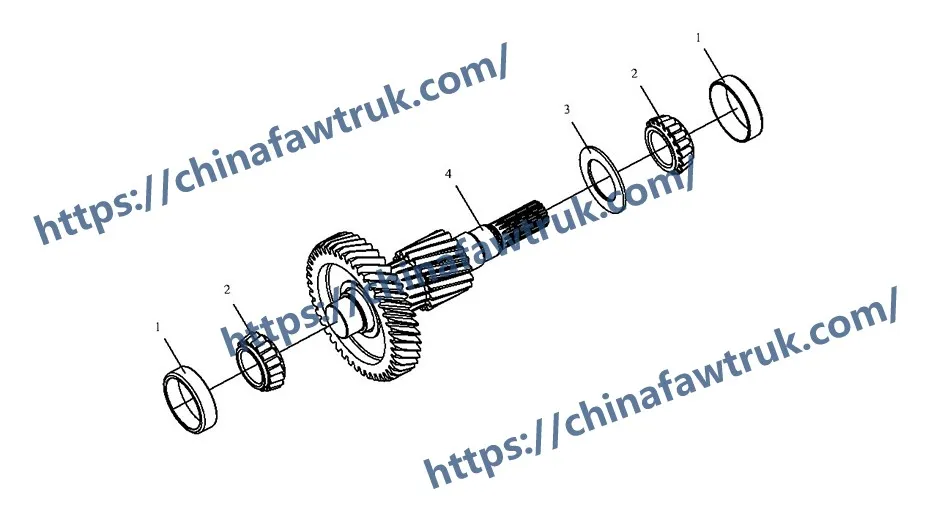

Welcome to this in-depth deconstruction of the Sub-Box Right Lower Centre Shaft, a foundational component for the CA10TA160M 10-speed transmission in the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck. This guide is for technicians, analyzing the 4 critical parts that form the complete Sub-Box Right Lower Centre Shaft assembly, which is essential for the auxiliary box’s “range-split” function.

The Sub-Box Right Lower Centre Shaft is a high-torque countershaft for the auxiliary (Hi/Lo) gearbox. Its logic is to receive power from the main box and transmit it to the final output gears. This specific component also includes the provision “with PTO,” making it a critical link for powering auxiliary equipment like hydraulic pumps.

This component is the literal foundation of the Sub-Box Right Lower Centre Shaft assembly. It is a single, integrated part that provides the “drive” for the auxiliary gearbox and, crucially, the Power Take-Off.

1. Component: ‘Welded intermediate shaft assy – auxiliary box’ (1701515AA1K)

This (Comp 4) is the core component. The name ‘Welded intermediate shaft assy’ (焊接中间轴总成) confirms it is a non-serviceable assembly. This is the Sub-Box Right Lower Centre Shaft itself, and its gears are permanently welded to the shaft for maximum strength.

The Welded Logic is a design choice for extreme strength. Instead of using splines or keys that can shear under the immense, multiplied torque of the low-range gears, the manufacturer has welded the gear(s) directly to the shaft. This creates a single, solid piece of steel that can withstand the brutal forces of a fully-loaded dump truck. This is a hallmark of the Sub-Box Right Lower Centre Shaft.

The Countershaft Logic is its function. This Sub-Box Right Lower Centre Shaft acts as the “countershaft” or “layshaft” for the auxiliary gearbox. It is part of a “twin-countershaft” system (along with the “Left Upper” shaft), which splits the power from the main box. This load-sharing is what gives the transmission its high torque rating.

The PTO Logic is the distinguishing feature of this specific Sub-Box Right Lower Centre Shaft. The note “(带取力器)” means “with Power Take-Off.” This implies that one of the welded gears on this shaft (Comp 4) is the primary “drive gear” for the truck’s PTO.

This is critical: when the driver engages the PTO to run the hydraulic dump body, the PTO’s idler gear meshes with this specific gear on the Sub-Box Right Lower Centre Shaft. This allows the truck to be stationary (in neutral) while the clutch is engaged, spinning this shaft to power the hydraulic pump. The strength of this assembly is paramount.

This group represents the complete bearing assembly that supports the Sub-Box Right Lower Centre Shaft. A high-load shaft like this, especially one driving a PTO, requires a bearing system that can handle massive, multi-directional forces.

1. Component: ‘Tapered roller bearing outer ring’ (306/42-1-1) – Qty 2

This (Comp 1) is the “cup” or “outer race” of the bearing. Two of these are used, one for the front bearing and one for the rear. This cup is precision-machined and is pressed *into the bore* of the auxiliary gearbox housing, where it remains stationary. This is a high-wear part in the Sub-Box Right Lower Centre Shaft system.

2. Component: ‘Tapered roller bearing inner ring’ (306/42-1-2) – Qty 2

This (Comp 2) is the “cone” or “inner ring” of the bearing, which includes the tapered rollers in their cage. This cone is pressed *onto the journals* (ends) of the Sub-Box Right Lower Centre Shaft (Comp 4) and spins with it.

The Tapered Roller Logic is the most important concept for this Sub-Box Right Lower Centre Shaft. Unlike a simple ball bearing, a tapered roller bearing is specifically designed to handle *both* massive radial loads (the “pushing” force from the gear mesh) and massive *axial* loads (the “thrust” force generated by helical-cut gears) *at the same time*.

The Opposed Mounting Logic is how they work. The two tapered bearings (Comp 1 + Comp 2) are mounted in “opposition” at the front and rear of the Sub-Box Right Lower Centre Shaft. This creates an extremely rigid assembly that can support the shaft against thrust forces in *both* directions (fore and aft), ensuring perfect gear mesh alignment under all load conditions, which is critical when the PTO is engaged.

The Service Logic is why they are listed as separate inner and outer rings. They are a “matched set” and must be replaced as one. A technician presses the outer rings into the housing and the inner rings onto the Sub-Box Right Lower Centre Shaft before final assembly.

This final component is one of the most critical parts of the entire Sub-Box Right Lower Centre Shaft assembly. It is a single washer that ensures the longevity of the expensive bearings and shaft.

1. Component: ‘Positioning washer’ (1701518-A7G)

This (Comp 3) is the ‘Positioning washer’. In a tapered roller bearing application, this is not a simple washer; it is a “shim” or “gasket-shim.” Its thickness is precisely controlled, and its function is to set the “bearing pre-load.”

The Pre-load Logic is a high-precision assembly task. Tapered roller bearings cannot be “loose” (with end play), nor can they be “too tight.” They require a specific, slight amount of “squeeze” or “pre-load” to function correctly and maximize their lifespan.

During assembly of the Sub-Box Right Lower Centre Shaft, a technician installs the components and measures the “end play” (the in-and-out movement) with a dial indicator. They then select a ‘Positioning washer’ (Comp 3) of the *exact* thickness required to eliminate that end play and add the correct, specified pre-load (e.g., 0.05mm).

This washer is often placed between a bearing’s outer ring (Comp 1) and the housing or bearing cover. Its thickness is the only thing that guarantees the correct pre-load for the bearings supporting the Sub-Box Right Lower Centre Shaft.

A Sub-Box Right Lower Centre Shaft with incorrect pre-load (e.g., a shim that is too thick or too thin) will suffer catastrophic bearing failure in a very short time. Too tight, and the bearings will overheat and seize. Too loose, and the shaft will “walk” axially, causing the gear teeth to misalign and destroying both the shaft (Comp 4) and the gears it meshes with. Therefore, this ‘Positioning washer’ (Comp 3) is a critical, non-negotiable component for a successful gearbox rebuild.

The following table provides the complete, detailed breakdown of all 4 component types in the Sub-Box Right Lower Centre Shaft assembly for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 306/42-1-1 | Tapered roller bearing outer ring | 2 |

| 2 | 306/42-1-2 | Tapered roller bearing inner ring | 2 |

| 3 | 1701518-A7G | Positioning washer | 1 |

| 4 | 1701515AA1K | Welded intermediate shaft assy – auxiliary box (with PTO) | 1 |

The specifications for the Sub-Box Right Lower Centre Shaft are defined by its role as a high-load, high-precision countershaft for the auxiliary gearbox, specifically featuring a PTO drive.

| Vehicle Application | FAW Jiefang CA3250P66K2L1T1E 6×4 Dump Truck |

| System Group | Sub-Box Right Lower Centre Shaft |

| Associated Gearbox | CA10TA160M (Auxiliary Box Section) |

| Primary Logic | Auxiliary Countershaft / Layshaft |

| Core Component | ‘Welded intermediate shaft assy – auxiliary box’ (1701515AA1K) |

| Shaft Construction | Welded (Gears permanently attached to shaft) |

| Key Feature | Includes Power Take-Off (PTO) Drive Gear |

| Bearing Type | Tapered Roller Bearing (Set of 2) |

| Bearing Components | ‘Outer ring’ (306/42-1-1) & ‘Inner ring’ (306/42-1-2) |

| Pre-load/Positioning | ‘Positioning washer’ (1701518-A7G) |

| Total Component Types | 4 |

| Associated System | Auxiliary Box (Hi/Lo Range) & PTO Assembly |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.