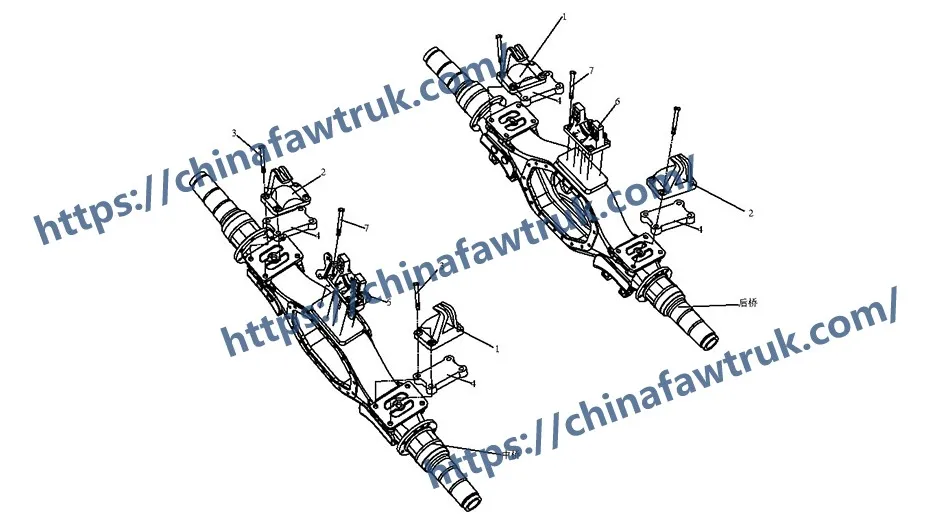

This is the technical deconstruction of the Rear Axle Bolted Suspension Bracket system for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck. This guide details the 7 serviceable component types that form this critical chassis-to-axle link, focusing on the elements that support the rear axle.

The Rear Axle Bolted Suspension Bracket is a complete system of heavy-gauge steel brackets, shims, and high-tensile fasteners that secures the tandem-axle suspension. This bolted assembly is designed for serviceability, allowing technicians to replace individual brackets that may wear or be damaged. This deconstruction will analyze the main spring trunnion brackets, the specific rear axle reaction rod brackets, and the fastener systems used to maintain the vehicle’s structural integrity. Understanding this Rear Axle Bolted Suspension Bracket is key to tandem-axle maintenance.

This group represents the foundation of the Rear Axle Bolted Suspension Bracket system. These are the primary components that transfer the vehicle’s load from the frame to the leaf springs shared by the tandem axles.

1. Component: ‘Rear leaf spring bracket assy’ (2912445-65B & 2912450-65B) – Qty 2 each

These (Comp 1 & 2) are the main, mirrored assemblies for the left and right sides of the frame. In a tandem setup, this is often called the trunnion bracket. They are massive, fabricated steel components that house the leaf spring’s pivot point. The Bolted Logic is key: these brackets are bolted *directly* to the truck’s frame rail, allowing for replacement in case of stress fracturing, a key feature of the Rear Axle Bolted Suspension Bracket.

2. Component: ‘Hexagon head bolt with pin hole’ (CQ1512095T) – Qty 16

This (Comp 3) is a specialized, high-tensile fastener. The pin hole feature allows for a cotter pin or locking wire, providing a redundant safety mechanism. This Fastener Logic ensures that even under extreme vibration, the main nuts cannot back off. These 16 bolts secure the main trunnion brackets (Comp 1 & 2) to the frame, making them critical to the Rear Axle Bolted Suspension Bracket‘s safety.

This component group ensures the entire tandem bracket system is perfectly aligned on the frame. Misalignment of the Rear Axle Bolted Suspension Bracket assembly can lead to poor handling, severe tire wear, and ‘dog tracking’.

1. Component: ‘Shim and positioning pin assy – rear leaf spring bracket’ (2912405-65B) – Qty 4

This (Comp 4) is a precision alignment assembly. The Positioning Pin Logic is simple but effective: pins on this plate lock into pre-drilled holes in the truck frame, acting as dowels. The main spring brackets (Comp 1 & 2) are then located against these pins *before* the bolts (Comp 3) are tightened.

The ‘shim’ aspect of this assembly is also critical. It allows for fine-tuning the bracket’s position to compensate for minor variations in the frame. This part makes the installation of a new Rear Axle Bolted Suspension Bracket component both precise and repeatable, which is essential for correct tandem-axle geometry.

This group of components works with the Rear Axle Bolted Suspension Bracket system to manage axle torque. The reaction rods (or ‘torque rods’) prevent the axles from rotating during acceleration and braking. These brackets are the frame-side anchor points for those rods.

1. Component: ‘Reaction rod rear upper bracket assy’ (2919220-65B) – Qty 1

This (Comp 6) is the key component for the *rear* axle within this assembly. It is a complete bracket assembly (‘2919212-517’) designed specifically to anchor the *rear* axle’s upper reaction rod. It also uses an ‘Elastic dowel pin’ (‘2919201-A2E’) for a tight, vibration-dampening fit. This is a core part of the Rear Axle Bolted Suspension Bracket‘s function.

2. Component: ‘Reaction rod upper bracket on mid-bridge assy’ (2919210-65B) – Qty 1

This (Comp 5), listed in the same component diagram, is the corresponding bracket for the *middle* axle. It includes its specific bracket (‘2919211-65B’) and pins (‘2919201-A2E’, ‘2919202-A2E’). It is part of the overall tandem system and shares the same mounting logic as the Rear Axle Bolted Suspension Bracket.

3. Component: ‘Bolt’ (CQ1502085T) – Qty 16

This (Comp 7) is another set of 16 high-tensile bolts. These fasteners are used to secure the reaction rod brackets (Comp 5 & 6) to the frame crossmembers. The use of 32 total main bolts (Comp 3 & 7) for this entire Rear Axle Bolted Suspension Bracket system highlights the immense forces it is designed to handle.

The following table provides the complete, detailed breakdown of all 7 component types in the Rear Axle Bolted Suspension Bracket assembly for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck. This list covers the tandem-axle bracket system and is essential for ordering the correct hardware. This Rear Axle Bolted Suspension Bracket is a fully serviceable assembly.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 2912445-65B / 2912450-65B | Rear leaf spring bracket assy – mid left/right | 2 |

| 2 | 2912450-65B / 2912445-65B | Rear leaf spring bracket assy – mid right/left | 2 |

| 3 | CQ1512095T | Hexagon head bolt with pin hole | 16 |

| 4 | 2912405-65B | Shim and positioning pin assy – rear leaf spring bracket | 4 |

| 5 | 2919210-65B | Reaction rod upper bracket on mid-bridge assy | 1 |

| 6 | 2919220-65B | Reaction rod rear upper bracket assy | 1 |

| 7 | CQ1502085T | Bolt | 16 |

The specifications for this Rear Axle Bolted Suspension Bracket are defined by its function as a serviceable, high-strength chassis mounting system for the tandem-axle suspension. Proper torque on all fasteners is critical for this Rear Axle Bolted Suspension Bracket.

| Vehicle Application | FAW Jiefang CA3250P66K2L1T1E 6×4 Dump Truck |

| System Group | Rear Axle Bolted Suspension Bracket |

| Primary Logic | Secures rear leaf springs and reaction rods to the frame |

| Main Components | ‘Rear leaf spring bracket assy’ (Trunnion) |

| Key Feature | Bolted, serviceable assembly (not welded) |

| Alignment System | ‘Shim and positioning pin assy’ (2912405-65B) |

| Torque Control Point (Rear) | ‘Reaction rod rear upper bracket assy’ (2919220-65B) |

| Fastener Type (Main) | ‘Hexagon head bolt with pin hole’ (CQ1512095T) |

| Total Component Types | 7 |

| Associated System | Chassis / Rear Suspension (Tandem Axle). This Rear Axle Bolted Suspension Bracket is a core component. |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.