Welcome to this detailed analysis of the Передняя эмблема-крышка переднего бампера система для FAW Jiefang CA3250P66K2L1T1E 6×4 самосвал. This component group is the “лицо” транспортного средства, a critical element of its brand identity. Это руководство раскроет 2 key parts that create this assembly.

The Передняя эмблема-крышка переднего бампера is the primary identifying feature of the FAW J6P. It is more than just a logo; it is an engineered, multi-piece assembly designed to withstand harsh environments while maintaining a premium, flawless appearance. It is the centerpiece of the cab’s front outer panel.

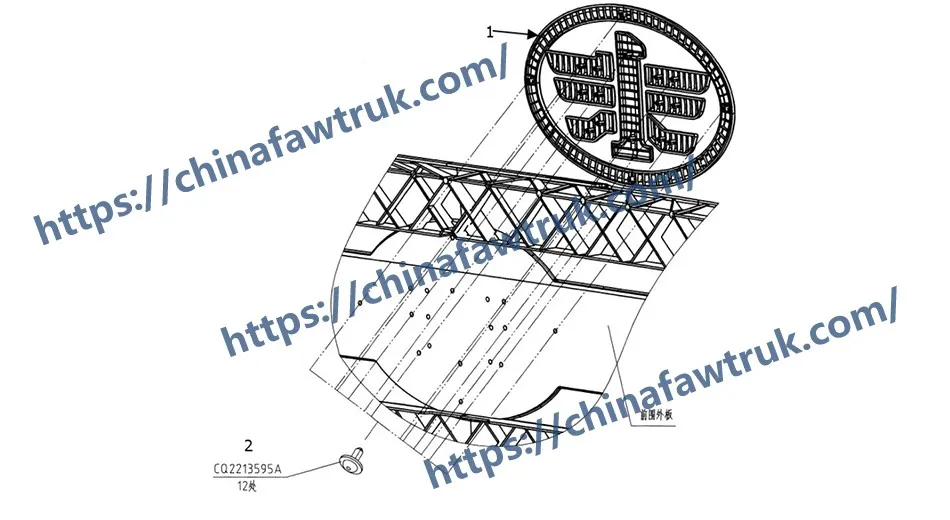

This teardown will analyze the Front Emblem (5302801-B26) and its specialized mounting hardware (CQ2213595A). We will explore the complex manufacturing process of the emblem, from its ABS substrate to its multi-layer chrome plating, and the critical role of its combination-screw fasteners.

For a technician or a fleet owner, а Передняя эмблема-крышка переднего бампера represents the truck’s professionalism. A damaged, peeling, or missing emblem significantly degrades the vehicle’s appearance. Understanding its robust mounting system is key to replacing it correctly, обеспечение безопасного, vibration-free fit that lasts.

Этот компонент является “jewelry” принадлежащий Передняя эмблема-крышка переднего бампера система. It is a complex, multi-layered component engineered for durability and high visual impact.

1. Компонент: ‘Front Emblem’ (5302801-B26) – Кол-во 1

Этот (Отметка 1) is the complete Front Emblem. It is not a simple sticker or a single piece of plastic. It is a sophisticated assembly manufactured to the highest automotive-grade standards.

The Substrate Logic: The foundation of the emblem is an injection-molded substrate made from high-grade, virgin ABS (Акрилонитрил-бутадиен-стирол). This material is chosen for its excellent dimensional stability (it won’t warp in the sun), its superior surface quality, and its ability to perfectly bond with the electroplated layers.

The Electroplating Logic: The brilliant “chrome” finish is not paint. It is a complex, multi-step electroplating process. The ABS substrate is first etched, then dipped in a series of baths to apply a layer of nickel (for adhesion and corrosion resistance), followed by a layer of copper (для гладкого, brilliant surface), and finally the top layer of chromium (for the blue-white shine and surface hardness).

This process is what gives the Передняя эмблема-крышка переднего бампера its true metallic luster and its resistance to stone chips and environmental fallout.

The UV Protection Logic: After electroplating, the entire Front Emblem is coated with a final, transparent automotive-grade lacquer. This clear-coat is the emblem’s primary defense against the elements. It contains high levels of UV inhibitors to prevent the sun from “yellowing” или “fogging” the chrome and plastic substrate over time. It also provides a “wet look” and makes the emblem easier to clean.

The Mounting Boss Logic: The reverse side of the emblem features multiple (в этом случае, 10) molded-in “боссы” или “studs.” These are hollow plastic cylinders that serve two functions: 1. They act as alignment pins, fitting into pre-drilled holes on the bumper cover to ensure the emblem is *perfectly* level and centered. 2. They act as the “женский” threads for the tapping screws (Основной 2).

Логика сервиса: The Front Emblem is a non-serviceable unit. If the chrome is peeling, cracked from a stone chip, or damaged by harsh chemicals, the entire 5302801-B26 part must be replaced. Replacement is a key part of collision repair to restore the vehicle’s “like-new” appearance.

This logic describes the “Front Bumper Cover” сам, что такое “Передняя внешняя панель” (前围外板) referenced in the diagram’s title. This panel is the host for the entire Передняя эмблема-крышка переднего бампера система.

Материальная логика: The bumper cover is a very large, complex molding, typically made of a flexible, impact-resistant polymer like TPO (Thermoplastic Olefin) or a PC/PBT (Polycarbonate/Polybutylene Terephthalate) смешивать. This material is chosen for its “impact memory.”

The Impact Memory Logic: TPO is used on dump trucks because it can deform significantly under a low-speed impact (НАПРИМЕР., bumping a pile of gravel) а затем вернитесь к исходной форме. This flexibility prevents the costly cracking and shattering associated with more rigid plastics, saving the panel from minor impacts.

The “Class-A” Surface Logic: The exterior of the panel is a “Class-A” заканчивать. This is an automotive manufacturing term for a surface that is perfectly smooth, free of any mold marks, sinks, or blemishes, and is ready to accept a high-quality, body-color paint finish. The Передняя эмблема-крышка переднего бампера relies on this perfect surface for its premium fit.

The Precision Logic: This Front Bumper Cover is not just a cosmetic skin. It is an engineered component with hundreds of integrated features. It has molded-in mounting points for the steel reinforcement bar, the headlights, the main grille, и, самое главное, а Front Emblem.

The factory molds 10 precision pilot holes into the panel. These holes perfectly match the 10 mounting bosses on the back of the emblem (Основной 1). This precision-engineering is what guarantees that the emblem is installed perfectly straight, centered, and level on every single truck that leaves the factory.

These are the critical fasteners that physically bond the emblem (Основной 1) to the bumper cover (Основной 2), завершение Передняя эмблема-крышка переднего бампера сборка.

1. Компонент: ‘Саморезный винт с потайной головкой и плоской шайбой в сборе’ (CQ2213595A) – Кол-во 10

Этот (Отметка 2) is the complete set of 10 identical fasteners. The part number designates a “комбинация” или “Sems” винт.

The Combination Logic: Термин “сборка” (Сборка) является ключевым. This is not a separate screw and washer. It is a pre-assembled component where the plain washer is “пленник” under the screw head and cannot fall off.

This design is essential for ease of manufacturing. A technician (or robot) on the assembly line, working from behind the bumper cover, can easily install the screw without having to fumble with a separate, tiny washer. It makes the assembly of the Передняя эмблема-крышка переднего бампера faster and more reliable.

The Load Distribution Logic: The “простая шайба” (Плоская шайба) is a critical engineering component. Its job is to distribute the clamping force of the screw over a wider surface area. Без этой шайбы, the small screw head would concentrate all its force on a narrow ring, which would create a stress point and crack the emblem’s plastic mounting boss. The washer prevents this, обеспечение безопасного, long-lasting fit.

The “Самонарезающий винт” Логика: Это “саморез” (Саморезы). The screws have hardened threads designed to be driven directly into the softer plastic of the emblem’s mounting bosses (Основной 1). They cut their own threads as they are installed, creating an extremely tight, точный, and vibration-resistant connection.

The Quantity Logic: Ten fasteners for a single emblem may seem excessive, but it is intentional. The Front Emblem is large and flat, exposing it to significant wind-buffeting at highway speeds. Using 10 fastening points ensures the emblem is held perfectly flush against the bumper cover, with no “подъем” или “сгибание” at the edges. This prevents wind noise, гремит, and moisture/ice from getting behind the emblem.

Логика сервиса: These fasteners are the key to replacing a damaged Front Emblem. A technician must gain access to the *back* of the Передняя эмблема-крышка переднего бампера to remove these 10 винты. When installing the new emblem, these screws must be tightened carefully by hand. Using a power tool can easily over-torque them, stripping the new plastic bosses and destroying the brand-new emblem.

В следующей таблице представлена полная, подробная разбивка всех 2 типы компонентов, указанные для Передняя эмблема-крышка переднего бампера система на FAW Jiefang CA3250P66K2L1T1E 6×4 самосвал.

| Отметка | Часть №. | Наименование | Количество |

|---|---|---|---|

| 1 | 5302801-B26 | Front Emblem | 1 |

| 2 | CQ2213595A | Самонарезающий винт с крестообразным углублением и плоской головкой в сборе с простой шайбой | 10 |

Технические характеристики Передняя эмблема-крышка переднего бампера are defined by its role as a premium, прочный, and aesthetic branding component.

| Приложение для автомобиля | FAW Цзефан CA3250P66K2L1T1E 6×4 Самосвал |

| Системная группа | Передняя эмблема-крышка переднего бампера |

| Первичный компонент | ‘Front Emblem’ (5302801-B26) |

| Emblem Substrate | Injection-Molded ABS Plastic |

| Emblem Finish | Multi-Layer Electroplated Chrome (Nickel, Copper, Chromium) |

| Emblem Protection | UV-Resistant Clear Lacquer Topcoat |

| Монтажное оборудование | ‘Саморезный винт с потайной головкой и плоской шайбой в сборе’ |

| Hardware Part No. | CQ2213595A |

| Hardware Type | Sems Screw (Captive Washer) / Саморезы |

| Количество оборудования | 10 |

| Host Panel | Front Bumper Cover / Передняя внешняя панель |

Запчасти ФАВ, включая блок цилиндров в сборе, тщательно упакованы, чтобы обеспечить безопасную доставку. Каждый компонент закреплен защитными материалами для предотвращения повреждений при транспортировке.. Логистическая сеть гарантирует своевременную доставку по всему миру., поддержка эффективных операций по техническому обслуживанию. Ниже приведено изображение, иллюстрирующее стандартную упаковку запчастей для грузовиков FAW., демонстрация внимания к деталям в обращении и хранении.

Такой подход к упаковке сводит к минимуму риск коррозии или ударного повреждения., обеспечение доставки таких деталей, как блок цилиндров FAW в сборе, в идеальном состоянии.. Клиенты могут положиться на логистику FAW для обеспечения стабильного качества и надежности..