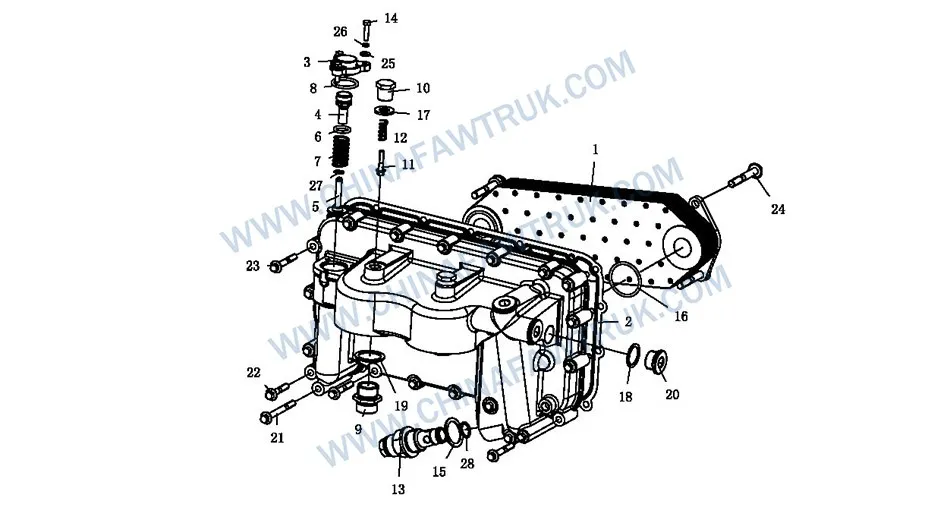

Refroidisseur d'huile moteur russe FAW: 28 Composants vitaux pour une régulation thermique suprême

Le Refroidisseur d'huile moteur russe FAW is the thermal equilibrium device for the CA3250P66K24L1TE5Z heavy-duty engine. It manages the delicate balance between rapid warm-up in Arctic conditions and efficient heat rejection under heavy loads. This guide dissects the complex valve logic, pressure regulation, and sealing architecture that define this essential system.

Refroidisseur d'huile moteur russe FAW

Heat Exchange Architecture: The Core Assembly

The foundation of the thermal management system is the Ensemble de refroidisseur d'huile (Partie no. 1013010-81D). Au sein du Refroidisseur d'huile moteur russe FAW architecture, this component utilizes a stacked-plate or shell-and-tube design to maximize the surface area available for heat transfer. As hot oil circulates through the core, it sheds thermal energy into the engine coolant, which is then managed by the radiator.

In the extreme cold of the Russian Federation, the material composition of the housing is critical. It must withstand the thermal shock of hot oil entering a sub-zero aluminum casting without cracking. Le Refroidisseur d'huile moteur russe FAW is engineered with reinforced ribbing to handle these internal stresses, ensuring structural integrity during the rapid heating cycles of a morning startup.

Sealing this unit to the engine block requires the Oil Cooler Body Gasket (Partie no. 1013012-81D). This is not a standard paper gasket; it is a high-performance composite designed to resist oil saturation and thermal degradation. If this gasket fails, high-pressure oil can leak externally or, pire, cross-contaminate with the coolant system, menant au redoutable “milkshake” in the sump.

Le Refroidisseur d'huile moteur russe FAW system places a heavy reliance on the sealing quality of the Joint torique (Partie no. GB3452.1_46.2X3.55). Located at critical fluid junctions, these O-rings prevent fluid migration. Dans des conditions arctiques, inferior rubber seals become brittle and fail; FAW uses fluoro-elastomers that remain pliable at -40°C to maintain a hermetic seal.

Cold Start Protection: The Bypass Mechanism

Une caractéristique déterminante du Refroidisseur d'huile moteur russe FAW is its sophisticated bypass system. When the engine oil is cold and thick, forcing it through the fine passages of the cooler core creates dangerous backpressure. Le Soupape – Soupape de dérivation du refroidisseur d'huile (Partie no. 1013033-53D) is the safety mechanism that prevents the cooler from bursting under this pressure.

This valve is seated against the Siège de soupape – Soupape de dérivation du refroidisseur d'huile (Partie no. 1013032-53D). When the pressure differential exceeds a calibrated limit, le Printemps – Soupape de dérivation du refroidisseur d'huile (Partie no. 1013036A53D) compresse, allowing the cold oil to bypass the cooler entirely. This ensures that the engine bearings receive immediate lubrication, even if the oil is too viscous to pass through the heat exchanger.

The entire bypass assembly is contained by the Couvercle de soupape – Soupape de dérivation du refroidisseur d'huile (Partie no. 1013031-53D), sealed with a dedicated Joint torique – Couvercle de soupape (Partie no. 1013037-53D). Dans le Refroidisseur d'huile moteur russe FAW, maintaining the integrity of this bypass circuit is vital. If the valve sticks open, the oil never cools; if it sticks closed, the cooler core may rupture during a cold snap.

En plus, the system includes a secondary protection layer involving the Bypass Valve (Partie no. 1013052-53D) and its corresponding Siège de soupape (Partie no. 1013051-53D). This redundancy in the Refroidisseur d'huile moteur russe FAW design underscores the focus on reliability. FAW engineers recognize that in remote Russian logistics routes, a single point of failure cannot be allowed to disable the vehicle.

System Stability: Pressure Regulation Assembly

Maintaining consistent oil pressure is the primary function of the Pressure Regulating Valve Assembly (Partie no. 1013060-81D). Situated within the cooler housing, this component acts as the master controller for system pressure. Dans le Refroidisseur d'huile moteur russe FAW, this valve bleeds off excess pressure generated by the oil pump at high RPMs, returning it to the sump.

The precision of this valve determines the health of the engine. If the pressure is too low, bearings will touch metal-to-metal; if too high, seals will blow out. Le Refroidisseur d'huile moteur russe FAW uses a precision-ground piston and spring within this assembly to ensure a linear response to engine speed changes, preventing pressure spikes that could damage the cooler core.

Connections to the full-flow filter are managed by the Boulon de connexion – Full Flow Oil Filter (Partie no. 1013041-53D). These robust fasteners serve a dual purpose: securing the filter housing and providing a fluid passage. The metallurgy of these bolts in the Refroidisseur d'huile moteur russe FAW is toughened to resist the shear loads applied during filter removal and installation.

To seal the various ports and test points, l'assemblée utilise le Hexagon Socket Plug (Partie no. Q/WC3410_M27X1.5). These plugs are essential for diagnostic access. Mechanics can remove them to attach mechanical pressure gauges, allowing for verification of the Refroidisseur d'huile moteur russe FAW performance without disassembling the engine.

The Clamping Strategy: Boulons et rondelles

L'intégrité structurelle du Refroidisseur d'huile moteur russe FAW relies on a specific family of fasteners. The primary clamping load is provided by 16 unités du Boulon de bride hexadécimal (Rype R) (Partie no. Q1820855), supported by smaller quantities of varying lengths like Part No. Q18208100 and Q1821070. Le “Rype R” designation indicates a reduced shank or specific elasticity designed to maintain tension during thermal expansion.

La conception de la tête à bride élimine le besoin de rondelles séparées, providing a stable platform that resists vibration loosening. Ceci est crucial pour le Refroidisseur d'huile moteur russe FAW, which is bolted directly to the vibrating engine block. A loose bolt here would result in an immediate and massive oil leak.

Sealing the banjo connections and plugs requires a variety of copper washers, y compris le Rondelle en cuivre (Partie no. Q/WC3403_27X35) and smaller sizes like Q/WC3403_20X28. Dans le Refroidisseur d'huile moteur russe FAW système, copper is the material of choice because it work-hardens upon compression, forming a permanent seal that is immune to the freeze-thaw cycles of the Russian climate.

Smaller fasteners, comme le Boulon à tête hexagonale (Partie no. CQ1500625), secure the cover plates and valve housings. Combined with the Rondelle à ressort (Partie no. Q40306) et Machine à laver (Partie no. Q40106), these ensure that even the lightest components remain secure. Every bolt in the Refroidisseur d'huile moteur russe FAW is a critical component in the fight against oil loss.

Liste de répartition des composants

The following table details the comprehensive 28-part breakdown for the Refroidisseur d'huile moteur russe FAW. Using the exact part numbers is mandatory to ensure the pressure ratings and thermal properties match the OEM specification for the CA3250P66K24L1TE5Z.

| Non. |

Numéro de pièce |

Nom de la pièce |

Quantité |

| 1 |

1013010-81D |

Ensemble de refroidisseur d'huile |

1 |

| 2 |

1013012-81D |

Oil Cooler Body Gasket |

1 |

| 3 |

1013031-53D |

Couvercle de soupape – Soupape de dérivation du refroidisseur d'huile |

1 |

| 4 |

1013032-53D |

Siège de soupape – Soupape de dérivation du refroidisseur d'huile |

1 |

| 5 |

1013033-53D |

Soupape – Soupape de dérivation du refroidisseur d'huile |

1 |

| 6 |

1013034-53D |

Joint torique – Soupape de dérivation du refroidisseur d'huile |

1 |

| 7 |

1013036A53D |

Printemps – Soupape de dérivation du refroidisseur d'huile |

1 |

| 8 |

1013037-53D |

Joint torique – Couvercle de soupape |

1 |

| 9 |

1013041-53D |

Boulon de connexion – Full Flow Oil Filter |

2 |

| 10 |

1013051-53D |

Siège de soupape |

2 |

| 11 |

1013052-53D |

Bypass Valve |

2 |

| 12 |

1013053A53D |

Printemps |

2 |

| 13 |

1013060-81D |

Pressure Regulating Valve Assembly |

1 |

| 14 |

CQ1500625 |

Boulon à tête hexagonale |

3 |

| 15 |

CQ72322 |

Laveuse de scellage |

1 |

| 16 |

GB3452.1_46.2X3.55 |

Joint torique |

2 |

| 17 |

Q/WC3403_20X28 |

Rondelle en cuivre |

2 |

| 18 |

Q/WC3403_27X35 |

Rondelle en cuivre |

3 |

| 19 |

Q/WC3403_30X40 |

Rondelle en cuivre |

2 |

| 20 |

Q/WC3410_M27X1.5 |

Hexagon Socket Plug |

3 |

| 21 |

Q18208100 |

Boulon de bride hexadécimal (Rype R) |

3 |

| 22 |

Q1820845 |

Boulon de bride hexadécimal (Rype R) |

1 |

| 23 |

Q1820855 |

Boulon de bride hexadécimal (Rype R) |

16 |

| 24 |

Q1821070 |

Boulon de bride hexadécimal (Rype R) |

4 |

| 25 |

Q40106 |

Machine à laver |

3 |

| 26 |

Q40306 |

Rondelle à ressort |

3 |

| 27 |

Q43108 |

Bague de retenue élastique d'arbre |

1 |

| 28 |

Q7342422A |

Joint torique en caoutchouc |

1 |

Diagnostic Protocols for Thermal Health

Inspecter le Refroidisseur d'huile moteur russe FAW demande de la vigilance. Look for signs of external leakage around the Oil Cooler Body Gasket. Oil stains here can indicate loose bolts or a degraded gasket. Never attempt to stop a leak by over-tightening the bolts, as this can warp the aluminum housing. Plutôt, replace the gasket and torque to spec.

Internal leaks are more insidious. Check the engine coolant for an oily sheen, which indicates oil pressure is forcing lubricant into the water jacket past a failed Joint torique. Inversement, check the dipstick for “mayonnaise” sludge, a sign that coolant has breached the cooler core and entered the oil sump.

Enfin, verify the operation of the Bypass Valve. If the engine takes an unusually long time to reach operating oil temperature, the valve may be stuck open. If the oil filter canister bulges or bursts on a cold start, the valve is likely stuck closed. Regular oil analysis can detect the wear metals associated with these thermal failures before they destroy the engine.

Conclusion: The Thermostat of Lubrication

Le Refroidisseur d'huile moteur russe FAW is a sophisticated thermal management system that does far more than just cool oil. It regulates pressure, ensures cold-start safety, and protects the engine from thermal shock. Chaque composant, de la Pressure Regulating Valve Assembly to the specific copper washers, plays a vital role in this ecosystem.

For fleet owners operating in the unforgiving Russian climate, maintaining this assembly with genuine FAW parts is non-negotiable. Generic coolers often lack the internal reinforcement and precise valve calibration required to survive -40°C starts. En investissant dans l'authentique Refroidisseur d'huile moteur russe FAW, you ensure that your fleet remains reliable, efficace, and profitable, regardless of the weather.

Emballage et logistique

Pièces FAW, y compris l'ensemble bloc-cylindres, sont emballés avec soin pour garantir une livraison en toute sécurité. Chaque composant est sécurisé dans des matériaux de protection pour éviter tout dommage pendant le transport. Le réseau logistique garantit des expéditions ponctuelles dans le monde entier, soutenir des opérations de maintenance efficaces. Vous trouverez ci-dessous une image illustrant l'emballage standard des pièces de camion FAW., mettant en valeur l’attention portée aux détails dans la manipulation et le stockage.

Cette approche d'emballage minimise le risque de corrosion ou de dommages causés par les chocs., s'assurer que les pièces comme l'ensemble bloc-cylindres FAW arrivent en parfait état. Les clients peuvent compter sur la logistique de FAW pour une qualité et une fiabilité constantes.