Дифференциал переднего моста FAW Русский: оркестровка 13 Стратегические компоненты для Superior 6×6 Тяга

The Дифференциал переднего моста FAW Русский узел представляет собой кинетическое сердце системы переднего привода самосвала CA3250P66K24L1TE5Z.. Расположен глубоко внутри картера переднего моста., этот сложный механизм отвечает за распределение крутящего момента между левым и правым передними колесами, обеспечивая при этом необходимые изменения скорости во время поворотов.. В беспощадной замерзшей тундре Российской Федерации, где тяга определяет разницу между успешной перевозкой и застрявшим транспортным средством, этот дифференциал должен преобразовывать входной сигнал с высоким крутящим моментом в контролируемую мощность заземления.. Это подробное руководство деконструирует 13 основные компоненты, от массивной ведомой конической шестерни до прецизионных планетарных передач, обеспечение того, чтобы Дифференциал переднего моста FAW Русский обеспечивает непревзойденную производительность при температурах до -40°C.

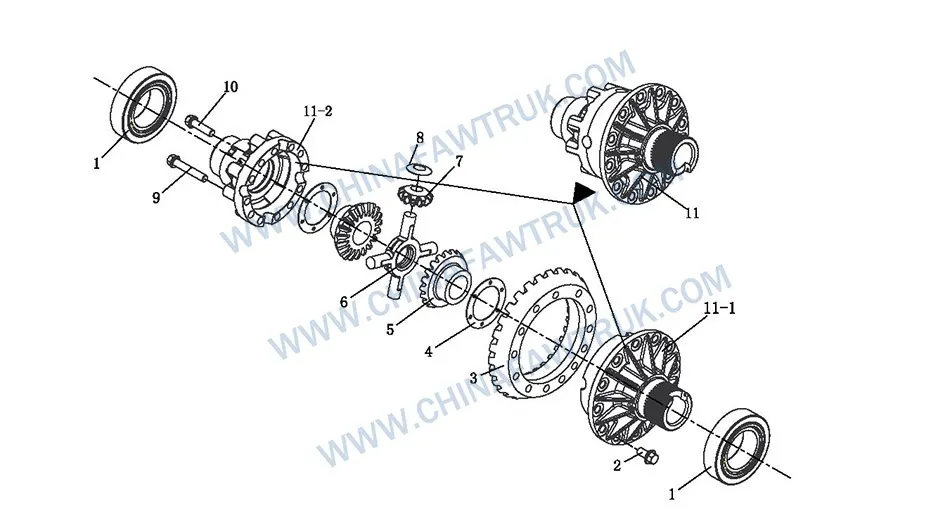

Российский дифференциал переднего моста FAW в сборе

Динамика передач: Приводной конус и планетарная система

Первичная точка входа крутящего момента для Дифференциал переднего моста FAW Русский это массивный Ведомая коническая шестерня – 1передний мост (Часть №. 2302037А820). Эта большая коронная шестерня входит в зацепление с входной шестерней, создавая передаточное число главной передачи.. В контексте самосвала CA3250P66K24L1TE5Z, металлургия этой шестерни имеет решающее значение. Он действует как рычаг, который увеличивает крутящий момент двигателя для вращения тяжелого корпуса дифференциала.. The “А820” суффикс указывает на особый профиль термообработки, предназначенный для выдерживания экстремальных точечных и ударных нагрузок, связанных с работой в горнодобывающей отрасли России., где колеса часто скользят по льду, прежде чем внезапно вцепиться в сухую скалу.

Внутри носителя, Распределением власти занимается “паук” сборка, сосредоточено вокруг Крестовый вал – Дифференциал (Часть №. 2403061-А5Д). Этот четырехточечный вал поддерживает Планетарная передача единицы (Часть №. 2403056-А5Д). Когда грузовик поворачивает, эти планетарные шестерни вращаются на поперечном валу, allowing the left and right wheels to spin at different speeds. The precision machining of the cross shaft trunnions is vital for the Дифференциал переднего моста FAW Русский; any surface roughness here would lead to rapid wear of the planetary gear bores, causing excessive backlash and eventual driveline clunk.

The planetary gears mesh with the Шестерня вала оси (Часть №. 2303051-820), also known as side gears. These splined gears connect directly to the axle shafts, transmitting the final driving force to the wheels. В Дифференциал переднего моста FAW Русский, the tooth profile of these side gears is optimized for maximum contact area. This design minimizes the risk of tooth fracture under high-torque starts, a common scenario when a fully loaded truck attempts to climb a grade out of a muddy pit. Взаимодействие между планетарными шестернями и шестернями полуосей создает дифференциальное действие, которое является основной функцией узла..

Жилищная логика: Сборка дифференциального корпуса

Герметизация зубчатой передачи – это Корпус дифференциала в сборе (Часть №. 2303015А820). Этот жесткий корпус представляет собой разъемную конструкцию., состоит из Левый корпус – Дифференциал (Часть №. 2303017А820) и Правильный случай – Дифференциал (Часть №. 2303018-820). Конструктивная жесткость в этом случае имеет первостепенное значение для Дифференциал переднего моста FAW Русский. Под нагрузкой, шестерни внутри пытаются раздвинуться; корпус должен выдерживать эти разделяющие силы, не прогибаясь. Если дело искажает, выравнивание зубчатого зацепления потеряно, приводящие к катастрофическому провалу.

Половины корпуса изготавливаются из высококачественного шаровидного чугуна или литой стали., выбраны из-за их превосходной пластичности при низких температурах. В Российской Арктике, стандартный чугун может стать хрупким и растрескаться при ударе. Материал, использованный в Дифференциал переднего моста FAW Русский Корпус гарантирует сохранение прочности даже при температуре -40°C.. The mating surfaces of the left and right cases are precision-ground to ensure a perfect seal and alignment, preventing oil leakage and ensuring concentric rotation of the internal components.

Securing the two halves of the case together requires high-tensile fasteners. The assembly utilizes multiple units of Lock Bolt (Часть №. 2303023-820) и Lock Bolt (Часть №. 2303024-820). These bolts are not merely tightened; they are torqued to yield and often feature pre-applied thread locking compounds. The Дифференциал переднего моста FAW Русский relies on the clamping force of these bolts to maintain the structural unity of the differential case spinning at high RPMs. A loose bolt here would be disastrous, destroying the axle housing from the inside out.

Wear Control: Washers and Shims

Within the spinning differential, metal-on-metal friction is the enemy. The Дифференциал переднего моста FAW Русский employs specific thrust washers to manage this wear. The Шайба – Планетарная передача (Часть №. 2403058-А5Д) is a spherical washer that sits between the planetary gear and the differential case. It absorbs the centrifugal force pushing the gear outward and provides a sacrificial wear surface. Without these washers, the gears would grind directly into the iron case, ruining it.

Сходным образом, а Шайба – Шестерня вала оси (Часть №. 2303053-820) is positioned behind the side gears. These flat thrust washers handle the separating forces generated by the bevel gear mesh. In the heavy-duty application of the Дифференциал переднего моста FAW Русский, these washers are often made from bronze alloys or hardened steel with oil grooves to promote hydrodynamic lubrication. Ensuring a continuous oil film in extreme cold is critical to preventing galling and seizure.

The thickness of these washers also plays a role in setting the internal gear backlash. The Дифференциал переднего моста FAW Русский requires precise backlash to function correctly. Слишком сильный удар приводит к стуку и ударным нагрузкам.; слишком мало вызывает заедание и перегрев. Во время сборки или ремонта, Выбор правильной толщины шайбы — это точная задача, от которой зависит плавность хода и долговечность всей системы переднего моста..

Логика вращения: Подшипники и крепеж

Поддержка всего корпуса дифференциала во время его вращения внутри картера моста является Конический ролик единицы (Часть №. 32214/Я6). Эти подшипники подвергаются комбинированным нагрузкам.: радиальный вес дифференциала в сборе и осевое усилие, создаваемое зацеплением кольца и шестерни. The “Я6” суффикс, вероятно, обозначает конкретный внутренний зазор или материал сепаратора, оптимизированный для Дифференциал переднего моста FAW Русский. Правильная предварительная нагрузка на эти подшипники необходима для предотвращения отклонения водила под нагрузкой..

Крепление зубчатого венца к корпусу дифференциала является наиболее ответственным крепежным соединением всей оси.. В сборке используется 12 единицы Lock Bolt (Часть №. 2402063-557) для этой цели. Эти болты должны передавать полный крутящий момент двигателя.. В Дифференциал переднего моста FAW Русский, эти болты обычно имеют фланцевую головку для распределения давления и устанавливаются с определенной последовательностью крутящего момента и угла..

Если эти болты ослабнут, зубчатый венец будет раскачиваться, разрушение ведущей шестерни и возможная блокировка передних колес. Надежная конструкция Дифференциал переднего моста FAW Русский Крепежи гарантируют, что это соединение останется прочным на протяжении всего срока службы автомобиля., даже в условиях суровых циклов остановки и запуска карьерного самосвала. Материаловедение, лежащее в основе этих болтов, отдает приоритет высокой прочности на разрыв и сопротивлению срезающим силам..

Разбивка компонентов: 130. Дифференциал переднего моста в сборе

| Нет. |

Номер детали |

Наименование |

Кол-во |

| 1 | 32214/Я6 | Конический ролик | 2 |

| 2 | 2402063-557 | Lock Bolt | 12 |

| 3 | 2302037А820 | Ведомая коническая шестерня – 1передний мост | 1 |

| 4 | 2303053-820 | Шайба – Шестерня вала оси | 2 |

| 5 | 2303051-820 | Шестерня вала оси | 2 |

| 6 | 2403061-А5Д | Крестовый вал – Дифференциал | 1 |

| 7 | 2403056-А5Д | Планетарная передача | 4 |

| 8 | 2403058-А5Д | Шайба – Планетарная передача | 4 |

| 9 | 2303023-820 | Lock Bolt | 8 |

| 10 | 2303024-820 | Lock Bolt | 4 |

| 11 | 2303015А820 | Корпус дифференциала в сборе | 1 |

| 11-1 | 2303017А820 | Левый корпус – Дифференциал | 1 |

| 11-2 | 2303018-820 | Правильный случай – Дифференциал | 1 |

Заключение: Ядро 6×6 Надежность

The Дифференциал переднего моста FAW Русский is the defining component that enables the CA3250P66K24L1TE5Z to operate effectively in the extreme conditions of the Russian North. Его прочная конструкция, featuring cold-tough case materials, precision-machined gears, and durable wear components, ensures that the front wheels contribute meaningful traction when it matters most. Каждая часть, from the cross shaft to the lock bolts, plays a vital role in this synergy.

Для ремонтных бригад, the lesson is one of precision and quality. Rebuilding a differential is a complex task where tolerances are measured in hundredths of a millimeter. Using generic gears or bearings risks catastrophic failure that can immobilize the truck. Инвестируя в настоящие Дифференциал переднего моста FAW Русский набор, operators ensure that their vehicle’s front drive system remains a reliable asset, capable of conquering the toughest terrain the planet has to offer.

Упаковка и логистика

Запчасти ФАВ, включая блок цилиндров в сборе, тщательно упакованы, чтобы обеспечить безопасную доставку. Каждый компонент закреплен защитными материалами для предотвращения повреждений при транспортировке.. Логистическая сеть гарантирует своевременную доставку по всему миру., поддержка эффективных операций по техническому обслуживанию. Ниже приведено изображение, иллюстрирующее стандартную упаковку запчастей для грузовиков FAW., демонстрация внимания к деталям в обращении и хранении.

Такой подход к упаковке сводит к минимуму риск коррозии или ударного повреждения., обеспечение доставки таких деталей, как блок цилиндров FAW в сборе, в идеальном состоянии.. Клиенты могут положиться на логистику FAW для обеспечения стабильного качества и надежности..