic” is to be the main fastener that passes *through* the FAW J6P Air-Conditioning Compressor (Comp 1) and threads *into* the ‘Support’ (Comp 2). The “Flange Logic” is that the built-in washer provides a large friction surface that prevents the bolt from “walking” loose from vibration. The “Coarse Shank Logic” means it is a high-strength bolt designed to withstand the “sheer force” (the side-to-side force) of the belt tension. These three sets of hardware are all that hold the heavy, high-load FAW J6P Air-Conditioning Compressor in place.

The following table provides the complete, detailed breakdown of all 5 component types identified in this FAW J6P Air-Conditioning Compressor assembly for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck.

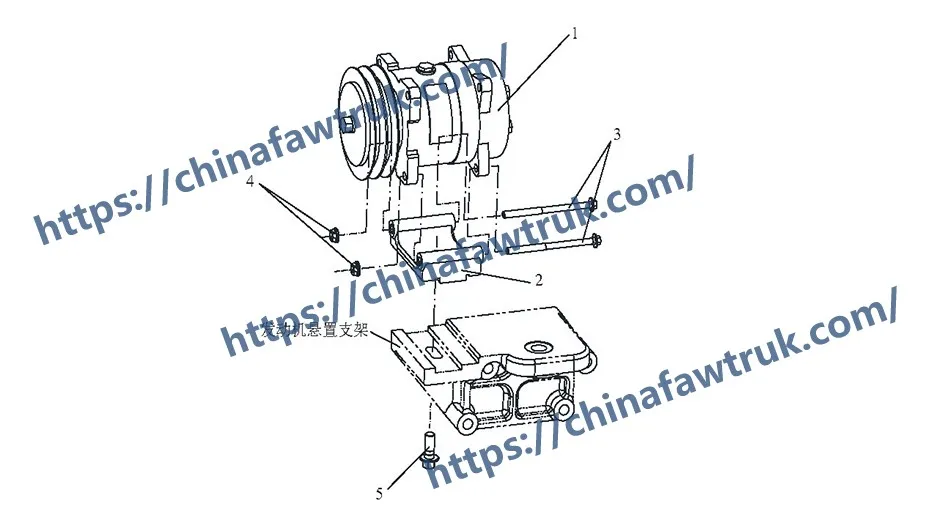

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 8103020-70A | A/C compressor assy | 1 |

| 2 | 8103061-70A | Support – A/C compressor | 1 |

| 3 | CQ15010110 | Hexagon head bolt | 2 |

| 4 | CQ39610 | Hexagon flange nut | 2 |

| 5 | Q1841230 | Hexagon flange bolt, coarse shank (standard type) | 1 |

The specifications for the FAW J6P Air-Conditioning Compressor are defined by its function as the primary refrigerant pump for the cab’s comfort system.

| Vehicle Application | FAW Jiefang CA3250P66K2L1T1E 6×4 Dump Truck |

| System Group | FAW J6P Air-Conditioning Compressor Assembly |

| Main Compressor P/N | 8103020-70A |

| Primary Logic | Refrigerant Compression (Low-Pressure Gas to High-Pressure Gas) |

| Pump Type | Vane or Swash/Wobble Plate Piston Pump |

| Drive System | Engine Serpentine Belt (Part of FEAD) |

| Engagement System | Electromagnetic Clutch Logic (On/Off) |

| Structural Mount | ‘Support – A/C compressor’ (8103061-70A) |

| Mounting Hardware | CQ15010110 (2), CQ39610 (2), Q1841230 (1) |

| Associated System | Part of the FAW J6P Front Wheel Assembly (FEAD) |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.