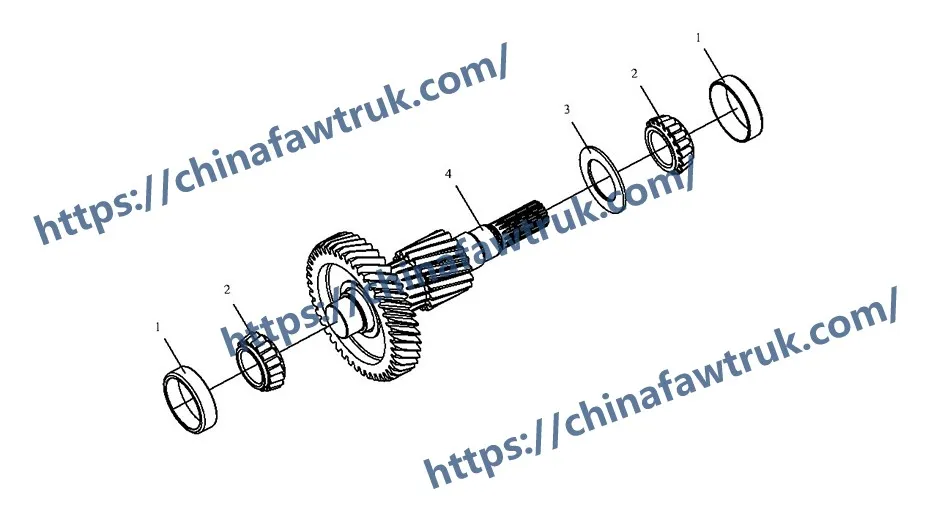

Bem-vindo a esta desconstrução profunda do Eixo central inferior direito da sub-caixa, a foundational component for the CA10TA160M 10-speed transmission in the FAW Jiefang CA3250P66K2L1T1E 6×4 caminhão despejando. Este guia é para técnicos, analisando o 4 critical parts that form the complete Eixo central inferior direito da sub-caixa conjunto, which is essential for the auxiliary box’s “range-split” função.

O Eixo central inferior direito da sub-caixa is a high-torque countershaft for the auxiliary (Hi/Lo) caixa de câmbio. Its logic is to receive power from the main box and transmit it to the final output gears. This specific component also includes the provision “with PTO,” making it a critical link for powering auxiliary equipment like hydraulic pumps.

This component is the literal foundation of the Eixo central inferior direito da sub-caixa conjunto. É um único, integrated part that provides the “dirigir” for the auxiliary gearbox and, crucialmente, the Power Take-Off.

1. Componente: ‘Welded intermediate shaft assy – caixa auxiliar’ (1701515AA1K)

Esse (Comp. 4) is the core component. The name ‘Welded intermediate shaft assy’ (焊接中间轴总成) confirms it is a non-serviceable assembly. Este é o Eixo central inferior direito da sub-caixa em si, and its gears are permanently welded to the shaft for maximum strength.

O Welded Logic is a design choice for extreme strength. Instead of using splines or keys that can shear under the immense, multiplied torque of the low-range gears, the manufacturer has welded the gear(é) directly to the shaft. This creates a single, solid piece of steel that can withstand the brutal forces of a fully-loaded dump truck. This is a hallmark of the Eixo central inferior direito da sub-caixa.

O Countershaft Logic é a sua função. Esse Eixo central inferior direito da sub-caixa atua como o “countershaft” ou “layshaft” for the auxiliary gearbox. It is part of a “contraeixo duplo” sistema (juntamente com o “Esquerda Superior” haste), which splits the power from the main box. This load-sharing is what gives the transmission its high torque rating.

O PTO Logic is the distinguishing feature of this specific Eixo central inferior direito da sub-caixa. A nota “(带取力器)” means “with Power Take-Off.” This implies that one of the welded gears on this shaft (Comp. 4) é o principal “drive gear” for the truck’s PTO.

Isto é crítico: when the driver engages the PTO to run the hydraulic dump body, the PTO’s idler gear meshes with this specific gear on the Eixo central inferior direito da sub-caixa. This allows the truck to be stationary (in neutral) while the clutch is engaged, spinning this shaft to power the hydraulic pump. The strength of this assembly is paramount.

This group represents the complete bearing assembly that supports the Eixo central inferior direito da sub-caixa. A high-load shaft like this, especially one driving a PTO, requires a bearing system that can handle massive, multi-directional forces.

1. Componente: ‘Tapered roller bearing outer ring’ (306/42-1-1) – Quantidade 2

Esse (Comp. 1) é o “xícara” ou “outer race” of the bearing. Two of these are used, one for the front bearing and one for the rear. This cup is precision-machined and is pressed *into the bore* of the auxiliary gearbox housing, where it remains stationary. This is a high-wear part in the Eixo central inferior direito da sub-caixa sistema.

2. Componente: ‘Tapered roller bearing inner ring’ (306/42-1-2) – Quantidade 2

Esse (Comp. 2) é o “cone” ou “inner ring” of the bearing, which includes the tapered rollers in their cage. This cone is pressed *onto the journals* (termina) do Eixo central inferior direito da sub-caixa (Comp. 4) and spins with it.

O Lógica de rolo cônico is the most important concept for this Eixo central inferior direito da sub-caixa. Unlike a simple ball bearing, a tapered roller bearing is specifically designed to handle *both* massive radial loads (o “empurrando” force from the gear mesh) and massive *axial* loads (o “impulso” force generated by helical-cut gears) *at the same time*.

O Opposed Mounting Logic is how they work. The two tapered bearings (Comp. 1 + Comp. 2) are mounted in “opposition” at the front and rear of the Eixo central inferior direito da sub-caixa. This creates an extremely rigid assembly that can support the shaft against thrust forces in *both* directions (fore and aft), ensuring perfect gear mesh alignment under all load conditions, which is critical when the PTO is engaged.

O Lógica de serviço is why they are listed as separate inner and outer rings. Eles são um “matched set” and must be replaced as one. A technician presses the outer rings into the housing and the inner rings onto the Eixo central inferior direito da sub-caixa before final assembly.

This final component is one of the most critical parts of the entire Eixo central inferior direito da sub-caixa conjunto. It is a single washer that ensures the longevity of the expensive bearings and shaft.

1. Componente: ‘Arruela de posicionamento’ (1701518-A7G)

Esse (Comp. 3) is the ‘Positioning washer’. In a tapered roller bearing application, this is not a simple washer; é um “shim” ou “gasket-shim.” Its thickness is precisely controlled, and its function is to set the “bearing pre-load.”

O Pre-load Logic is a high-precision assembly task. Tapered roller bearings cannot be “solto” (with end play), nor can they be “too tight.” They require a specific, slight amount of “espremer” ou “pré-carregamento” to function correctly and maximize their lifespan.

During assembly of the Eixo central inferior direito da sub-caixa, a technician installs the components and measures the “fim do jogo” (the in-and-out movement) with a dial indicator. They then select a ‘Positioning washer’ (Comp. 3) of the *exact* thickness required to eliminate that end play and add the correct, specified pre-load (Por exemplo, 0.05milímetros).

This washer is often placed between a bearing’s outer ring (Comp. 1) and the housing or bearing cover. Its thickness is the only thing that guarantees the correct pre-load for the bearings supporting the Eixo central inferior direito da sub-caixa.

A Eixo central inferior direito da sub-caixa with incorrect pre-load (Por exemplo, a shim that is too thick or too thin) will suffer catastrophic bearing failure in a very short time. Too tight, and the bearings will overheat and seize. Too loose, and the shaft will “andar” axialmente, causing the gear teeth to misalign and destroying both the shaft (Comp. 4) and the gears it meshes with. Portanto, this ‘Positioning washer’ (Comp. 3) é uma crítica, non-negotiable component for a successful gearbox rebuild.

A tabela a seguir fornece o completo, detalhamento de todos 4 tipos de componentes no Eixo central inferior direito da sub-caixa montagem para o FAW Jiefang CA3250P66K2L1T1E 6×4 caminhão despejando.

| Marca | Parte não. | Nome da peça | Quantidade |

|---|---|---|---|

| 1 | 306/42-1-1 | Tapered roller bearing outer ring | 2 |

| 2 | 306/42-1-2 | Tapered roller bearing inner ring | 2 |

| 3 | 1701518-A7G | Arruela de posicionamento | 1 |

| 4 | 1701515AA1K | Welded intermediate shaft assy – caixa auxiliar (with PTO) | 1 |

As especificações para o Eixo central inferior direito da sub-caixa are defined by its role as a high-load, high-precision countershaft for the auxiliary gearbox, specifically featuring a PTO drive.

| Aplicação em veículos | FAW Jiefang CA3250P66K2L1T1E 6×4 Caminhão basculante |

| Grupo de sistemas | Eixo central inferior direito da sub-caixa |

| Caixa de velocidades associada | CA10TA160M (Auxiliary Box Section) |

| Lógica Primária | Auxiliary Countershaft / Layshaft |

| Componente principal | ‘Welded intermediate shaft assy – caixa auxiliar’ (1701515AA1K) |

| Shaft Construction | Soldado (Gears permanently attached to shaft) |

| Recurso -chave | Includes Power Take-Off (PTO) Engrenagem de acionamento |

| Tipo de rolamento | Rolamento de rolo cônico (Conjunto de 2) |

| Componentes de rolamento | ‘Outer ring’ (306/42-1-1) & ‘Inner ring’ (306/42-1-2) |

| Pre-load/Positioning | ‘Arruela de posicionamento’ (1701518-A7G) |

| Total de tipos de componentes | 4 |

| Sistema Associado | Caixa Auxiliar (Hi/Lo Range) & Montagem da tomada de força |

Peças FAW, incluindo o conjunto do bloco de cilindros, são embalados com cuidado para garantir uma entrega segura. Cada componente é protegido por materiais de proteção para evitar danos durante o transporte. A rede logística garante envios pontuais em todo o mundo, apoiando operações de manutenção eficientes. Abaixo está uma imagem ilustrando a embalagem padrão para peças de caminhão FAW, mostrando a atenção aos detalhes no manuseio e armazenamento.

Esta abordagem de embalagem minimiza o risco de corrosão ou danos por impacto, garantindo que peças como o conjunto do bloco de cilindros FAW cheguem em perfeitas condições. Os clientes podem confiar na logística da FAW para obter qualidade e confiabilidade consistentes.