Российский передний редуктор FAW: Инженерное дело 39 Стратегические компоненты для Ultimate 6×6 Тяга

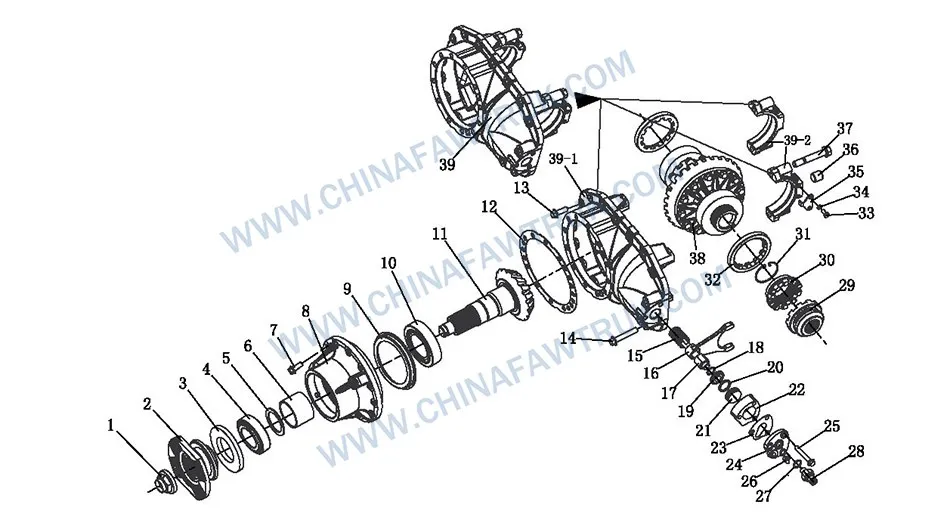

The Российский передний редуктор FAW assembly represents the spearhead of the CA3250P66K24L1TE5Z dump truck’s all-wheel-drive capability. Situated within the front axle housing, this intricate logic assembly manages the primary gear reduction and the critical inter-wheel differential locking mechanism. В беспощадной замерзшей тундре Российской Федерации, where traction determines survival, this gearbox must convert high-speed driveshaft rotation into massive, ground-churning torque. Это подробное руководство деконструирует 39 основные компоненты, from the precision-machined drive bevel gear to the pneumatic differential lock actuators, обеспечение того, чтобы Российский передний редуктор FAW обеспечивает непревзойденную производительность при температурах до -40°C.

Российский передний редуктор FAW

Input Precision: Flanges and Oil Seals

The entry point for power into the Российский передний редуктор FAW это Flange Assembly (Часть №. 2502065-557). This heavy-duty forged component connects the front driveshaft to the input pinion. It is secured by the high-torque Контргайка – 2nd Shaft Flange (Часть №. 1701471-11), which applies the necessary preload to the bearing stack. В Российский передний редуктор FAW, the rigidity of this connection is paramount. Any looseness at the flange translates to backlash in the gears, which can shatter the teeth under the shock loads of off-road driving.

Sealing this rotating interface against the harsh Russian elements is the job of the Узел сальника ведущей конической шестерни (Часть №. 2302055-820-С00). This is not a standard seal; it is a multi-lip, cassette-style seal designed to operate in an environment of abrasive mud, лед, and chemical road salts. The material composition of the seal is critical for the Российский передний редуктор FAW. It utilizes advanced fluoroelastomers that retain flexibility at -40°C, ensuring that the gear oil remains inside the housing and contaminants remain out.

Более того, а Седло подшипника – 1st Front Axle Drive Bevel Gear (Часть №. 2302049-820) provides the structural housing for the input assembly. This casting is precision-machined to hold the outer races of the tapered roller bearings. It features an integrated Нефтяной щит – Посадочное место подшипника ведущей конической шестерни (Часть №. 2402048-А0Е) to manage oil flow. This shield prevents oil churned by the ring gear from flooding the front bearing, обеспечение того, чтобы Российский передний редуктор FAW maintains optimal lubrication levels without aeration or overheating.

Логика сокращения: Bevel Gears and Tapered Rollers

Сердце Российский передний редуктор FAW это Приводная коническая шестерня – 1передний мост (Часть №. 2302036А820). This pinion gear features a hypoid tooth profile, which allows for a larger contact patch and smoother operation compared to spiral bevel gears. The metallurgy of this gear is specifically formulated for the high-torque, low-speed crawling typical of dump truck operations. It must resist pitting and fatigue fracture under extreme loads.

Supporting the immense axial and radial loads generated by the hypoid gear mesh are the Конический ролик единицы (Номера деталей. 30312 и 30314). The Российский передний редуктор FAW использует “жесткий” bearing arrangement to maintain precise gear alignment. If the pinion gear deflects under load, the tooth contact pattern shifts, leading to noise and rapid failure. These bearings are preloaded using the Регулировка прокладки – Подшипник ведущей конической шестерни (Часть №. 2402081-557) and separated by the Проставка – Подшипник ведущей конической шестерни (Часть №. 2402088-557).

The precise adjustment of this bearing stack is the most critical aspect of assembling the Российский передний редуктор FAW. The shim thickness determines the pinion depth and bearing preload. В Российской Арктике, thermal contraction of the housing can increase bearing preload. Поэтому, the setup specifications for the Российский передний редуктор FAW are calibrated to account for a wide operating temperature range, ensuring the bearings do not seize during a cold start or become loose during heavy hauling.

Контроль тяги: The Inter-Wheel Lock

Определяющая особенность Российский передний редуктор FAW is its integrated inter-wheel differential lock. This system is crucial for maintaining mobility on ice. The mechanism is pneumatically actuated via the Цилиндр – Блокировка межколесного дифференциала (Часть №. 2406011-А0Е) и Поршень – Блокировка межколесного дифференциала (Часть №. 2406013-А0Е). When the driver activates the switch, compressed air enters the cylinder through the Терминальный локтевой сустав (Часть №. CQ63505), forcing the piston to move.

The sealing of this pneumatic circuit relies on the Упплужденное кольцо – Поршень блокировки дифференциала (Часть №. 2406014-55р) и Прокладка – Крышка цилиндра (Часть №. 2406017-А0Е). В Российский передний редуктор FAW, these rubber components are made from low-temperature compounds. Standard O-rings would freeze and shrink at -40°C, causing air leaks and preventing the lock from engaging. The reliability of these seals ensures that the driver has instant access to 6×6 traction when needed.

The piston movement is transmitted to the Сдвиг вилка – Блокировка межколесного дифференциала (Часть №. 2306024-820) via the Shift Fork Shaft – Inter-wheel Diff (Часть №. 2306026-820). This fork pushes the Скользящая втулка шестерни – Inter-wheel Diff (Часть №. 2306032-820) to lock the axle shafts together via the Фиксированная зубчатая втулка – Блокировка межколесного дифференциала (Часть №. 2306033-820). The Российский передний редуктор FAW design ensures that this mechanism is robust enough to handle engagement under load without bending or jamming.

Жилищная логика: Структурное сдерживание

Containing the massive forces of the reduction gear is the Корпус редуктора – 1передний мост (Часть №. 2302018-820). This casting is designed with extreme rigidity to prevent gear deflection. Along with the Кепка – Подшипник дифференциала (Часть №. 2402019-557), it forms the rigid cradle for the Дифференциальная сборка – 1передний мост (Часть №. 2303010А820). The Российский передний редуктор FAW housing is manufactured from nodular iron to resist shock fracturing in cold climates.

The differential carrier is secured by Поддержка Pin – Редуктор & Корпус оси (Часть №. 2402021-А0Е) и Болт – Diff Bearing Cap (Часть №. 2402087-A6D). These fasteners are critical for maintaining the position of the differential ring gear relative to the pinion. The Регулировочное кольцо – Дифференциальный подшипник (Часть №. 2403071-A8R) allows for the precise setting of backlash and carrier bearing preload, a setting that is locked in place by the Запирающая пластина – Регулировочное кольцо (Часть №. 2303072-820).

Structural integrity is maintained by a multitude of high-tensile Lock Bolts (Номера деталей. 2402043-557, 2402016-557, 2302016-820). These bolts secure the bearing housing and the differential carrier. The Российский передний редуктор FAW utilizes pre-applied thread lockers or mechanical locking features to prevent these bolts from backing out under the severe vibration of off-road use. The sheer number of bolts reflects the immense internal forces trying to separate the gear housing.

Разбивка компонентов: 129. Front Axle Reducer Logic Assembly

| Нет. |

Номер детали |

Наименование |

Кол-во |

| 1 | 1701471-11 | Контргайка – 2nd Shaft Flange | 1 |

| 2 | 2502065-557 | Flange Assembly | 1 |

| 3 | 2302055-820-С00 | Узел сальника ведущей конической шестерни | 1 |

| 4 | 30312 | Конический ролик | 1 |

| 5 | 2402081-557 | Регулировка прокладки – Подшипник ведущей конической шестерни | 1 |

| 6 | 2402088-557 | Проставка – Подшипник ведущей конической шестерни | 1 |

| 8 | 2302049-820 | Седло подшипника – 1st Front Axle Drive Bevel Gear | 1 |

| 9 | 2402048-А0Е | Нефтяной щит – Посадочное место подшипника ведущей конической шестерни | 1 |

| 10 | 30314 | Конический ролик | 1 |

| 11 | 2302036А820 | Приводная коническая шестерня – 1передний мост | 1 |

| 15 | 2306028-820 | ВЕРНАЯ ВЕСНА – Блокировка межколесного дифференциала | 1 |

| 16 | 2306024-820 | Сдвиг вилка – Блокировка межколесного дифференциала | 1 |

| 20 | 2406014-55р | Упплужденное кольцо – Поршень блокировки дифференциала | 1 |

| 21 | 2406013-А0Е | Поршень – Блокировка межколесного дифференциала | 1 |

| 22 | 2406011-А0Е | Цилиндр – Блокировка межколесного дифференциала | 1 |

| 28 | 3774010-55А | Neutral Switch Assembly | 1 |

| 29 | 2306032-820 | Скользящая втулка шестерни – Inter-wheel Diff | 1 |

| 30 | 2306033-820 | Фиксированная зубчатая втулка – Блокировка межколесного дифференциала | 1 |

| 31 | 2306034-820 | Проволочное стопорное кольцо – Фиксированная втулка шестерни блокировки дифференциала | 1 |

| 32 | 2403071-A8R | Регулировочное кольцо – Дифференциальный подшипник | 2 |

| 35 | 2303072-820 | Запирающая пластина – Регулировочное кольцо | 2 |

| 38 | 2303010А820 | Дифференциальная сборка – 1передний мост | 1 |

| 39 | 2302015-820 | Корпус редуктора & Крышка подшипника дифференциала в сборе | 1 |

Заключение: Вершина тягового машиностроения

The Российский передний редуктор FAW is more than just a mechanism; it is the ultimate enabler of all-terrain mobility. Сочетая высокоточные гипоидные передачи с прочной, пневматическая блокировка дифференциала, FAW has created a front drive unit that offers both highway efficiency and unstoppable off-road traction. Тщательный подбор морозостойких материалов для уплотнений и прокладок гарантирует сохранение этих характеристик даже в самые суровые сибирские зимы..

Для операторов автопарка, сложность этой сборки подчеркивает необходимость использования оригинальных запчастей.. Замена штатного уплотнения или неправильного пакета прокладок может привести к быстрому выходу из строя конических шестерен или блокировки дифференциала.. Соблюдая технические характеристики, Российский передний редуктор FAW и использование только оригинальных компонентов, команды технического обслуживания могут гарантировать долгосрочную надежность и безопасность своего тяжелого парка техники..

Упаковка и логистика

Запчасти ФАВ, включая блок цилиндров в сборе, тщательно упакованы, чтобы обеспечить безопасную доставку. Каждый компонент закреплен защитными материалами для предотвращения повреждений при транспортировке.. Логистическая сеть гарантирует своевременную доставку по всему миру., поддержка эффективных операций по техническому обслуживанию. Ниже приведено изображение, иллюстрирующее стандартную упаковку запчастей для грузовиков FAW., демонстрация внимания к деталям в обращении и хранении.

Такой подход к упаковке сводит к минимуму риск коррозии или ударного повреждения., обеспечение доставки таких деталей, как блок цилиндров FAW в сборе, в идеальном состоянии.. Клиенты могут положиться на логистику FAW для обеспечения стабильного качества и надежности..