Welcome to this detailed analysis of the Front Emblem-Front Bumper Cover system for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck. This component group is the “face” of the vehicle, a critical element of its brand identity. This guide will deconstruct the 2 key parts that create this assembly.

The Front Emblem-Front Bumper Cover is the primary identifying feature of the FAW J6P. It is more than just a logo; it is an engineered, multi-piece assembly designed to withstand harsh environments while maintaining a premium, flawless appearance. It is the centerpiece of the cab’s front outer panel.

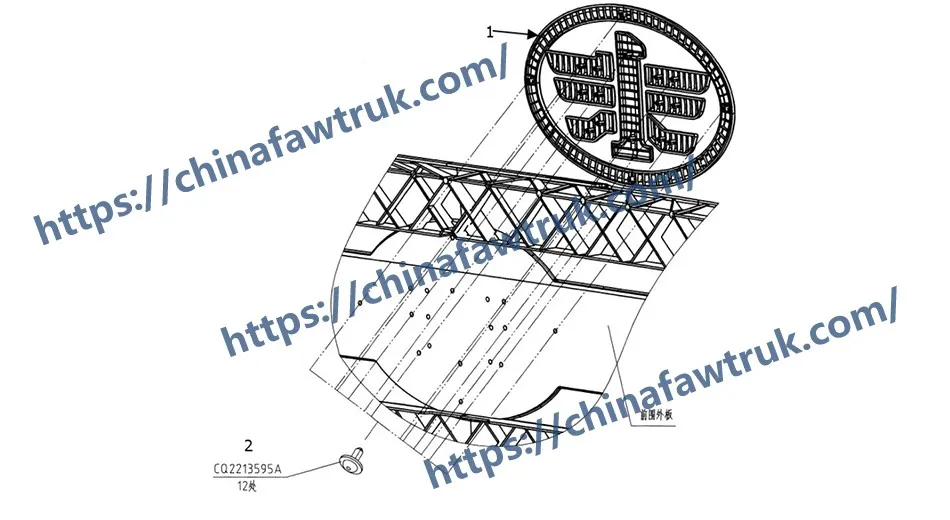

This teardown will analyze the Front Emblem (5302801-B26) and its specialized mounting hardware (CQ2213595A). We will explore the complex manufacturing process of the emblem, from its ABS substrate to its multi-layer chrome plating, and the critical role of its combination-screw fasteners.

For a technician or a fleet owner, the Front Emblem-Front Bumper Cover represents the truck’s professionalism. A damaged, peeling, or missing emblem significantly degrades the vehicle’s appearance. Understanding its robust mounting system is key to replacing it correctly, ensuring a secure, vibration-free fit that lasts.

This component is the “jewelry” of the Front Emblem-Front Bumper Cover system. It is a complex, multi-layered component engineered for durability and high visual impact.

1. Component: ‘Front Emblem’ (5302801-B26) – Qty 1

This (Mark 1) is the complete Front Emblem. It is not a simple sticker or a single piece of plastic. It is a sophisticated assembly manufactured to the highest automotive-grade standards.

The Substrate Logic: The foundation of the emblem is an injection-molded substrate made from high-grade, virgin ABS (Acrylonitrile Butadiene Styrene). This material is chosen for its excellent dimensional stability (it won’t warp in the sun), its superior surface quality, and its ability to perfectly bond with the electroplated layers.

The Electroplating Logic: The brilliant “chrome” finish is not paint. It is a complex, multi-step electroplating process. The ABS substrate is first etched, then dipped in a series of baths to apply a layer of nickel (for adhesion and corrosion resistance), followed by a layer of copper (for a smooth, brilliant surface), and finally the top layer of chromium (for the blue-white shine and surface hardness).

This process is what gives the Front Emblem-Front Bumper Cover its true metallic luster and its resistance to stone chips and environmental fallout.

The UV Protection Logic: After electroplating, the entire Front Emblem is coated with a final, transparent automotive-grade lacquer. This clear-coat is the emblem’s primary defense against the elements. It contains high levels of UV inhibitors to prevent the sun from “yellowing” or “fogging” the chrome and plastic substrate over time. It also provides a “wet look” and makes the emblem easier to clean.

The Mounting Boss Logic: The reverse side of the emblem features multiple (in this case, 10) molded-in “bosses” or “studs.” These are hollow plastic cylinders that serve two functions: 1. They act as alignment pins, fitting into pre-drilled holes on the bumper cover to ensure the emblem is *perfectly* level and centered. 2. They act as the “female” threads for the tapping screws (Core 2).

The Service Logic: The Front Emblem is a non-serviceable unit. If the chrome is peeling, cracked from a stone chip, or damaged by harsh chemicals, the entire 5302801-B26 part must be replaced. Replacement is a key part of collision repair to restore the vehicle’s “like-new” appearance.

This logic describes the “Front Bumper Cover” itself, which is the “Front Outer Panel” (前围外板) referenced in the diagram’s title. This panel is the host for the entire Front Emblem-Front Bumper Cover system.

The Material Logic: The bumper cover is a very large, complex molding, typically made of a flexible, impact-resistant polymer like TPO (Thermoplastic Olefin) or a PC/PBT (Polycarbonate/Polybutylene Terephthalate) blend. This material is chosen for its “impact memory.”

The Impact Memory Logic: TPO is used on dump trucks because it can deform significantly under a low-speed impact (e.g., bumping a pile of gravel) and then return to its original shape. This flexibility prevents the costly cracking and shattering associated with more rigid plastics, saving the panel from minor impacts.

The “Class-A” Surface Logic: The exterior of the panel is a “Class-A” finish. This is an automotive manufacturing term for a surface that is perfectly smooth, free of any mold marks, sinks, or blemishes, and is ready to accept a high-quality, body-color paint finish. The Front Emblem-Front Bumper Cover relies on this perfect surface for its premium fit.

The Precision Logic: This Front Bumper Cover is not just a cosmetic skin. It is an engineered component with hundreds of integrated features. It has molded-in mounting points for the steel reinforcement bar, the headlights, the main grille, and, most importantly, the Front Emblem.

The factory molds 10 precision pilot holes into the panel. These holes perfectly match the 10 mounting bosses on the back of the emblem (Core 1). This precision-engineering is what guarantees that the emblem is installed perfectly straight, centered, and level on every single truck that leaves the factory.

These are the critical fasteners that physically bond the emblem (Core 1) to the bumper cover (Core 2), completing the Front Emblem-Front Bumper Cover assembly.

1. Component: ‘Cross recessed pan head tapping screw and plain washer assembly’ (CQ2213595A) – Qty 10

This (Mark 2) is the complete set of 10 identical fasteners. The part number designates a “combination” or “Sems” screw.

The Combination Logic: The term “assembly” (组合件) is key. This is not a separate screw and washer. It is a pre-assembled component where the plain washer is “captive” under the screw head and cannot fall off.

This design is essential for ease of manufacturing. A technician (or robot) on the assembly line, working from behind the bumper cover, can easily install the screw without having to fumble with a separate, tiny washer. It makes the assembly of the Front Emblem-Front Bumper Cover faster and more reliable.

The Load Distribution Logic: The “plain washer” (平垫圈) is a critical engineering component. Its job is to distribute the clamping force of the screw over a wider surface area. Without this washer, the small screw head would concentrate all its force on a narrow ring, which would create a stress point and crack the emblem’s plastic mounting boss. The washer prevents this, ensuring a secure, long-lasting fit.

The “Tapping Screw” Logic: These are “self-tapping” (自攻螺钉). The screws have hardened threads designed to be driven directly into the softer plastic of the emblem’s mounting bosses (Core 1). They cut their own threads as they are installed, creating an extremely tight, precise, and vibration-resistant connection.

The Quantity Logic: Ten fasteners for a single emblem may seem excessive, but it is intentional. The Front Emblem is large and flat, exposing it to significant wind-buffeting at highway speeds. Using 10 fastening points ensures the emblem is held perfectly flush against the bumper cover, with no “lifting” or “flexing” at the edges. This prevents wind noise, rattles, and moisture/ice from getting behind the emblem.

The Service Logic: These fasteners are the key to replacing a damaged Front Emblem. A technician must gain access to the *back* of the Front Emblem-Front Bumper Cover to remove these 10 screws. When installing the new emblem, these screws must be tightened carefully by hand. Using a power tool can easily over-torque them, stripping the new plastic bosses and destroying the brand-new emblem.

The following table provides the complete, detailed breakdown of all 2 component types specified for the Front Emblem-Front Bumper Cover system on the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 5302801-B26 | Front Emblem | 1 |

| 2 | CQ2213595A | Cross recessed pan head tapping screw and plain washer assembly | 10 |

The specifications for the Front Emblem-Front Bumper Cover are defined by its role as a premium, durable, and aesthetic branding component.

| Vehicle Application | FAW Jiefang CA3250P66K2L1T1E 6×4 Dump Truck |

| System Group | Front Emblem-Front Bumper Cover |

| Primary Component | ‘Front Emblem’ (5302801-B26) |

| Emblem Substrate | Injection-Molded ABS Plastic |

| Emblem Finish | Multi-Layer Electroplated Chrome (Nickel, Copper, Chromium) |

| Emblem Protection | UV-Resistant Clear Lacquer Topcoat |

| Mounting Hardware | ‘Cross recessed pan head tapping screw and plain washer assembly’ |

| Hardware Part No. | CQ2213595A |

| Hardware Type | Sems Screw (Captive Washer) / Self-Tapping |

| Hardware Quantity | 10 |

| Host Panel | Front Bumper Cover / Front Outer Panel |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.