Welcome to this deep dive on the Stop Block-Front Windscreen for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck. This may seem like a simple part, but it is a critical component for protecting the windshield and cab structure. This guide will analyze this single, essential part type to ensure correct service.

The Stop Block-Front Windscreen is a specialized, high-density energy-absorbing component. Its primary role is to act as the final, engineered contact point between the tilting cab and the fixed body, specifically to protect the front windscreen glass. When the cab is lowered, this block prevents a hard, jarring “metal-on-metal” impact.

This part is vital. Without the Stop Block-Front Windscreen, the repeated shock and vibration of lowering the cab would eventually fatigue the windscreen’s urethane seal, leading to leaks, or even crack the glass itself. It also prevents damage to the cab’s hinge and latch mechanisms.

This teardown will analyze the part (5206037-A01J) in detail. We will explore its critical material science, its precise placement, and its common failure modes. For a technician, a missing or damaged Stop Block-Front Windscreen is a non-negotiable replacement item to prevent costly, cascading damage to the vehicle’s cab and windscreen.

This system consists of a single component type, used in duplicate for stability. It is the primary energy-absorbing buffer for the truck cab.

1. Component: ‘Stop Block-Front Windscreen (Assembled per 5206003-A01J/A)’ (5206037-A01J) – Qty 2

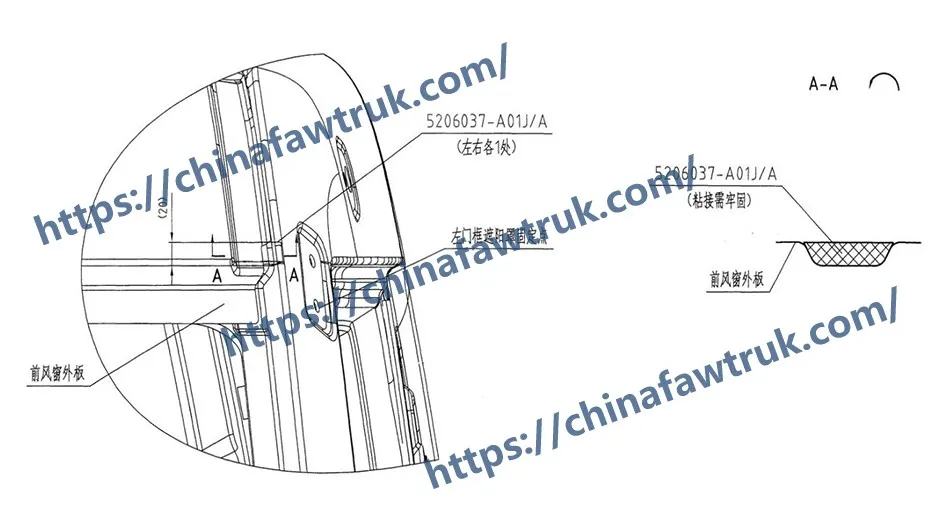

This (Mark 1) is the core component. The part number `5206037-A01J` refers to the individual block itself. The quantity of 2 confirms this is a symmetrical system, with one Stop Block-Front Windscreen used on the left and one on the right side of the cab’s lower frame.

The Assembly Note Logic: The note “Assembled per 5206003-A01J/A” is an important instruction for the technician or assembly line. It signifies that this block is not simply bolted on; it is part of a larger assembly standard (5206003-A01J/A). This standard likely defines the *method* of installation, specifying the exact hardware, torque values, or even the use of an adhesive or thread-locker required to create the complete, reliable windscreen protection system.

The Symmetrical Logic: The use of two blocks is a critical engineering decision for stability. By having two distinct contact points (left and right), the substantial weight and load of the descending cab is distributed evenly across the chassis. This prevents the cab from twisting or rocking as it settles. A single, central block would act as a pivot point, creating instability and putting asymmetric stress on the cab’s locking mechanism and the windscreen’s flexible urethane seal.

The Service Logic: Because of this symmetrical-load logic, a technician must *always* replace these blocks in pairs. If one Stop Block-Front Windscreen is found to be damaged, flattened, or missing, it is a certainty that the other block has been subjected to double its intended load and is also fatigued or damaged. Replacing only one will result in an uneven cab landing, which defeats the purpose of the system, creates new stress points, and will lead to the premature failure of the new part.

A Stop Block-Front Windscreen is a component defined by its material science. It is not made of simple plastic or basic rubber.

The Material Logic: This component is manufactured from a high-density, high-durometer elastomer. The most common materials are EPDM (ethylene propylene diene monomer) rubber or a specialized microcellular polyurethane. This material is chosen for its specific and crucial properties.

The Energy Absorption Logic: The material’s most important trait is its “compression set resistance.” It is designed to compress significantly under a heavy load (the weight of the cab) and then return to its original shape. This action dissipates the kinetic energy, providing a soft, controlled landing. A solid, rigid plastic block would be too hard, transmitting the shock directly to the windscreen. A soft foam would collapse and offer no protection. This Stop Block-Front Windscreen is the perfect, engineered middle-ground.

The Durability Logic: EPDM or industrial polyurethane is chosen for its extreme durability. This Stop Block-Front Windscreen must be 100% waterproof and, more importantly, resistant to all common automotive fluids. It must withstand daily exposure to hydraulic fluid (from the cab tilt system), diesel, engine oil, and road salt without swelling, cracking, or turning brittle. This ensures a service life of many years and thousands of cab-tilt cycles.

The Design Logic: The physical shape of the Stop Block-Front Windscreen is precisely engineered. It is not a simple cube. It features a specific, angled or contoured “contact face” designed to mate perfectly with a designated “landing pad” on the truck’s chassis. The base of the block is often designed with a “T-slot” or “mushroom” shape that is mechanically locked into a bracket on the cab frame. This design, in addition to any bolts, prevents the block from being “peeled” or “sheared” off its mount by lateral forces.

The function of the Stop Block-Front Windscreen is entirely dependent on its precise placement.

The Placement Logic: These two blocks are mounted on the lowest forward-most edge of the cab’s structural sub-frame, typically located directly beneath the left and right corners of the front windscreen. This location is calibrated at the factory to be the very first part of the cab to make contact with the chassis frame as the cab is hydraulically lowered from its tilted position.

The Windscreen Protection Logic: The primary and most obvious purpose is to protect the windscreen. The windscreen is a large, expensive, and structurally-critical piece of laminated glass. It is “floated” in a flexible urethane seal. Any direct impact, or any significant “tweaking” of the cab frame as it slams shut, can easily focus-fracture the glass, causing a crack. This Stop Block-Front Windscreen ensures the cab *never* travels past its designated, safe “home” position, saving the windscreen from impact.

The Hinge & Latch Protection Logic: A crucial secondary function of the Stop Block-Front Windscreen is to protect the cab’s main pivot hinges (at the front) and the locking mechanism (at the rear). By absorbing the final impact of the descending cab, these blocks dramatically reduce the “slamming” force and shock load that would otherwise be transferred to these critical components. This reduction in impact load increases the service life of the hinge pins, bushings, and the latch hooks, preventing wear and misalignment.

The NVH Logic: These blocks also serve a vital noise, vibration, and harshness (NVH) function. When the cab is fully lowered and latched, the blocks remain under a slight “pre-load” compression. This constant, upward spring-like pressure ensures the front of the cab is held firmly against the chassis, eliminating any micro-movements. This prevents the cab’s front end from squeaking, “chucking,” or rattling against the chassis while driving over rough roads.

The Stop Block-Front Windscreen is a wear item and must be inspected regularly.

The Failure Mode Logic: After thousands of cycles of tilting and lowering the cab, the elastomer will eventually fatigue. The most common failures are:

1. **Compression Set:** The material loses its “springiness” and becomes permanently flattened. It no longer offers any cushioning, effectively acting as a hard, useless puck.

2. **Cracking/Tearing:** The material becomes brittle from age, ozone, and fluid exposure, and begins to crack, tear, or delaminate from its mounting base.

3. **Missing:** The most severe failure, where a fatigued block has been completely torn from its mount and is gone.

The Inspection Logic: Any technician performing service that requires tilting the cab has a professional responsibility to visually inspect these two blocks as part of the procedure. If the blocks are visibly cracked, flattened (showing compression set), or missing, they must be replaced. This is a critical safety-of-service item.

The Replacement Logic: As the part diagram indicates, the Stop Block-Front Windscreen is a single component (5206037-A01J). Replacement involves unbolting or un-clipping the old block from its mount on the cab frame and installing the new one, following the assembly standard (5206003-A01J/A). As stated in Core 1, they must be replaced in pairs to ensure an even landing.

The Consequence Logic: Ignoring a failed Stop Block-Front Windscreen is a costly mistake. The immediate consequence will be a harsh “clang” when the cab is lowered. The long-term, expensive consequences are a cracked windscreen (a very expensive repair), “egged” or damaged cab hinge bushings, or a failed cab latch mechanism, all of which are far more complex and costly to fix than replacing these simple, essential blocks.

The following table provides the complete, detailed breakdown of the 1 component type specified for the Stop Block-Front Windscreen system on the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 5206037-A01J | Stop Block-Front Windscreen (Assembled per 5206003-A01J/A) | 2 |

The specifications for the Stop Block-Front Windscreen are defined by its role as a critical, energy-absorbing buffer for the cab.

| Vehicle Application | FAW Jiefang CA3250P66K2L1T1E 6×4 Dump Truck |

| System Group | Stop Block-Front Windscreen |

| Primary Component | ‘Stop Block-Front Windscreen’ (5206037-A01J) |

| Material | High-Durometer EPDM Rubber or Microcellular Polyurethane |

| Key Feature 1 | High Energy Absorption |

| Key Feature 2 | High Compression Set Resistance |

| Key Feature 3 | Chemical & Fluid Resistant (Oil, Diesel, Hydraulic) |

| Function 1 | Protects Front Windscreen from Impact |

| Function 2 | Protects Cab Hinges & Latches from Shock Load |

| Function 3 | NVH Control (Prevents Cab Rattles) |

| Service Note | Must be replaced in pairs if damaged, flat, or missing. |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.