Bem-vindo a esta desconstrução especializada do Compressor de ar condicionado FAW J6P (Conjunto principal P/N 8103020-70A). Este é o “comfort core” and primary “refrigerant pump” para o FAW Jiefang CA3250P66K2L1T1E 6×4 caminhão despejando.

Este componente é um “Montagem Lógica” de 5 critical parts. Isso é “lógica” is to convert rotational power from the engine’s accessory belt into high-pressure refrigerant, qual é o “lifeblood” of the cab’s A/C system.

O “Lógica de carga parasita” is the key to this Compressor de ar condicionado FAW J6P. This is the single *largest* “parasitic load” in the engine’s accessory drive system. It is driven by the ‘Multi-groove belt’ (P/N 1023021-36D) but features an “Electromagnetic Clutch Logic.” Esse “embreagem” allows the compressor’s pulley to “free-spin” 99% of the time, creating almost no drag on the engine. Quando o motorista pressiona o botão A/C, this clutch “bate” fechar, colocando um *instantâneo* 10-15 horsepower load on the engine. Esse “shock load” is what the ‘Automatic Tensioner’ (P/N 1023010-36D) is designed to handle.

Este guia técnico é um recurso essencial para técnicos de chassis, gerentes de manutenção de frota, e especialistas em peças. We will deconstruct the entire 5-component-type group. Iremos analisar o “Refrigerant Compression Logic” (the main compressor assembly itself), o “Structural Support Logic” (the anti-vibration bracket), e o “Critical Fastener Logic” (the high-tensile hardware) that mounts the Compressor de ar condicionado FAW J6P para o motor.

This component is the main assembly and the functional “coração” of the entire cab comfort system. O Compressor de ar condicionado FAW J6P é um complexo, high-pressure pump.

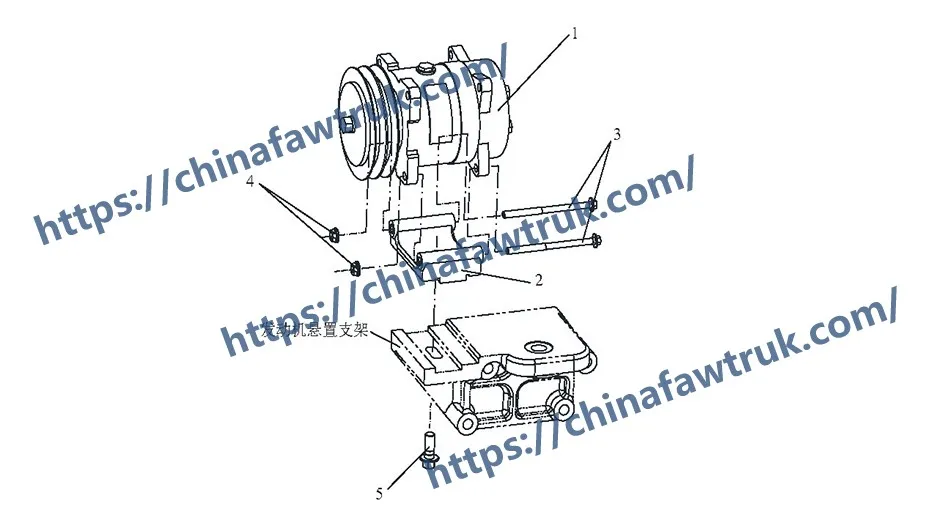

1. Componente: ‘Conjunto do compressor A/C’ (8103020-70A)

Esse (Comp. 1) é a montagem completa. Isso é “Refrigerant Logic” é ser um “positive displacement” bombear. It sucks in *low-pressure, gaseous* refrigerant (like R134a) do “evaporator” (the cold part in the dashboard). Internamente, it uses a “Placa oscilante” ou “Prato oscilante” lógica. O “lógica” is that the engine’s belt spins a pulley, which turns a central shaft. This shaft has a “placa oscilante” mounted at an angle. As this plate “wobbles,” it drives a series of 5 ou 7 tiny “Pistons” back and forth in their cylinders, compressing the refrigerant gas.

Esse “Lógica de compressão” turns the low-pressure gas into a *high-pressure, high-temperature* (superheated) gás. Esse “gás quente” is then sent to the “condensador” (the radiator at the front of the truck) where it releases its heat and turns back into a liquid, completing the cycle. Os componentes internos do Compressor de ar condicionado FAW J6P are lubricated by a special “PAG oil” that circulates *with* the refrigerant, so a refrigerant leak is also an *oil leak* for the compressor.

2. O “Electromagnetic Clutch Logic” (Interno para Comp 1)

Este é o “Interface Logic” para o Compressor de ar condicionado FAW J6P. The pulley on the front of the compressor is not directly connected to the internal shaft. Isto “rodadas grátis” on its own bearing. Esse “lógica” means that when the A/C is off, the compressor is 100% disengaged and creates zero “parasita” load on the engine.

Quando o motorista pressiona o botão A/C, um “electromagnet” is energized. This powerful magnet “puxa” a “placa de embreagem” outwards, “batendo” it against the spinning pulley. Esse “Clutch Logic” is what locks the pulley to the compressor’s internal shaft, engaging the pump. Esse “slam” ou “shock load” is the most demanding event for the engine’s serpentine belt, and the *reason* a heavy-duty ‘Automatic tensioner’ is required for the Compressor de ar condicionado FAW J6P to function without squealing or breaking the belt.

Este componente “lógica” é fornecer uma rígida, perfectly aligned, and vibration-proof foundation for the Compressor de ar condicionado FAW J6P.

1. Componente: ‘Support – A/C compressor’ (8103061-70A)

Esse (Comp. 2) é o “Anti-Fatigue Logic.” O Compressor de ar condicionado FAW J6P (Comp. 1) is a heavy component that also has internal oscillating pistons, creating its own vibration. It *cannot* be bolted directly to a thin “timing cover” or a weak point on the engine block.

Esse “Apoiar” é um serviço pesado, cast-iron bracket. Isso é “lógica” is to bolt to the main ‘Front-end system support’ (P/N 1023011-36D) or directly to the engine block’s structural “bosses.” This provides a “Shock-Proof Foundation” that can withstand the “slam” of the clutch engaging and the constant, high-frequency vibrations from the engine.

O “Lógica de Alinhamento” é o segundo, equally critical function. The serpentine belt must run with perfect “paralelo” alinhamento. This ‘Support’ is machined to *guarantee* that the Compressor de ar condicionado FAW J6P pulley is on the exact same plane as the crankshaft pulley, alternator pulley, and water pump pulley. A misaligned compressor (from a bent or cracked bracket) vai “andar” the belt off the pulley or “shred” its edges in a matter of hours. This makes the ‘Support’ a precision-critical component.

Este grupo final “lógica” is to provide the high-tensile “clamping force” required to hold the entire Compressor de ar condicionado FAW J6P assembly in place against all operational forces.

1. Componentes: ‘Hexagon head bolt’ (CQ15010110) & ‘Hexagon flange nut’ (CQ39610)

A lista pede dois (2) parafusos (Comp. 3) e dois (2) nozes (Comp. 4). Esse “Through-Bolt Logic” is the strongest possible mounting method. Esse “lógica” implies that the ‘Support’ suporte (Comp. 2) is mounted to the *main* engine accessory bracket using two long “pregos” ou “through-bolts” that are secured by these nuts. Esse “Noz & Parafuso” system provides a massive, vibration-resistant clamping force.

2. Componente: 'Parafuso de flange hexagonal, coarse shank (tipo padrão)’ (Q1841230)

The list calls for one (1) destes (Comp. 5). Este é o “Primary Compressor Mount Bolt.” Isso é “lógica” is to be the main fastener that passes *through* the Compressor de ar condicionado FAW J6P (Comp. 1) and threads *into* the ‘Support’ (Comp. 2). O “Lógica de Flange” is that the built-in washer provides a large friction surface that prevents the bolt from “andando” loose from vibration. O “Coarse Shank Logic” means it is a high-strength bolt designed to withstand the “sheer force” (the side-to-side force) of the belt tension. These three sets of hardware are all that hold the heavy, alta carga Compressor de ar condicionado FAW J6P no lugar.

A tabela a seguir fornece o completo, detalhamento de todos 5 tipos de componentes identificados neste Compressor de ar condicionado FAW J6P montagem para o FAW Jiefang CA3250P66K2L1T1E 6×4 caminhão despejando.

| Marca | Parte não. | Nome da peça | Quantidade |

|---|---|---|---|

| 1 | 8103020-70A | Conjunto de compressor de ar condicionado | 1 |

| 2 | 8103061-70A | Apoiar – A/C compressor | 1 |

| 3 | CQ15010110 | Parafuso da cabeça do hexágono | 2 |

| 4 | CQ39610 | Noz de flange hexágono | 2 |

| 5 | Q1841230 | Parafuso de flange hexagonal, coarse shank (tipo padrão) | 1 |

As especificações para o Compressor de ar condicionado FAW J6P are defined by its function as the primary refrigerant pump for the cab’s comfort system.

| Aplicação em veículos | FAW Jiefang CA3250P66K2L1T1E 6×4 Caminhão basculante |

| Grupo de sistemas | Compressor de ar condicionado FAW J6P Conjunto |

| Main Compressor P/N | 8103020-70A |

| Lógica Primária | Refrigerant Compression (Low-Pressure Gas to High-Pressure Gas) |

| Tipo de bomba | Vane or Swash/Wobble Plate Piston Pump |

| Sistema de acionamento | Correia serpentina do motor (Part of FEAD) |

| Sistema de Engajamento | Electromagnetic Clutch Logic (On/Off) |

| Montagem Estrutural | ‘Support – A/C compressor’ (8103061-70A) |

| Hardware de montagem | CQ15010110 (2), CQ39610 (2), Q1841230 (1) |

| Sistema Associado | Parte do Conjunto de roda dianteira FAW J6P (FEAD) |

Peças FAW, incluindo o conjunto do bloco de cilindros, são embalados com cuidado para garantir uma entrega segura. Cada componente é protegido por materiais de proteção para evitar danos durante o transporte. A rede logística garante envios pontuais em todo o mundo, apoiando operações de manutenção eficientes. Abaixo está uma imagem ilustrando a embalagem padrão para peças de caminhão FAW, mostrando a atenção aos detalhes no manuseio e armazenamento.

Esta abordagem de embalagem minimiza o risco de corrosão ou danos por impacto, garantindo que peças como o conjunto do bloco de cilindros FAW cheguem em perfeitas condições. Os clientes podem confiar na logística da FAW para obter qualidade e confiabilidade consistentes.