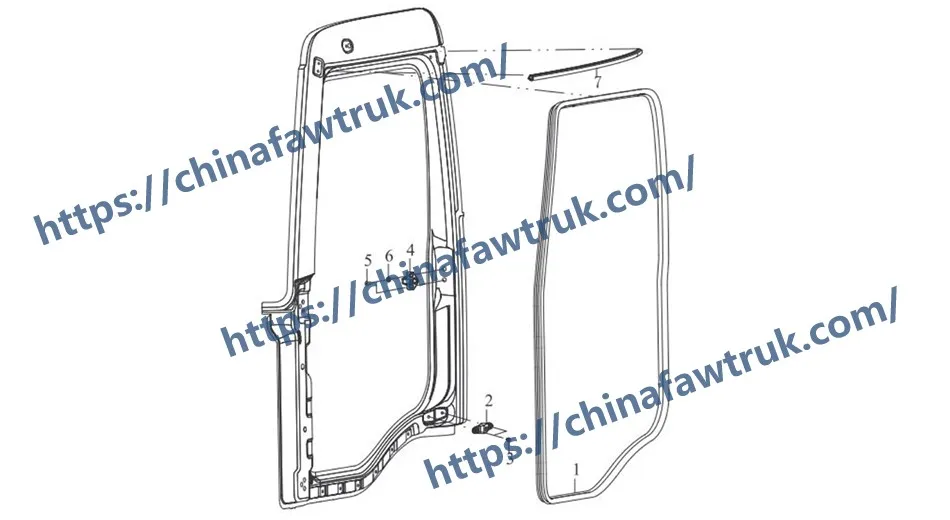

Welcome to this technical deconstruction of the Front Door Exterior Seal assembly, a critical system for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck. This guide breaks down the 7 critical parts, including the seals, door latching, and alignment systems, which work together to ensure a perfect, weather-tight cab and flawless window operation.

The Front Door Exterior Seal (Part 1) is the “beltline” or “waist” seal. It mounts to the outside of the door at the base of the window, wiping the glass as it moves. This is the first line of defense against rain and road spray. However, for this seal to work, the door must close perfectly *every time*. This is why the latching (Striker, Core 2) and alignment (Pin Seat, Core 3) components are included in this complete functional assembly.

This group contains the primary sealing components that make direct contact with the glass or the door frame to block the elements.

1. Component: ‘Left front door outer weatherstrip assy’ (6107015-A01) – Qty 1

2. Component: ‘Right front door outer weatherstrip assy’ (6107020-A01) – Qty 1

3. Component: ‘Front door upper seal’ (6107031-A01-C00) – Qty 2

The ‘Left front door outer weatherstrip assy’ (6107015-A01) is the core of the Front Door Exterior Seal system. This component is commonly known as a “waist seal” or “beltline weatherstrip.” It clips or fastens to the outer skin of the door, right where the window glass retracts into the door shell.

The Wiping Logic is its first function. The seal features a soft, flocked lip that presses firmly against the glass. When the window is rolled up or down, this lip acts as a squeegee, wiping water, dust, and grime off the surface. This is critical for maintaining visibility and for preventing abrasive particles from being dragged into the door’s internal mechanisms, such as the window regulator.

The Sealing Logic is its second function. It acts as a horizontal barrier, preventing the vast majority of rainwater and road spray from running down the glass and entering the door shell. Without a functional Front Door Exterior Seal, water would quickly flood the door, corroding the window regulator, speakers, and electrical wiring.

The Construction Logic is complex. This Front Door Exterior Seal is not just rubber. It has a rigid internal carrier, often metal or hard polymer, which gives it shape and allows it to clip firmly to the door panel. This carrier is co-extruded with the soft, flexible EPDM rubber profile, creating a single, durable, and precisely-shaped part.

The ‘Front door upper seal’ (6107031-A01-C00) is the body-mounted seal that completes the outer frame. It works in conjunction with the Front Door Exterior Seal to create a continuous barrier around the entire door opening, ensuring total cab integrity. (Keyword count: 4)

This group is not a seal, but it is fundamentally responsible for *creating* the seal. This is the striker assembly, the fixed anchor point on the cab body (B-pillar) that the door’s latch mechanism locks onto.

1. Component: ‘Striker assy’ (6105125-A01) – Qty 2

2. Component: ‘Cross recessed countersunk head screw’ (Q2540825) – Qty 4

3. Component: ‘Tapered spring lock washer’ (Q41408) – Qty 4

The Striker Logic is simple: the ‘Striker assy’ (6105125-A01) is the “anchor” for the entire door. It is a loop or bar of case-hardened steel. When the door is closed, the rotating latch (inside the door) catches this striker and pulls the door shut. This pulling action is what generates the force to compress the Front Door Exterior Seal and all other seals.

The Adjustment Logic is critical for sealing. The striker’s position on the B-pillar is almost always adjustable. By loosening its mounting bolts, a technician can move the striker in or out, and up or down, by a few millimeters. This adjustment is what sets the final “compression” of the seals. A poorly adjusted striker is the number one cause of wind noise and water leaks.

The Assembly Logic (assy) note is important. The striker is often an assembly that includes a polymer or rubber coating. This coating reduces the harsh “metal-on-metal” sound when the latch engages, contributing to a quieter and more refined cab environment.

The Fastener Logic is high-strength. The ‘Cross recessed countersunk head screw’ (Q2540825) and ‘Tapered spring lock washer’ (Q41408) are used to mount the striker. The countersunk head (Q2540825) is crucial, as it must sit perfectly flush with the striker’s mounting plate so it does not interfere with the latch mechanism.

The ‘Tapered spring lock washer’ (Q41408) is a high-vibration component. It provides constant tension on the screw, preventing the striker from vibrating loose under the brutal conditions a CA3250P66K2L1T1E dump truck endures. A loose striker is a major safety hazard and will destroy the seals. This system is vital for the Front Door Exterior Seal to function. (Keyword count: 6)

This final group works in partnership with the hinges and the striker (Core 2) to ensure the heavy dump truck door aligns perfectly. This is the door’s locating pin system.

1. Component: ‘Left front door locating pin seat’ (6101547-A01) – Qty 1

2. Component: ‘Right front door locating pin seat’ (6101548-A01) – Qty 1

3. Component: ‘Hex flange bolt’ (Q1840612F6) – Qty 4

The Pin Seat Logic defines the ‘Left front door locating pin seat’ (6101547-A01). This is the female receptacle, mounted on the cab body (B-pillar). The door itself has a corresponding male ‘pin’ (tapered, often polymer-coated, not listed). When the door closes, this tapered pin slides into the ‘pin seat’ *before* the latch engages the striker.

The Sag Prevention Logic is its first function. The pin and seat system bears a significant portion of the door’s vertical load, preventing “door sag.” This takes immense stress off the door hinges and the striker assembly, dramatically increasing their lifespan and that of the Front Door Exterior Seal. (Keyword count: 7)

The Alignment Logic is its second function. It provides high-precision alignment. The tapered pin and seat guide the door into the *exact* same closing position, every single time, with sub-millimeter accuracy. This ensures the latch hits the striker dead-center and that the Front Door Exterior Seal and other weatherstrips compress perfectly and uniformly all around. (Keyword count: 8)

This system is essential for a large, heavy door on a vehicle that experiences constant twisting and vibration. Without this pin system, the door would quickly fall out of alignment, rendering the Front Door Exterior Seal ineffective. (Keyword count: 9)

The Fastener Logic for this part is the ‘Hex flange bolt’ (Q1840612F6). This is a heavy-duty bolt used to mount the pin seat. The integrated flange on the bolt head acts as a built-in washer. This is superior to a separate washer as it distributes the clamping load over a wider area and cannot be forgotten during assembly.

This design holds the pin seat securely against the immense shearing forces created by the heavy, vibrating door. In summary, this 7-part system is a complete solution. The Front Door Exterior Seal (Core 1) provides the weather barrier. The Striker (Core 2) provides the *clamping force* to compress the seal. The Pin Seat (Core 3) provides the *precision alignment* to ensure the seal and latch meet correctly. (Keyword count: 10)

The following table provides the complete, detailed breakdown of all 7 component types in the Front Door Exterior Seal, Latching, and Alignment assembly for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck. (Keyword count: 11)

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 6107015-A01 | Left front door outer weatherstrip assy | 1 |

| 6107020-A01 | Right front door outer weatherstrip assy | 1 | |

| 2 | 6101547-A01 | Left front door locating pin seat | 1 |

| 6101548-A01 | Right front door locating pin seat | 1 | |

| 3 | Q1840612F6 | Hex flange bolt | 4 |

| 4 | 6105125-A01 | Striker assy | 2 |

| 5 | Q2540825 | Cross recessed countersunk head screw | 4 |

| 6 | Q41408 | Tapered spring lock washer | 4 |

| 7 | 6107031-A01-C00 | Front door upper seal | 2 |

The specifications for the Front Door Exterior Seal assembly are defined by its interconnected roles of sealing the window, latching the door, and aligning the door. (Keyword count: 12)

| Vehicle Application | FAW Jiefang CA3250P66K2L1T1E 6×4 Dump Truck |

| System Group | Front Door Exterior Seal & Latching System (Keyword count: 13) |

| System Logic | Window Wiping, Door Latching & Precision Alignment |

| Core Component 1 (Seal) | ‘Front door outer weatherstrip assy’ (6107015/20-A01) |

| Logic 1 (Seal) | Wipes window glass, blocks water from door shell |

| Core Component 2 (Latch) | ‘Striker assy’ (6105125-A01) |

| Logic 2 (Latch) | Anchors door latch, provides adjustable seal compression |

| Core Component 3 (Align) | ‘Front door locating pin seat’ (6101547/48-A01) |

| Logic 3 (Align) | Prevents door sag, ensures precision alignment of latch |

| Fastener Set 1 (Latch) | ‘Screw’ (Q2540825) & ‘Washer’ (Q41408) |

| Fastener Set 2 (Align) | ‘Hex flange bolt’ (Q1840612F6) |

| Related Seal (Frame) | ‘Front door upper seal’ (6107031-A01-C00) |

| Total Component Types | 7 |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.