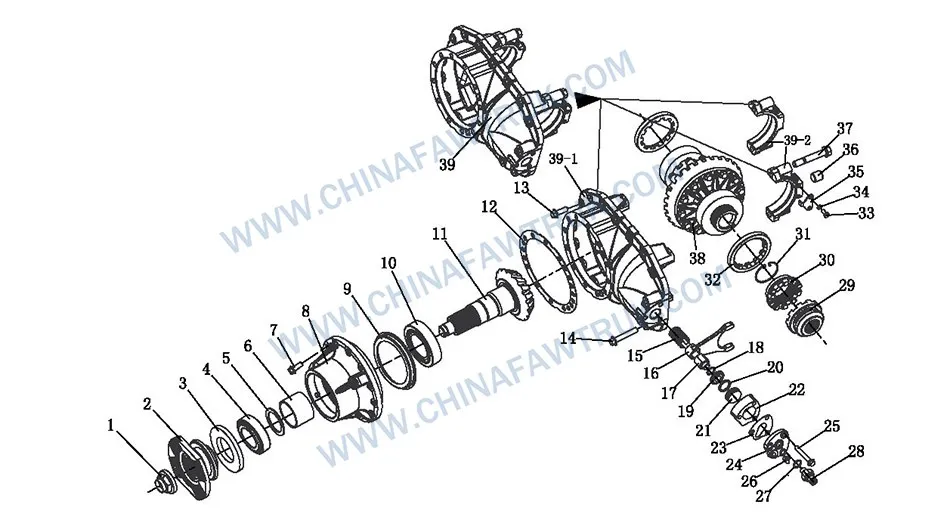

Boîte de réduction de l'essieu avant russe FAW: Ingénierie 39 Composants stratégiques pour Ultimate 6×6 Traction

Le Boîte de réduction de l'essieu avant russe FAW L'assemblage représente le fer de lance de la capacité de transmission intégrale du camion-benne CA3250P66K24L1TE5Z.. Situé dans le carter de l'essieu avant, cet ensemble logique complexe gère la réduction de vitesse primaire et le mécanisme critique de verrouillage du différentiel entre les roues. Dans la toundra gelée impitoyable de la Fédération de Russie, où la traction détermine la survie, cette boîte de vitesses doit convertir la rotation de l'arbre de transmission à grande vitesse en une rotation massive, couple de barattage au sol. Ce guide complet déconstruit le 39 composants essentiels, de l'engrenage conique d'entraînement usiné avec précision aux actionneurs pneumatiques de blocage de différentiel, s'assurer que le Boîte de réduction de l'essieu avant russe FAW offre des performances inflexibles à des températures aussi basses que -40°C.

Boîte de réduction de l'essieu avant russe FAW

Précision d'entrée: Brides et joints d'huile

Le point d’entrée du pouvoir dans le Boîte de réduction de l'essieu avant russe FAW est le Assemblage de bride (Partie no. 2502065-557). Ce composant forgé robuste relie l'arbre de transmission avant au pignon d'entrée.. Il est sécurisé par le couple élevé Écran de verrouillage – 2ème bride d'arbre (Partie no. 1701471-11), qui applique la précharge nécessaire à la pile de roulements. Dans le Boîte de réduction de l'essieu avant russe FAW, la rigidité de cette connexion est primordiale. Tout jeu au niveau de la bride se traduit par un jeu dans les engrenages, ce qui peut briser les dents sous les chocs de la conduite tout-terrain.

Sceller cette interface rotative contre les durs éléments russes est la tâche du Ensemble de joint d'huile pour engrenage conique d'entraînement (Partie no. 2302055-820-C00). Ce n'est pas un sceau standard; c'est un multi-lèvres, joint de type cassette conçu pour fonctionner dans un environnement de boue abrasive, glace, et sels de voirie chimiques. La composition matérielle du joint est critique pour le Boîte de réduction de l'essieu avant russe FAW. Il utilise des fluoroélastomères avancés qui conservent leur flexibilité à -40°C, s'assurer que l'huile pour engrenages reste à l'intérieur du boîtier et que les contaminants restent à l'extérieur.

En outre, le Siège de roulement – 1st Engrenage conique d'entraînement de l'essieu avant (Partie no. 2302049-820) fournit le boîtier structurel pour l'ensemble d'entrée. Ce moulage est usiné avec précision pour maintenir les bagues extérieures des roulements à rouleaux coniques. Il dispose d'un intégré Bouclier d'huile – Siège de roulement d'engrenage conique d'entraînement (Partie no. 2402048-A0E) pour gérer le flux d'huile. Ce bouclier empêche l'huile barattée par la couronne dentée d'inonder le roulement avant., s'assurer que le Boîte de réduction de l'essieu avant russe FAW maintient des niveaux de lubrification optimaux sans aération ni surchauffe.

Logique de réduction: Engrenages coniques et rouleaux coniques

Le coeur du Boîte de réduction de l'essieu avant russe FAW est le Engrenage conique d'entraînement – 1st Essieu avant (Partie no. 2302036A820). Ce pignon présente un profil de dent hypoïde, ce qui permet une plus grande zone de contact et un fonctionnement plus fluide par rapport aux engrenages coniques en spirale. La métallurgie de cet engrenage est spécifiquement formulée pour les couples élevés, rampement à basse vitesse typique des opérations de camion à benne basculante. Il doit résister aux piqûres et à la rupture par fatigue sous des charges extrêmes.

Supportant les immenses charges axiales et radiales générées par l'engrenage hypoïde, les Roulement à rouleaux coniques unités (Numéros de pièces. 30312 et 30314). Le Boîte de réduction de l'essieu avant russe FAW utilise un “rigide” disposition des roulements pour maintenir un alignement précis des engrenages. Si le pignon dévie sous la charge, le motif de contact des dents se déplace, conduisant à du bruit et à une panne rapide. Ces roulements sont préchargés à l'aide du Réglage de la cale – Roulement d'engrenage conique d'entraînement (Partie no. 2402081-557) et séparé par le Entretoise – Roulement d'engrenage conique d'entraînement (Partie no. 2402088-557).

Le réglage précis de cette pile de roulements est l'aspect le plus critique de l'assemblage du Boîte de réduction de l'essieu avant russe FAW. L'épaisseur de la cale détermine la profondeur du pignon et la précharge du roulement.. Dans l'Arctique russe, la contraction thermique du boîtier peut augmenter la précharge du roulement. Donc, les spécifications de configuration pour le Boîte de réduction de l'essieu avant russe FAW sont calibrés pour tenir compte d’une large plage de températures de fonctionnement, s'assurer que les roulements ne se grippent pas lors d'un démarrage à froid ou ne se desserrent pas lors d'un transport lourd.

Antipatinage: Le verrou inter-roues

Une caractéristique déterminante du Boîte de réduction de l'essieu avant russe FAW est son blocage de différentiel inter-roues intégré. Ce système est crucial pour maintenir la mobilité sur la glace. Le mécanisme est actionné pneumatiquement via le Cylindre – Verrouillage du différentiel entre les roues (Partie no. 2406011-A0E) et Piston – Verrouillage du différentiel entre les roues (Partie no. 2406013-A0E). Lorsque le conducteur actionne l'interrupteur, l'air comprimé entre dans le cylindre par le Joint de coude terminal (Partie no. CQ63505), forcer le piston à bouger.

L'étanchéité de ce circuit pneumatique repose sur la Joint torique – Piston de blocage de différentiel (Partie no. 2406014-55R.) et le Joint – Couvercle de cylindre (Partie no. 2406017-A0E). Dans le Boîte de réduction de l'essieu avant russe FAW, ces composants en caoutchouc sont fabriqués à partir de composés à basse température. Les joints toriques standard gèleraient et rétréciraient à -40°C, provoquant des fuites d'air et empêchant le verrouillage de s'enclencher. La fiabilité de ces scellés garantit au conducteur un accès instantané à 6×6 traction en cas de besoin.

Le mouvement du piston est transmis au Fourche de changement de vitesse – Verrouillage du différentiel entre les roues (Partie no. 2306024-820) via le Arbre de fourche de changement de vitesse – Diff inter-roues (Partie no. 2306026-820). Cette fourchette pousse le Manchon d'engrenage coulissant – Diff inter-roues (Partie no. 2306032-820) pour verrouiller les arbres de roue ensemble via le Manchon d'engrenage fixe – Verrouillage du différentiel entre les roues (Partie no. 2306033-820). Le Boîte de réduction de l'essieu avant russe FAW la conception garantit que ce mécanisme est suffisamment robuste pour gérer l'engagement sous charge sans se plier ni se coincer.

Logique du logement: Confinement structurel

Contenant les forces massives du réducteur est le Boîtier de réducteur – 1st Essieu avant (Partie no. 2302018-820). Ce moulage est conçu avec une rigidité extrême pour empêcher la déviation des engrenages. Avec le Capuchon – Roulement de différentiel (Partie no. 2402019-557), il constitue le berceau rigide du Assemblage différentiel – 1st Essieu avant (Partie no. 2303010A820). Le Boîte de réduction de l'essieu avant russe FAW le boîtier est fabriqué à partir de fer nodulaire pour résister à la rupture par choc dans les climats froids.

Le support de différentiel est sécurisé par Broche de soutien – Réducteur & Boîtier d'essieu (Partie no. 2402021-A0E) et Boulon – Chapeau de roulement de différentiel (Partie no. 2402087-A6D). Ces fixations sont essentielles au maintien de la position de la couronne différentielle par rapport au pignon.. Le Bague de réglage – Roulement différentiel (Partie no. 2403071-A8R) permet le réglage précis du jeu et de la précharge du roulement porteur, un réglage qui est verrouillé en place par le Plaque de verrouillage – Bague de réglage (Partie no. 2303072-820).

L'intégrité structurelle est maintenue par une multitude de matériaux à haute résistance Boulons de verrouillage (Numéros de pièces. 2402043-557, 2402016-557, 2302016-820). Ces boulons fixent le boîtier de roulement et le support de différentiel. Le Boîte de réduction de l'essieu avant russe FAW utilise des freins filetés pré-appliqués ou des fonctions de verrouillage mécanique pour empêcher ces boulons de reculer sous les fortes vibrations d'une utilisation hors route. Le grand nombre de boulons reflète les immenses forces internes qui tentent de séparer le carter d'engrenage..

Répartition des composants: 129. Ensemble logique de réducteur d'essieu avant

| Non. |

Numéro de pièce |

Nom de la pièce |

Quantité |

| 1 | 1701471-11 | Écran de verrouillage – 2ème bride d'arbre | 1 |

| 2 | 2502065-557 | Assemblage de bride | 1 |

| 3 | 2302055-820-C00 | Ensemble de joint d'huile pour engrenage conique d'entraînement | 1 |

| 4 | 30312 | Roulement à rouleaux coniques | 1 |

| 5 | 2402081-557 | Réglage de la cale – Roulement d'engrenage conique d'entraînement | 1 |

| 6 | 2402088-557 | Entretoise – Roulement d'engrenage conique d'entraînement | 1 |

| 8 | 2302049-820 | Siège de roulement – 1st Engrenage conique d'entraînement de l'essieu avant | 1 |

| 9 | 2402048-A0E | Bouclier d'huile – Siège de roulement d'engrenage conique d'entraînement | 1 |

| 10 | 30314 | Roulement à rouleaux coniques | 1 |

| 11 | 2302036A820 | Engrenage conique d'entraînement – 1st Essieu avant | 1 |

| 15 | 2306028-820 | Retour printemps – Verrouillage du différentiel entre les roues | 1 |

| 16 | 2306024-820 | Fourche de changement de vitesse – Verrouillage du différentiel entre les roues | 1 |

| 20 | 2406014-55R. | Joint torique – Piston de blocage de différentiel | 1 |

| 21 | 2406013-A0E | Piston – Verrouillage du différentiel entre les roues | 1 |

| 22 | 2406011-A0E | Cylindre – Verrouillage du différentiel entre les roues | 1 |

| 28 | 3774010-55UN | Ensemble interrupteur neutre | 1 |

| 29 | 2306032-820 | Manchon d'engrenage coulissant – Diff inter-roues | 1 |

| 30 | 2306033-820 | Manchon d'engrenage fixe – Verrouillage du différentiel entre les roues | 1 |

| 31 | 2306034-820 | Anneau élastique en fil de fer – Manchon de pignon fixe à verrouillage de différentiel | 1 |

| 32 | 2403071-A8R | Bague de réglage – Roulement différentiel | 2 |

| 35 | 2303072-820 | Plaque de verrouillage – Bague de réglage | 2 |

| 38 | 2303010A820 | Assemblage différentiel – 1st Essieu avant | 1 |

| 39 | 2302015-820 | Boîtier de réducteur & Ensemble de capuchon de roulement de différentiel | 1 |

Conclusion: Le summum de l'ingénierie de traction

Le Boîte de réduction de l'essieu avant russe FAW est plus qu'un simple mécanisme; c'est le catalyseur ultime de la mobilité tout-terrain. En combinant des engrenages hypoïdes de haute précision avec un robuste, blocage de différentiel à commande pneumatique, FAW a créé une unité de traction avant qui offre à la fois une efficacité sur autoroute et une traction hors route imparable.. La sélection minutieuse de matériaux résistants au froid pour les joints et les garnitures garantit le maintien de ces performances même pendant les hivers sibériens les plus rigoureux..

Pour les exploitants de flotte, la complexité de cet assemblage souligne la nécessité de pièces d'origine. La substitution d'un joint générique ou d'un jeu de cales incorrect peut entraîner une défaillance rapide des engrenages coniques ou du blocage du différentiel.. En respectant les spécifications du Boîte de réduction de l'essieu avant russe FAW et en utilisant uniquement des composants authentiques, les équipes de maintenance peuvent garantir la fiabilité et la sécurité à long terme de leur flotte poids lourds.

Emballage et logistique

Pièces FAW, y compris l'ensemble bloc-cylindres, sont emballés avec soin pour garantir une livraison en toute sécurité. Chaque composant est sécurisé dans des matériaux de protection pour éviter tout dommage pendant le transport. Le réseau logistique garantit des expéditions ponctuelles dans le monde entier, soutenir des opérations de maintenance efficaces. Vous trouverez ci-dessous une image illustrant l'emballage standard des pièces de camion FAW., mettant en valeur l’attention portée aux détails dans la manipulation et le stockage.

Cette approche d'emballage minimise le risque de corrosion ou de dommages causés par les chocs., s'assurer que les pièces comme l'ensemble bloc-cylindres FAW arrivent en parfait état. Les clients peuvent compter sur la logistique de FAW pour une qualité et une fiabilité constantes.