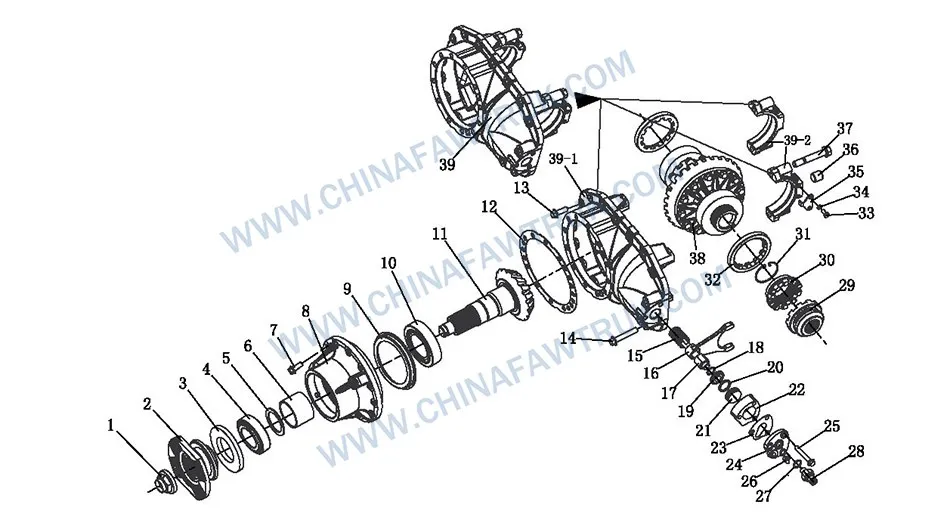

Caja de cambios reductora del eje delantero ruso FAW: Ingeniería 39 Componentes estratégicos para Ultimate 6×6 Tracción

El Caja de cambios reductora del eje delantero ruso FAW El ensamblaje representa la punta de lanza de la capacidad de tracción total del camión volquete CA3250P66K24L1TE5Z.. Situado dentro de la carcasa del eje delantero., Este complejo conjunto lógico gestiona la reducción de marcha primaria y el mecanismo crítico de bloqueo del diferencial entre ruedas.. En la implacable tundra helada de la Federación Rusa, donde la tracción determina la supervivencia, Esta caja de cambios debe convertir la rotación del eje de transmisión de alta velocidad en masiva., par de torsión del suelo. Esta guía completa deconstruye la 39 componentes esenciales, desde el engranaje cónico de accionamiento mecanizado con precisión hasta los actuadores neumáticos de bloqueo del diferencial, asegurando que el Caja de cambios reductora del eje delantero ruso FAW Ofrece un rendimiento inquebrantable en temperaturas tan bajas como -40 °C..

Caja de cambios reductora del eje delantero ruso FAW

Precisión de entrada: Bridas y retenes de aceite

El punto de entrada del poder al Caja de cambios reductora del eje delantero ruso FAW es el Conjunto de brida (Número de pieza. 2502065-557). Este componente forjado de alta resistencia conecta el eje de transmisión delantero al piñón de entrada.. Está asegurado por el alto par Tuerca de bloqueo – 2y brida del eje (Número de pieza. 1701471-11), que aplica la precarga necesaria a la pila de rodamientos. En el Caja de cambios reductora del eje delantero ruso FAW, la rigidez de esta conexión es primordial. Cualquier holgura en la brida se traduce en un juego en los engranajes., que puede romper los dientes bajo las cargas de choque de la conducción todoterreno.

Sellar esta interfaz giratoria contra los duros elementos rusos es el trabajo del Conjunto de sello de aceite del engranaje cónico de transmisión (Número de pieza. 2302055-820-C00). Este no es un sello estándar.; es un multilabio, Sello estilo casete diseñado para funcionar en un ambiente de lodo abrasivo., hielo, y sales químicas para carreteras. La composición del material del sello es crítica para la Caja de cambios reductora del eje delantero ruso FAW. Utiliza fluoroelastómeros avanzados que conservan la flexibilidad a -40°C, asegurando que el aceite para engranajes permanezca dentro de la carcasa y los contaminantes permanezcan afuera.

Además, el Asiento del cojinete – 1st Engranaje cónico de transmisión del eje delantero (Número de pieza. 2302049-820) Proporciona la carcasa estructural para el conjunto de entrada.. Esta pieza fundida está mecanizada con precisión para sujetar las pistas exteriores de los rodamientos de rodillos cónicos.. Cuenta con un integrado Escudo de aceite – Asiento del cojinete del engranaje cónico impulsor (Número de pieza. 2402048-A0E) para gestionar el flujo de petróleo. Este protector evita que el aceite agitado por la corona dentada inunde el cojinete delantero., asegurando que el Caja de cambios reductora del eje delantero ruso FAW Mantiene niveles óptimos de lubricación sin aireación ni sobrecalentamiento..

Lógica de reducción: Engranajes cónicos y rodillos cónicos

El corazón de la Caja de cambios reductora del eje delantero ruso FAW es el Engranaje de bisel – 1eje delantero (Número de pieza. 2302036A820). Este piñón presenta un perfil de diente hipoide., lo que permite una zona de contacto más grande y un funcionamiento más suave en comparación con los engranajes cónicos en espiral. La metalurgia de este engranaje está específicamente formulada para el alto par., avance a baja velocidad típico de las operaciones de camiones volquete. Debe resistir picaduras y fracturas por fatiga bajo cargas extremas..

Soportar las inmensas cargas axiales y radiales generadas por el engranaje hipoide son los Rodamiento de rodillos cónicos unidades (Números de pieza. 30312 y 30314). El Caja de cambios reductora del eje delantero ruso FAW utiliza un “rígido” Disposición de rodamientos para mantener una alineación precisa de los engranajes.. Si el piñón se deforma bajo carga, el patrón de contacto de los dientes cambia, provocando ruido y fallos rápidos.. Estos rodamientos están precargados usando el Ajuste de la cuña – Rodamiento de engranaje cónico de accionamiento (Número de pieza. 2402081-557) y separados por el Espaciador – Rodamiento de engranaje cónico de accionamiento (Número de pieza. 2402088-557).

El ajuste preciso de esta pila de rodamientos es el aspecto más crítico del montaje del Caja de cambios reductora del eje delantero ruso FAW. El espesor de la cuña determina la profundidad del piñón y la precarga del rodamiento.. En el Ártico ruso, La contracción térmica de la carcasa puede aumentar la precarga del rodamiento.. Por lo tanto, las especificaciones de configuración del Caja de cambios reductora del eje delantero ruso FAW Están calibrados para tener en cuenta un amplio rango de temperatura de funcionamiento., asegurar que los cojinetes no se atasquen durante un arranque en frío ni se aflojen durante un transporte pesado.

Control de tracción: El bloqueo entre ruedas

Un rasgo definitorio de la Caja de cambios reductora del eje delantero ruso FAW es su bloqueo del diferencial entre ruedas integrado. Este sistema es crucial para mantener la movilidad sobre el hielo.. El mecanismo se acciona neumáticamente a través del Cilindro – Bloqueo del diferencial entre ruedas (Número de pieza. 2406011-A0E) y Pistón – Bloqueo del diferencial entre ruedas (Número de pieza. 2406013-A0E). Cuando el conductor activa el interruptor, El aire comprimido ingresa al cilindro a través del Articulación terminal del codo (Número de pieza. CQ63505), obligando al pistón a moverse.

La estanqueidad de este circuito neumático depende de la Junta tórica – Pistón de bloqueo del diferencial (Número de pieza. 2406014-55R) y el Empaquetadora – Tapa del cilindro (Número de pieza. 2406017-A0E). En el Caja de cambios reductora del eje delantero ruso FAW, Estos componentes de caucho están hechos de compuestos de baja temperatura.. Las juntas tóricas estándar se congelarían y encogerían a -40°C, causando fugas de aire y evitando que la cerradura se active. La confiabilidad de estos sellos asegura que el conductor tenga acceso instantáneo a 6×6 tracción cuando sea necesario.

El movimiento del pistón se transmite al Horquilla de cambio – Bloqueo del diferencial entre ruedas (Número de pieza. 2306024-820) a través del Eje de la horquilla de cambio – Diferencia entre ruedas (Número de pieza. 2306026-820). Esta horquilla empuja el Manga de engranaje deslizante – Diferencia entre ruedas (Número de pieza. 2306032-820) para bloquear los semiejes entre sí a través del Manga de engranaje fijo – Bloqueo del diferencial entre ruedas (Número de pieza. 2306033-820). El Caja de cambios reductora del eje delantero ruso FAW El diseño garantiza que este mecanismo sea lo suficientemente robusto como para manejar el acoplamiento bajo carga sin doblarse ni atascarse..

Lógica de la vivienda: Contención estructural

Contener las fuerzas masivas del engranaje reductor es el Carcasa reductora – 1eje delantero (Número de pieza. 2302018-820). Esta fundición está diseñada con extrema rigidez para evitar la deflexión del engranaje.. Junto con el Tapa – Cojinete diferencial (Número de pieza. 2402019-557), forma la cuna rígida para el Conjunto diferencial – 1eje delantero (Número de pieza. 2303010A820). El Caja de cambios reductora del eje delantero ruso FAW La carcasa está fabricada de hierro nodular para resistir la fractura por impacto en climas fríos..

El portadiferencial está asegurado por Pasador de soporte – reductor & Carcasa del eje (Número de pieza. 2402021-A0E) y Tornillo – Tapa de cojinete diferencial (Número de pieza. 2402087-A6D). Estos sujetadores son críticos para mantener la posición de la corona del diferencial en relación con el piñón.. El Anillo de ajuste – Rodamiento diferencial (Número de pieza. 2403071-A8R) permite el ajuste preciso de la holgura y la precarga del rodamiento del portador, un ajuste que está bloqueado en su lugar por el Placa de bloqueo – Anillo de ajuste (Número de pieza. 2303072-820).

La integridad estructural se mantiene mediante una multitud de elementos de alta resistencia. Pernos de bloqueo (Números de pieza. 2402043-557, 2402016-557, 2302016-820). Estos pernos aseguran la carcasa del cojinete y el soporte del diferencial.. El Caja de cambios reductora del eje delantero ruso FAW Utiliza bloqueadores de roscas preaplicados o funciones de bloqueo mecánico para evitar que estos pernos se salgan bajo la vibración severa del uso todoterreno.. La gran cantidad de pernos refleja las inmensas fuerzas internas que intentan separar la carcasa del engranaje..

Desglose de componentes: 129. Conjunto lógico del reductor del eje delantero

| No. |

Número de pieza |

Nombre de la pieza |

Cantidad |

| 1 | 1701471-11 | Tuerca de bloqueo – 2y brida del eje | 1 |

| 2 | 2502065-557 | Conjunto de brida | 1 |

| 3 | 2302055-820-C00 | Conjunto de sello de aceite del engranaje cónico de transmisión | 1 |

| 4 | 30312 | Rodamiento de rodillos cónicos | 1 |

| 5 | 2402081-557 | Ajuste de la cuña – Rodamiento de engranaje cónico de accionamiento | 1 |

| 6 | 2402088-557 | Espaciador – Rodamiento de engranaje cónico de accionamiento | 1 |

| 8 | 2302049-820 | Asiento del cojinete – 1st Engranaje cónico de transmisión del eje delantero | 1 |

| 9 | 2402048-A0E | Escudo de aceite – Asiento del cojinete del engranaje cónico impulsor | 1 |

| 10 | 30314 | Rodamiento de rodillos cónicos | 1 |

| 11 | 2302036A820 | Engranaje de bisel – 1eje delantero | 1 |

| 15 | 2306028-820 | Resorte de retorno – Bloqueo del diferencial entre ruedas | 1 |

| 16 | 2306024-820 | Horquilla de cambio – Bloqueo del diferencial entre ruedas | 1 |

| 20 | 2406014-55R | Junta tórica – Pistón de bloqueo del diferencial | 1 |

| 21 | 2406013-A0E | Pistón – Bloqueo del diferencial entre ruedas | 1 |

| 22 | 2406011-A0E | Cilindro – Bloqueo del diferencial entre ruedas | 1 |

| 28 | 3774010-55A | Conjunto de interruptor neutro | 1 |

| 29 | 2306032-820 | Manga de engranaje deslizante – Diferencia entre ruedas | 1 |

| 30 | 2306033-820 | Manga de engranaje fijo – Bloqueo del diferencial entre ruedas | 1 |

| 31 | 2306034-820 | Anillo de retención de alambre – Manga de engranaje fijo de bloqueo del diferencial | 1 |

| 32 | 2403071-A8R | Anillo de ajuste – Rodamiento diferencial | 2 |

| 35 | 2303072-820 | Placa de bloqueo – Anillo de ajuste | 2 |

| 38 | 2303010A820 | Conjunto diferencial – 1eje delantero | 1 |

| 39 | 2302015-820 | Carcasa reductora & Conjunto de tapa de cojinete de diferencial | 1 |

Conclusión: El pináculo de la ingeniería de tracción

El Caja de cambios reductora del eje delantero ruso FAW es más que un simple mecanismo; es el facilitador definitivo de la movilidad todoterreno. Combinando engranajes hipoides de alta precisión con un robusto, bloqueo del diferencial accionado neumáticamente, FAW ha creado una unidad de tracción delantera que ofrece eficiencia en carretera y tracción todoterreno imparable.. La cuidadosa selección de materiales resistentes al frío para sellos y juntas garantiza que este rendimiento se mantenga incluso en los inviernos más duros de Siberia..

Para operadores de flotas, La complejidad de este conjunto subraya la necesidad de piezas originales.. La sustitución de un sello genérico o un paquete de cuñas incorrecto puede provocar una falla rápida de los engranajes cónicos o del bloqueo del diferencial.. Siguiendo las especificaciones del Caja de cambios reductora del eje delantero ruso FAW y utilizando sólo componentes auténticos, Los equipos de mantenimiento pueden garantizar la confiabilidad y seguridad a largo plazo de su flota de vehículos pesados..

Embalaje y Logística

piezas FAW, incluido el conjunto del bloque de cilindros, Se empaquetan con cuidado para garantizar una entrega segura.. Cada componente está asegurado con materiales protectores para evitar daños durante el transporte.. La red logística garantiza envíos puntuales en todo el mundo., apoyando operaciones de mantenimiento eficientes. A continuación se muestra una imagen que ilustra el embalaje estándar de las piezas de camiones FAW., mostrando la atención al detalle en el manejo y almacenamiento.

Este enfoque de embalaje minimiza el riesgo de corrosión o daños por impacto., asegurando que piezas como el conjunto de bloque de cilindros FAW lleguen en perfectas condiciones. Los clientes pueden confiar en la logística de FAW para obtener calidad y confiabilidad constantes.