Carcasa del eje delantero ruso FAW: Fortificante 7 Componentes críticos para la durabilidad del Ártico

El Carcasa del eje delantero ruso FAW assembly forms the structural core of the CA3250P66K24L1TE5Z dump truck. It supports the engine’s weight while managing steering articulation. In the frozen terrain of Russia, this assembly withstands shock loads that would shatter lesser castings. Esta guía detalla la 7 key components ensuring reliable operation at -40°C.

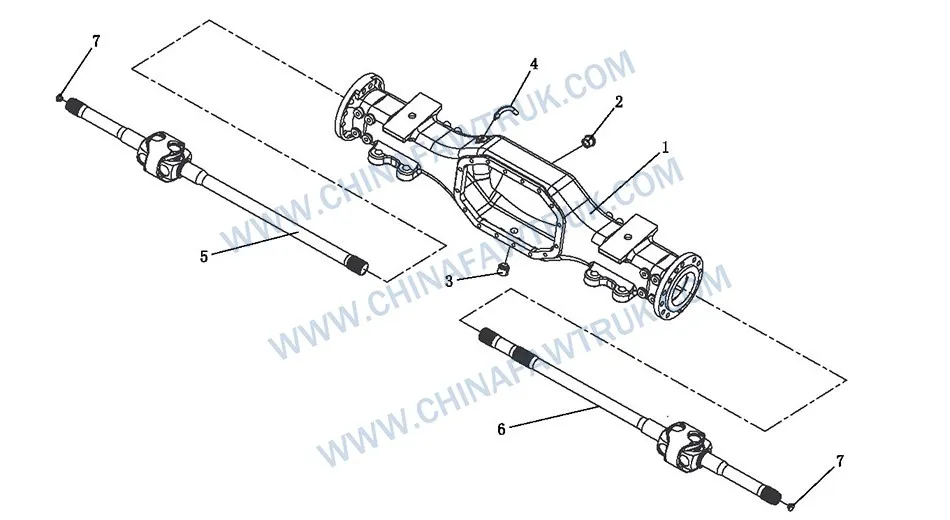

FAW Russian Front Axle Housing Logic Assembly

Metallurgical Fortress: The Axle Housing

La pieza central de esta asamblea es la Carcasa del eje – First Front Axle (Número de pieza. 2301011-820). En la jerarquía de ingeniería de la Carcasa del eje delantero ruso FAW, this component is the single most critical structural element. It functions as a load-bearing bridge rather than just a container. The housing is manufactured from specialized nodular graphite iron. This selection is driven by the Russian market, where standard iron becomes brittle at -30°C.

The alloy used in the Carcasa del eje delantero ruso FAW contains nickel additives to maintain ductility. Esto evita “cold shortness,” a failure mode where metal shatters under impact. The design incorporates complex internal ribbing and variable wall thickness. These features are optimized to distribute vertical loads from the suspension and lateral loads from cornering. The central “banjo” section is reinforced to resist the separating forces of the ring gears.

Protection against corrosion is vital for the Carcasa del eje delantero ruso FAW. The exterior surface is treated with a heavy-duty coating to withstand road salts. In the corrosive slurry of a mining road, untreated metal degrades rapidly. FAW’s treatment ensures the structural integrity is not compromised by rust. The robustness of this casting defines the durability of the front drive system.

Steering Power: The Double Universal Joints

Transmitting power to steering wheels requires a sophisticated solution. El Carcasa del eje delantero ruso FAW utiliza el Left Axle Shaft and Double Universal Joint Assembly (Número de pieza. 2303080-820). It also employs the Right Axle Shaft and Double Universal Joint Assembly (Número de pieza. 2303090-820). Unlike rigid rear axles, these shafts must articulate up to 40 grados. A standard U-joint cannot transmit smooth torque at these angles without binding.

El “Double Universal Joint” design within the Carcasa del eje delantero ruso FAW creates a Constant Velocity (CV) efecto. By placing two U-joints back-to-back, velocity fluctuations are cancelled out. This ensures power flows smoothly to the wheels during turns. This is crucial in 6×6 mode on slippery surfaces. If torque delivery were pulsating, it would break traction, causing the truck to slide sideways.

The axle shafts, designated by the “820” sufijo, are heavy-duty components. They are forged from induction-hardened steel to resist torsional fatigue. dentro del Carcasa del eje delantero ruso FAW, these shafts float on bushings. They are supported by internal thrust components to maintain positioning. This prevents the shaft from “caminando” inward during turns, protecting the differential seals.

Lógica de sellado: Plugs and Breathers

Longevidad del Carcasa del eje delantero ruso FAW depends on oil cleanliness. El montaje incluye el Tapón cónico de cabeza hexagonal (Número de pieza. CQ61810). It also features the Tapón magnético cónico con casquillo hexagonal (Número de pieza. T62104M). The magnetic plug captures ferrous contaminants shed by gears. This prevents metal particles from circulating and acting as abrasive paste in the bearings.

Pressure management is handled by the Tapón de respiradero (Número de pieza. T905). Internal air expands as the differential heats up. sin respiro, pressure blows out the seals of the Carcasa del eje delantero ruso FAW. En cambio, rapid cooling creates a vacuum that sucks in water. The T905 acts as a check valve, allowing equalization while blocking contaminants.

The tapered thread design of the plugs ensures a leak-proof seal. This eliminates the need for perishable gaskets that fail in the cold. The interference fit resists loosening from vibration. En el Carcasa del eje delantero ruso FAW, a sealed environment is paramount. Fluid loss in the Arctic could lead to a seized axle, making these plugs critical for mission success.

Axial Control: The Function of Thrust Blocks

Hidden within the Carcasa del eje delantero ruso FAW are two units of the Thrust Block (Número de pieza. 2303086-820). These components perform a vital function in a steering drive axle. As the vehicle turns, steering geometry pulls on the axle shafts. Without a physical stop, shafts could be pulled out of the differential. This would lead to spline damage or disengagement.

The thrust blocks provide a hardened wear surface. They maintain the correct axial position of the axle shafts within the Carcasa del eje delantero ruso FAW. These blocks are often adjustable to set precise end-play. Incorrect end-play leads to binding or seal leaks. The blocks ensure the shafts remain seated against the differential side gears during extreme articulation.

The material is typically high-grade bronze or surface-hardened steel. They withstand high compressive loads and friction. In cold-start conditions relevant to the Carcasa del eje delantero ruso FAW, resistance to galling is key. Their durability ensures that the complex double-cardan joints remain aligned with the steering axis. This component safeguards the internal geometry of the entire front drive system.

Desglose de componentes: 128. Front Axle Housing and Axle Shaft Logic Assembly

| No. |

Número de pieza |

Nombre de la pieza |

Cantidad |

| 1 |

2301011-820 |

Carcasa del eje – First Front Axle |

1 |

| 2 |

CQ61810 |

Tapón cónico de cabeza hexagonal |

1 |

| 3 |

T62104M |

Tapón magnético cónico con casquillo hexagonal |

1 |

| 4 |

T905 |

Tapón de respiradero |

1 |

| 5 |

2303080-820 |

Left Axle Shaft and Double Universal Joint Assembly |

1 |

| 6 |

2303090-820 |

Right Axle Shaft and Double Universal Joint Assembly |

1 |

| 7 |

2303086-820 |

Thrust Block |

2 |

Conclusión: The Structural Core of All-Wheel Drive

El Carcasa del eje delantero ruso FAW assembly is more than just a rigid beam; it is a complex mechanical system that enables the 6×6 capability of the vehicle. By integrating the load-bearing strength of the housing with the articulation precision of the double universal joint axle shafts, FAW has created a front-end solution capable of conquering the Arctic. The inclusion of maintenance-focused components like magnetic plugs and breathers demonstrates a commitment to long-term durability.

Para propietarios de flotas, the structural integrity of the Carcasa del eje delantero ruso FAW is the foundation of vehicle safety and performance. Regular checks of the breather plug and oil condition can prevent costly internal damage. When repairs are needed, using genuine parts for the axle shafts and housing components is essential to maintain the factory-engineered tolerances and metallurgical standards required for operation in the harsh Russian environment.

Embalaje y Logística

piezas FAW, incluido el conjunto del bloque de cilindros, Se empaquetan con cuidado para garantizar una entrega segura.. Cada componente está asegurado con materiales protectores para evitar daños durante el transporte.. La red logística garantiza envíos puntuales en todo el mundo., apoyando operaciones de mantenimiento eficientes. A continuación se muestra una imagen que ilustra el embalaje estándar de las piezas de camiones FAW., mostrando la atención al detalle en el manejo y almacenamiento.

Este enfoque de embalaje minimiza el riesgo de corrosión o daños por impacto., asegurando que piezas como el conjunto de bloque de cilindros FAW lleguen en perfectas condiciones. Los clientes pueden confiar en la logística de FAW para obtener calidad y confiabilidad constantes.