FAW الروسية المحور التفاضلي الأمامي: التنسيق 13 المكونات الاستراتيجية للمتفوقين 6×6 الجر

ال FAW الروسية المحور التفاضلي الأمامي assembly represents the kinetic heart of the front drive system in the CA3250P66K24L1TE5Z dump truck. Situated deep within the front axle housing, this intricate mechanism is responsible for distributing torque between the left and right front wheels while allowing for necessary speed variations during turning maneuvers. في التندرا المجمدة التي لا ترحم في الاتحاد الروسي, where traction determines the difference between a successful haul and a stranded vehicle, this differential must convert high-torque input into controllable ground power. هذا الدليل الشامل يفكك 13 المكونات الأساسية, from the massive driven bevel gear to the precision planetary gear sets, التأكد من أن FAW الروسية المحور التفاضلي الأمامي يوفر أداءً لا ينضب في درجات حرارة منخفضة تصل إلى -40 درجة مئوية.

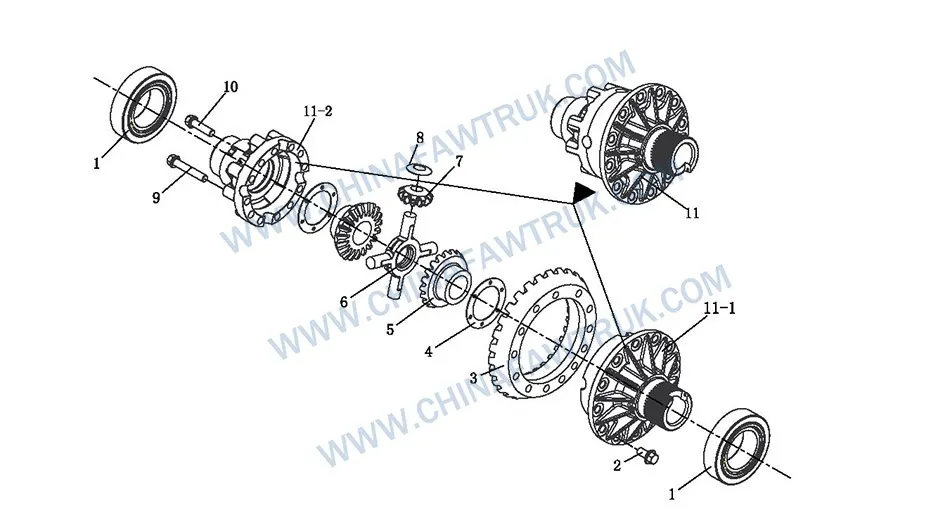

FAW Russian Front Axle Differential Assembly

Gear Dynamics: The Driven Bevel and Planetary System

The primary torque entry point for the FAW الروسية المحور التفاضلي الأمامي is the massive مدفوعة شطبة والعتاد – 1المحور الأمامي الحادي (الجزء لا. 2302037A820). This large ring gear meshes with the input pinion to create the final drive reduction ratio. In the context of the CA3250P66K24L1TE5Z dump truck, the metallurgy of this gear is critical. It acts as the lever that multiplies engine torque to rotate the heavy differential case. ال “A820” suffix indicates a specific heat-treatment profile designed to resist the extreme pitting and shock loads associated with operating in the Russian mining sector, where wheels often slip on ice before suddenly gripping dry rock.

Inside the carrier, the distribution of power is handled by the “العنكبوت” حَشد, centered around the رمح عبر – التفاضلي (الجزء لا. 2403061-A5D). This four-point shaft supports the العتاد الكوكبي وحدات (الجزء لا. 2403056-A5D). كما زوايا الشاحنة, these planetary gears rotate on the cross shaft, allowing the left and right wheels to spin at different speeds. The precision machining of the cross shaft trunnions is vital for the FAW الروسية المحور التفاضلي الأمامي; any surface roughness here would lead to rapid wear of the planetary gear bores, causing excessive backlash and eventual driveline clunk.

The planetary gears mesh with the جير رمح المحور (الجزء لا. 2303051-820), also known as side gears. These splined gears connect directly to the axle shafts, transmitting the final driving force to the wheels. في FAW الروسية المحور التفاضلي الأمامي, the tooth profile of these side gears is optimized for maximum contact area. This design minimizes the risk of tooth fracture under high-torque starts, a common scenario when a fully loaded truck attempts to climb a grade out of a muddy pit. The interaction between the planetary gears and the axle shaft gears creates the differential action that is the core function of the assembly.

منطق الإسكان: The Differential Case Assembly

Encapsulating the gear train is the تجميع الحالة التفاضلية (الجزء لا. 2303015A820). This rigid housing is a split design, composed of the الحالة اليسرى – التفاضلي (الجزء لا. 2303017A820) و القضية الصحيحة – التفاضلي (الجزء لا. 2303018-820). The structural rigidity of this case is paramount for the FAW الروسية المحور التفاضلي الأمامي. Under load, the gears inside try to push apart; the case must contain these separating forces without flexing. If the case distorts, gear mesh alignment is lost, مما يؤدي إلى فشل ذريع.

The halves of the case are machined from high-grade nodular iron or cast steel, chosen for their superior ductility at low temperatures. في القطب الشمالي الروسي, standard cast iron can become brittle and crack under impact. المواد المستخدمة في FAW الروسية المحور التفاضلي الأمامي case ensures that it retains its toughness even at -40°C. The mating surfaces of the left and right cases are precision-ground to ensure a perfect seal and alignment, preventing oil leakage and ensuring concentric rotation of the internal components.

Securing the two halves of the case together requires high-tensile fasteners. The assembly utilizes multiple units of Lock Bolt (الجزء لا. 2303023-820) و Lock Bolt (الجزء لا. 2303024-820). These bolts are not merely tightened; they are torqued to yield and often feature pre-applied thread locking compounds. ال FAW الروسية المحور التفاضلي الأمامي relies on the clamping force of these bolts to maintain the structural unity of the differential case spinning at high RPMs. A loose bolt here would be disastrous, destroying the axle housing from the inside out.

Wear Control: Washers and Shims

Within the spinning differential, metal-on-metal friction is the enemy. ال FAW الروسية المحور التفاضلي الأمامي employs specific thrust washers to manage this wear. ال غسالة – العتاد الكوكبي (الجزء لا. 2403058-A5D) is a spherical washer that sits between the planetary gear and the differential case. It absorbs the centrifugal force pushing the gear outward and provides a sacrificial wear surface. بدون هذه الغسالات, the gears would grind directly into the iron case, ruining it.

بصورة مماثلة, ال غسالة – جير رمح المحور (الجزء لا. 2303053-820) is positioned behind the side gears. These flat thrust washers handle the separating forces generated by the bevel gear mesh. In the heavy-duty application of the FAW الروسية المحور التفاضلي الأمامي, these washers are often made from bronze alloys or hardened steel with oil grooves to promote hydrodynamic lubrication. Ensuring a continuous oil film in extreme cold is critical to preventing galling and seizure.

The thickness of these washers also plays a role in setting the internal gear backlash. ال FAW الروسية المحور التفاضلي الأمامي requires precise backlash to function correctly. Too much lash results in clunking and shock loads; too little causes binding and overheating. During assembly or rebuild, selecting the correct washer thickness is a precision task that defines the smoothness and longevity of the entire front axle system.

منطق التناوب: Bearings and Fasteners

Supporting the entire differential case as it rotates within the axle housing are the أسطواني مدبب وحدات (الجزء لا. 32214/YA6). These bearings are subjected to combined loads: the radial weight of the differential assembly and the axial thrust generated by the ring and pinion mesh. ال “YA6” suffix likely denotes a specific internal clearance or cage material optimized for the FAW الروسية المحور التفاضلي الأمامي. Correct preload on these bearings is essential to prevent the carrier from deflecting under load.

The attachment of the ring gear to the differential case is the most critical fastened joint in the entire axle. يستخدم التجمع 12 وحدات من Lock Bolt (الجزء لا. 2402063-557) for this purpose. These bolts must transmit the full driving torque of the engine. في FAW الروسية المحور التفاضلي الأمامي, these bolts are typically designed with a flange head to distribute pressure and are installed with a specific torque-plus-angle sequence.

إذا كانت هذه البراغي لتخفيف, the ring gear would wobble, destroying the pinion gear and potentially locking the front wheels. الهندسة القوية ل FAW الروسية المحور التفاضلي الأمامي fasteners ensures that this connection remains solid for the life of the vehicle, even under the punishing stop-start cycles of a mining truck. The material science behind these bolts prioritizes high tensile strength and resistance to shear forces.

انهيار المكون: 130. Front Axle Differential Assembly

| لا. |

رقم الجزء |

جزء اسم |

الكمية |

| 1 | 32214/YA6 | أسطواني مدبب | 2 |

| 2 | 2402063-557 | Lock Bolt | 12 |

| 3 | 2302037A820 | مدفوعة شطبة والعتاد – 1المحور الأمامي الحادي | 1 |

| 4 | 2303053-820 | غسالة – جير رمح المحور | 2 |

| 5 | 2303051-820 | جير رمح المحور | 2 |

| 6 | 2403061-A5D | رمح عبر – التفاضلي | 1 |

| 7 | 2403056-A5D | العتاد الكوكبي | 4 |

| 8 | 2403058-A5D | غسالة – العتاد الكوكبي | 4 |

| 9 | 2303023-820 | Lock Bolt | 8 |

| 10 | 2303024-820 | Lock Bolt | 4 |

| 11 | 2303015A820 | تجميع الحالة التفاضلية | 1 |

| 11-1 | 2303017A820 | الحالة اليسرى – التفاضلي | 1 |

| 11-2 | 2303018-820 | القضية الصحيحة – التفاضلي | 1 |

خاتمة: The Core of 6×6 مصداقية

ال FAW الروسية المحور التفاضلي الأمامي is the defining component that enables the CA3250P66K24L1TE5Z to operate effectively in the extreme conditions of the Russian North. Its robust design, featuring cold-tough case materials, precision-machined gears, and durable wear components, ensures that the front wheels contribute meaningful traction when it matters most. كل جزء, from the cross shaft to the lock bolts, plays a vital role in this synergy.

لفرق الصيانة, the lesson is one of precision and quality. Rebuilding a differential is a complex task where tolerances are measured in hundredths of a millimeter. Using generic gears or bearings risks catastrophic failure that can immobilize the truck. من خلال الاستثمار في حقيقية FAW الروسية المحور التفاضلي الأمامي عدة, operators ensure that their vehicle’s front drive system remains a reliable asset, capable of conquering the toughest terrain the planet has to offer.

التعبئة والتغليف والخدمات اللوجستية

أجزاء فاو, بما في ذلك مجموعة كتلة الأسطوانة, يتم تعبئتها بعناية لضمان الولادة الآمنة. يتم تأمين كل مكون في مواد واقية لمنع الضرر أثناء النقل. تضمن الشبكة اللوجستية الشحنات في الوقت المناسب في جميع أنحاء العالم, دعم عمليات الصيانة الفعالة. فيما يلي صورة توضح العبوة القياسية لقطع غيار شاحنات FAW, إظهار الاهتمام بالتفاصيل في التعامل والتخزين.

يقلل أسلوب التغليف هذا من مخاطر التآكل أو التلف الناتج عن الصدمات, ضمان وصول أجزاء مثل FAW Cylinder Block Assembly في حالة ممتازة. يمكن للعملاء الاعتماد على الخدمات اللوجستية التي تقدمها FAW للحصول على الجودة والموثوقية المتسقة.